It’s a familiar holiday frustration: you plug in your favorite string of Christmas lights, and instead of a full, sparkling display, only half the strand lights up. The rest remain dark, dulling the festive mood. This phenomenon—partial strand failure—is one of the most common issues with traditional incandescent and even some LED mini-light sets. While it may seem like the entire string needs replacing, the truth is that many cases can be diagnosed and repaired with basic troubleshooting. Understanding why this happens and how to address it can save time, money, and seasonal stress.

The Science Behind Christmas Light Circuits

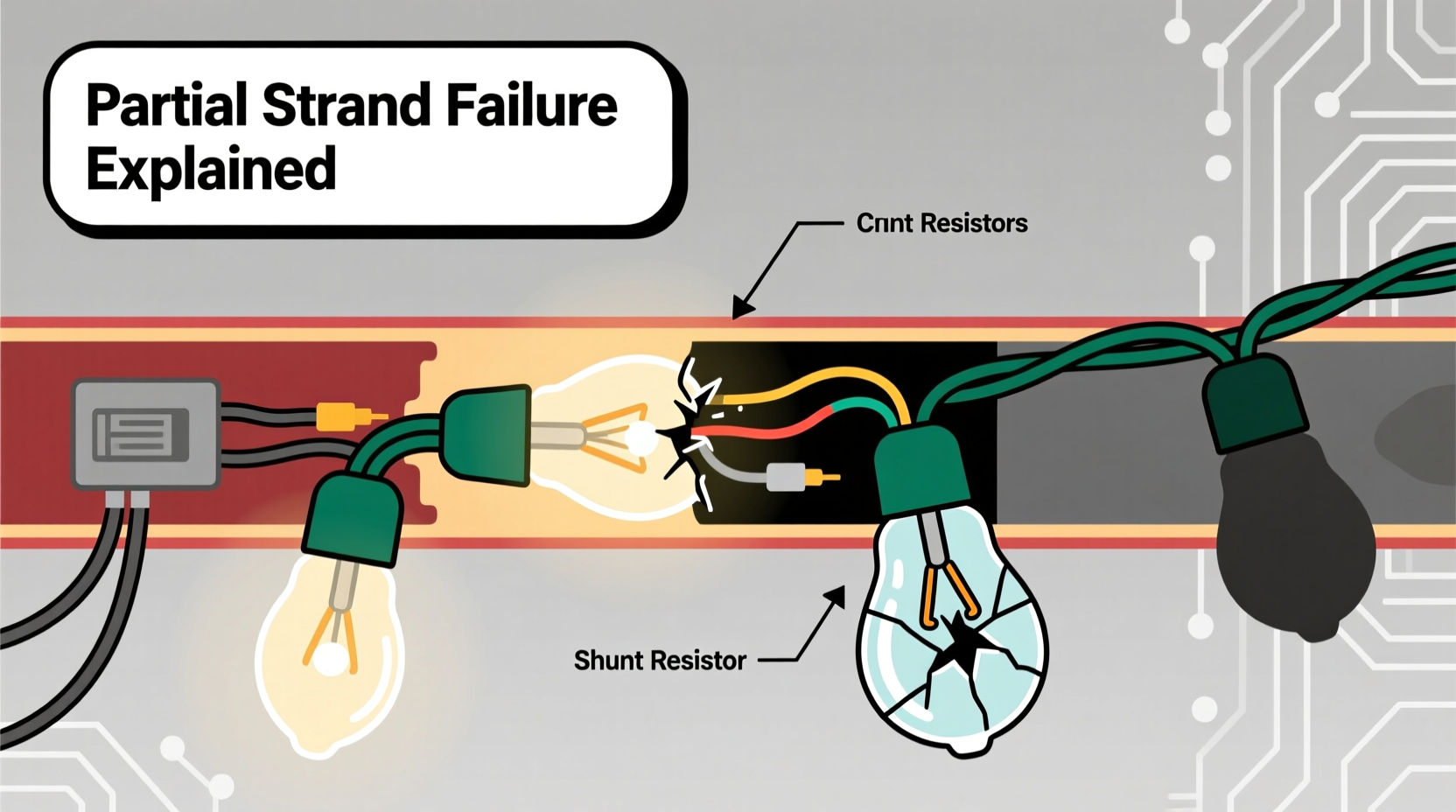

Most traditional Christmas light strands operate on a series circuit design. In a series circuit, electricity flows through each bulb in sequence. If one bulb fails or becomes loose, the circuit breaks, and power stops flowing to all bulbs downstream. However, modern mini-lights often use shunted sockets—small conductive pathways built into the socket—that allow current to bypass a dead bulb. Despite this innovation, partial failures still occur due to various factors including manufacturing defects, environmental wear, and physical damage.

In many multi-light strings, especially those with 50 or 100 bulbs, the strand is divided into two parallel circuits. Each circuit powers half the lights. This explains why sometimes exactly half the strand works while the other half remains dark. When one circuit fails, the other continues to function, creating the illusion of “half-working” lights.

“About 70% of partial strand failures we see are due to a single faulty bulb or a broken shunt—not a complete wire fault.” — Greg Thompson, Electrical Technician & Holiday Lighting Specialist

Common Causes of Partial Strand Failure

Several factors contribute to why only part of a Christmas light strand illuminates. Identifying the root cause is essential before attempting repairs.

- Loose or burned-out bulb: Even with shunted sockets, a severely damaged or missing bulb can break the circuit if the shunt fails to activate.

- Blown fuse: Most plug-end connectors contain two small fuses (usually rated at 3–5 amps). One protects each parallel circuit. A surge or short can blow one fuse while leaving the other intact, resulting in half the lights working.

- Damaged wiring: Pinched, chewed, or cracked insulation can interrupt continuity in one leg of the circuit, especially near the middle of the strand where wires split.

- Poor socket connection: Corrosion, bent contacts, or debris in the socket can prevent proper electrical contact.

- Moisture intrusion: Outdoor lights exposed to rain or snow may develop internal corrosion, particularly in older sets.

- Manufacturing defect: Some strands have weak solder joints or undersized wiring prone to early failure.

Step-by-Step Guide to Fixing Half-Working Christmas Lights

Restoring full functionality to a partially working strand is often achievable with patience and attention to detail. Follow this systematic approach:

- Unplug the strand and inspect the plug end. Locate the small sliding door on the male plug housing. Open it carefully using a flat screwdriver or fingernail.

- Check both fuses. Most strands have two fuses—one for each circuit. Use a fuse tester or multimeter to check continuity. Replace any blown fuse with an identical type (same voltage and amperage).

- Reconnect and test. Plug the strand back in. If both halves now light, the issue was fuse-related. If not, proceed.

- Divide and conquer visually. Identify where the working section ends. The problem typically lies at or just after the last lit bulb.

- Inspect each bulb in the non-working section. Remove bulbs one by one and examine for darkened filaments, cracks, or loose bases. Wiggle the bulb while it’s in the socket to test for intermittent connections.

- Test suspect bulbs. If you have a known working strand of the same voltage, insert the questionable bulb into a live socket to verify function.

- Check for shunt failure. In incandescent mini-lights, the shunt is a tiny wire wrapped beneath the filament leads. If corroded or broken, it won’t bypass a dead bulb. Look for gaps or discoloration.

- Use a light tester tool. Devices like the \"LightKeeper Pro\" send a pulse through the strand to clear shunt interruptions or detect open circuits without removing bulbs.

- Examine wire splits and junctions. Many strands split into two circuits midway. Inspect this area for cuts, rodent damage, or stress fractures in the wire insulation.

- Splice damaged wires (if necessary). For confirmed breaks, cut out the damaged section, strip the wires, and connect them using waterproof wire nuts or heat-shrink tubing. Ensure polarity is maintained if applicable.

If no single bulb or fuse resolves the issue, the problem may lie in a failed section of internal wiring or a defective socket cluster requiring replacement.

Tips and Best Practices for Prevention

Preventing partial strand failure starts with proper handling and maintenance throughout the year.

- Store lights in a dry, temperature-stable environment to prevent moisture buildup and plastic embrittlement.

- Avoid stacking heavy items on stored light boxes, which can crush sockets and crack wires.

- Inspect strands annually before use—check for frayed wires, cracked plugs, and corroded contacts.

- Replace older incandescent strands with commercial-grade LED strings, which are more durable, energy-efficient, and less prone to cascading failures.

- Use clips instead of nails or staples when installing outdoor lights to avoid piercing insulation.

| Issue | Quick Check | Solution |

|---|---|---|

| Only half lights work | Check fuses in plug | Replace blown fuse with correct rating |

| One bulb out kills entire section | Inspect shunt in dark bulb | Replace bulb or manually jump shunt |

| Flickering in half the strand | Wiggle bulbs and wires | Secure loose bulb or repair wire |

| No lights work after fuse check | Test continuity with multimeter | Trace break or replace strand |

| Outdoor strand fails intermittently | Check for moisture in sockets | Dry thoroughly; apply dielectric grease |

Mini Case Study: Reviving the Porch Light String

Martha from Ohio had used the same set of 100-count C7 Christmas lights on her front porch for seven years. Last season, she noticed only the first 50 bulbs illuminated. She replaced the fuses—no change. After reading online about shunted sockets, she began pulling each bulb from the dark half. On the 12th bulb, she noticed a blackened base and a broken filament. Upon closer inspection, the shunt underneath appeared corroded and separated. She replaced the bulb with a spare, and the entire second half lit up instantly. Martha later applied dielectric grease to all outdoor sockets before storing them, preventing future moisture-related issues.

This real-world example illustrates how a single compromised component can disable half a strand—even with protective shunts—and how methodical inspection leads to resolution.

LED vs. Incandescent: Which Is More Reliable?

While both types can suffer partial failure, their failure modes differ significantly.

Incandescent mini-lights are more susceptible to vibration, thermal stress, and filament burnout. However, their shunted design allows for some fault tolerance. In contrast, many budget LED strands are wired in series without effective bypass mechanisms. When one LED fails open-circuit, the entire section goes dark—even if the rest are functional.

Higher-end LED strings use rectifiers and parallel zoning to isolate failures. They also run cooler and consume less power, reducing stress on components. That said, cheaply made LEDs often have poor solder joints and thin wiring, making them vulnerable to cracking during flexing or cold weather.

“Modern LED technology has improved reliability, but only if you buy quality products. Avoid dollar-store light sets—they fail three times faster than name-brand versions.” — Lin Zhao, Consumer Electronics Engineer

FAQ

Can I connect half-working lights to another strand?

No. A partially failing strand may draw uneven current or create a short when linked. This can overload the good strand or trip household breakers. Repair or retire the faulty set first.

Why do my new LED lights only half work out of the box?

This usually indicates a manufacturing defect or shipping damage. Contact the retailer for a replacement. Do not attempt to modify sealed LED circuits unless you have electronics experience.

Is it safe to splice Christmas light wires?

Yes, if done properly. Use insulated connectors rated for low-voltage lighting, seal splices against moisture (especially outdoors), and ensure the repaired section isn’t under tension. Never splice beyond the original plug configuration.

Checklist: Diagnosing and Repairing Partial Strand Failure

- ✅ Unplug the light strand

- ✅ Open the plug fuse compartment

- ✅ Test both fuses with a multimeter or tester

- ✅ Replace any blown fuses with correct specs

- ✅ Plug in and test operation

- ✅ Visually identify the transition point between working and dead sections

- ✅ Remove and inspect each bulb in the non-working half

- ✅ Clean socket contacts if corroded

- ✅ Use a light tester tool to reset shunts (for incandescents)

- ✅ Examine mid-strand wiring splits for damage

- ✅ Splice broken wires securely if needed

- ✅ Retest fully before installation

Conclusion

Half-working Christmas lights are a common but solvable problem. Whether caused by a blown fuse, failed shunt, or damaged wire, most partial strand failures can be diagnosed and repaired with simple tools and careful observation. Understanding how series and parallel circuits function in holiday lighting empowers you to troubleshoot effectively and extend the life of your decorations. By adopting preventive habits—like annual inspections, proper storage, and using quality materials—you reduce future failures and enjoy brighter, more reliable displays year after year.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?