Chargers are essential tools in our daily lives, powering smartphones, tablets, laptops, and other devices. Yet, many people experience the frustration of a charger that works perfectly one day and fails completely the next. Unlike batteries, which degrade gradually, chargers often stop functioning without warning—leaving users stranded and searching for replacements. Understanding the root causes behind sudden charger failure is key to extending their lifespan and avoiding unnecessary expenses. This article explores the technical and behavioral factors that contribute to charger breakdowns and provides practical, science-backed strategies to keep your charging equipment reliable over time.

The Hidden Forces Behind Charger Failure

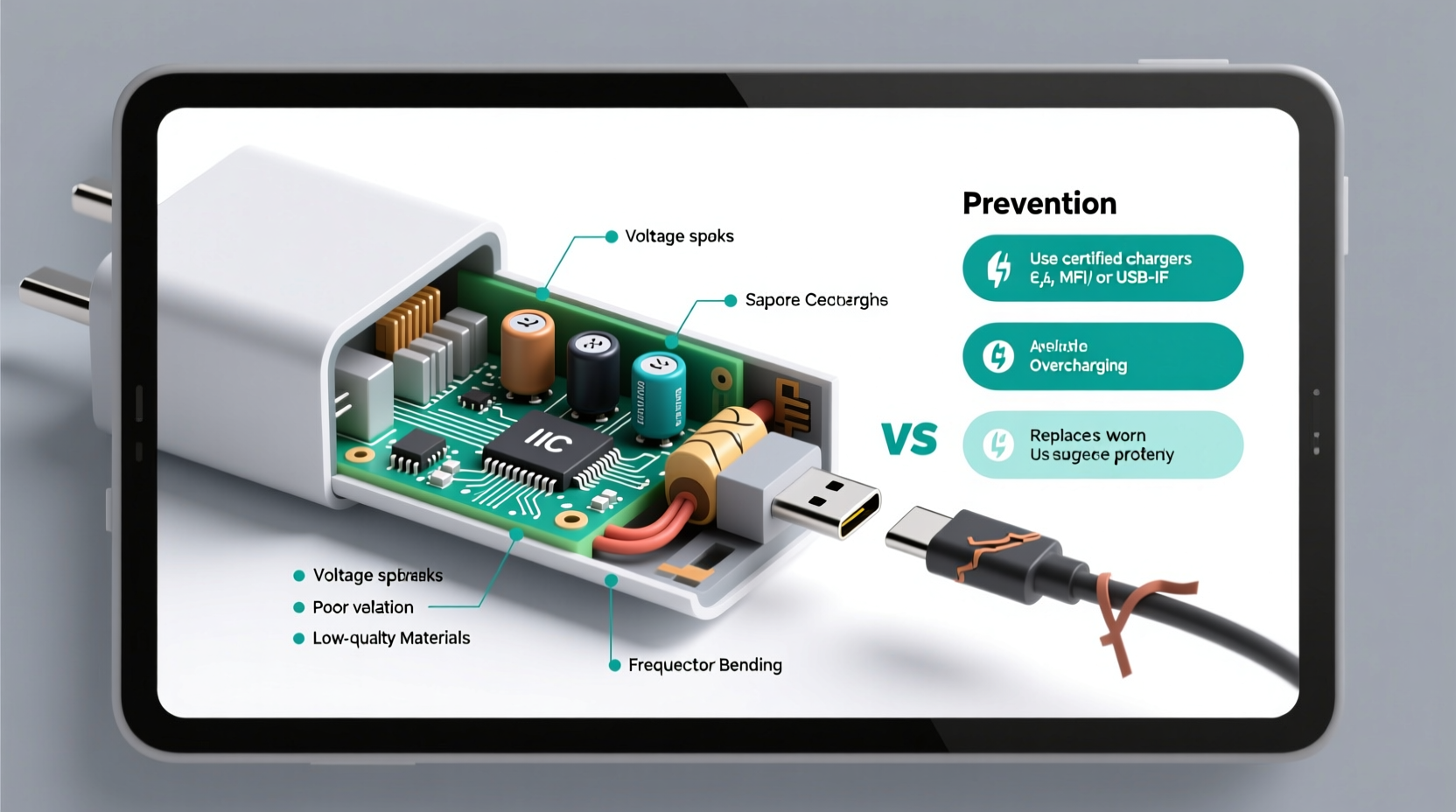

While chargers appear simple, they contain intricate circuitry designed to convert alternating current (AC) from wall outlets into direct current (DC) suitable for electronic devices. A sudden malfunction isn’t always due to a single event but rather the culmination of stressors that degrade internal components over time. Common culprits include voltage spikes, poor manufacturing, physical strain on cables, and exposure to environmental hazards such as moisture or extreme temperatures.

One of the most frequent issues occurs at the cable’s weakest point: the junction between the plug and the cord. Repeated bending, twisting, or pulling places mechanical stress on internal wires, eventually causing them to fray or disconnect. Once continuity is broken, power transmission stops entirely—even if the rest of the charger remains functional. Additionally, low-quality materials used in budget chargers accelerate this wear, making them more prone to early failure.

Environmental and Usage Habits That Shorten Lifespan

User behavior plays a significant role in how long a charger lasts. Many everyday habits—seemingly harmless—contribute directly to premature failure. For instance, leaving a charger plugged in 24/7 exposes it to continuous electrical load and thermal cycling, which can degrade capacitors and insulation over time. Similarly, wrapping cables tightly around devices or stuffing them into bags creates micro-fractures in copper conductors, leading to intermittent connectivity before total failure.

Moisture is another silent killer. Using a charger in humid environments or near sinks increases the risk of corrosion inside USB ports and circuit boards. Even condensation from temperature changes can cause short circuits when power is applied. Dust accumulation inside charging ports also interferes with conductivity and generates heat during use, further stressing internal components.

“Most charger failures aren’t instantaneous—they’re the result of months of unnoticed abuse. The final ‘pop’ is just the last straw.” — Dr. Alan Zhou, Electrical Engineer & Power Systems Consultant

How Manufacturing Quality Impacts Reliability

Not all chargers are created equal. Original Equipment Manufacturer (OEM) chargers undergo rigorous safety testing and use higher-grade components like reinforced connectors, proper shielding, and overvoltage protection. In contrast, third-party or counterfeit chargers often cut corners to reduce costs. These may lack essential safety features, use undersized wires, or have poorly soldered joints that break under minimal stress.

A study by the UK’s Electrical Safety First found that nearly 40% of non-branded phone chargers failed basic safety tests, with risks ranging from electric shock to fire hazards. Poor insulation, inadequate grounding, and substandard transformers make these units unreliable and dangerous. While they might work initially, their lifespan is significantly shorter due to inferior design and material selection.

| Feature | OEM Chargers | Low-Cost Counterfeits |

|---|---|---|

| Cable Durability | Braided or reinforced sheathing | Thin plastic coating, easily cracked |

| Voltage Regulation | Precise output control | Fluctuating output, risk of device damage |

| Safety Certifications | FCC, CE, UL listed | Often unlisted or fake certifications |

| Lifespan (Average) | 2–4 years with regular use | 3–12 months |

Step-by-Step Guide to Extending Charger Life

Extending the life of your charger doesn’t require expensive tools or technical expertise. By adopting a few disciplined habits, you can dramatically improve reliability and avoid unexpected failures. Follow this sequence to protect your investment:

- Unplug gently: Always grasp the plug body—not the cord—when removing the charger from an outlet or device. Yanking by the cable damages internal wires.

- Store loosely: Wrap the cable in a loose coil or use a twist-tie method instead of tight wraps. Avoid kinking or folding at sharp angles.

- Keep it dry: Store chargers in a cool, dry place away from bathrooms or kitchens where humidity levels are high.

- Use surge protectors: Plug chargers into a surge-protected strip to guard against voltage spikes during storms or power grid fluctuations.

- Inspect regularly: Check for fraying, stiffness, or discoloration in the cable and plug. Replace immediately if any damage is visible.

- Limit constant connection: Unplug the charger from the wall when not actively charging to reduce thermal and electrical stress.

- Clean ports monthly: Use a dry toothbrush or compressed air to remove dust from device charging ports, ensuring clean contact.

Real-World Example: When a Charger Failed Mid-Trip

Sarah, a freelance photographer based in Portland, relied on her smartphone for client communication, GPS navigation, and photo editing while traveling across Oregon. On a weekend shoot in the mountains, her primary phone charger stopped working after just eight months of use. She had no backup and spent two days unable to charge her device—missing critical emails and losing access to digital maps.

Upon inspection, she noticed the USB-A plug was slightly bent and the cable showed signs of fraying near the connector. She recalled frequently rolling the cord tightly around her hand and tossing it into her camera bag alongside lenses and tripods. The physical trauma, combined with exposure to dew during outdoor shoots, likely caused internal wire separation and minor corrosion.

After replacing the charger with a certified OEM model and adopting better storage practices—including a padded cable organizer—she hasn’t had a failure in over 18 months. Her experience highlights how small changes in handling can yield major improvements in durability.

Prevention Checklist: Protect Your Chargers Daily

- ✅ Unplug by gripping the plug, not the cord

- ✅ Store cables in loose loops or with Velcro ties

- ✅ Keep chargers away from water, steam, and damp surfaces

- ✅ Use only certified chargers matching your device specs

- ✅ Clean charging ports every month

- ✅ Avoid covering chargers with fabric or placing under pillows

- ✅ Replace damaged cords immediately—don’t attempt DIY repairs

- ✅ Rotate between multiple chargers to reduce wear on one unit

Frequently Asked Questions

Why does my charger work sometimes but not consistently?

Intermittent charging usually indicates internal wire damage, especially near the plug ends. As the cable bends, broken strands momentarily reconnect. This is a sign the charger is failing and should be replaced to avoid potential short circuits or device damage.

Can using a fast charger reduce its lifespan?

Fast chargers are engineered to handle higher currents and include advanced thermal management. However, frequent use at maximum speed generates more heat, which accelerates wear over time. To balance speed and longevity, use fast charging when needed and switch to standard charging overnight or during extended use.

Is it safe to leave a charger plugged in all the time?

Modern chargers are designed to enter low-power standby mode when not in use, but leaving them plugged in constantly still subjects them to voltage fluctuations and environmental risks. It's safer and more energy-efficient to unplug them after charging completes, especially during thunderstorms or prolonged absences.

Expert-Backed Strategies for Long-Term Charger Health

Electrical engineers emphasize that prevention is far more effective than replacement. “The weakest link in any charger system is the cable,” says Maria Lin, a hardware designer at a leading consumer electronics firm. “We spend millions improving chip efficiency, yet users destroy cables within months through improper handling.” She recommends investing in braided or rubber-armored cables, which resist abrasion and flexing better than standard PVC-coated ones.

Additionally, consider using detachable cable systems like USB-C to USB-C with separate power adapters. If the cable fails, only that component needs replacement—saving money and reducing e-waste. Modular designs are increasingly common in premium brands and represent a smarter long-term approach to charging infrastructure.

Conclusion: Treat Your Charger Like the Precision Tool It Is

Chargers may seem disposable, but they’re sophisticated electronic devices vulnerable to misuse and environmental stress. Sudden failures are rarely random—they’re warnings of accumulated damage. By understanding the mechanics behind charger breakdowns and adopting thoughtful usage habits, you can prevent most issues before they occur. Choose quality over convenience, handle cords with care, and stay vigilant about signs of wear. These small actions add up to years of reliable performance and fewer mid-day power emergencies.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?