It’s a familiar holiday frustration: you plug in your Christmas lights, and only half of the string lights up. Unlike older series-wired strands where one dead bulb kills the whole circuit, modern lights typically use parallel wiring so that individual bulbs can fail without affecting others. Yet even in these systems, it's not uncommon for entire sections to go dark. The issue isn’t always a single bulb — it’s often something deeper within the electrical design or physical integrity of the strand. Understanding how parallel circuits behave in Christmas lights, what causes partial failure, and how to methodically troubleshoot the problem can save time, money, and seasonal stress.

How Parallel Circuits Work in Modern Christmas Lights

In traditional series circuits, electricity flows through each bulb in sequence. If one bulb burns out or becomes loose, the circuit breaks and the entire strand goes dark. Most vintage Christmas lights operated this way, requiring tedious bulb-by-bulb testing. Today, many manufacturers use parallel or shunted parallel designs, where each bulb has its own path to the power source. This means that if one bulb fails, the rest should stay lit — theoretically.

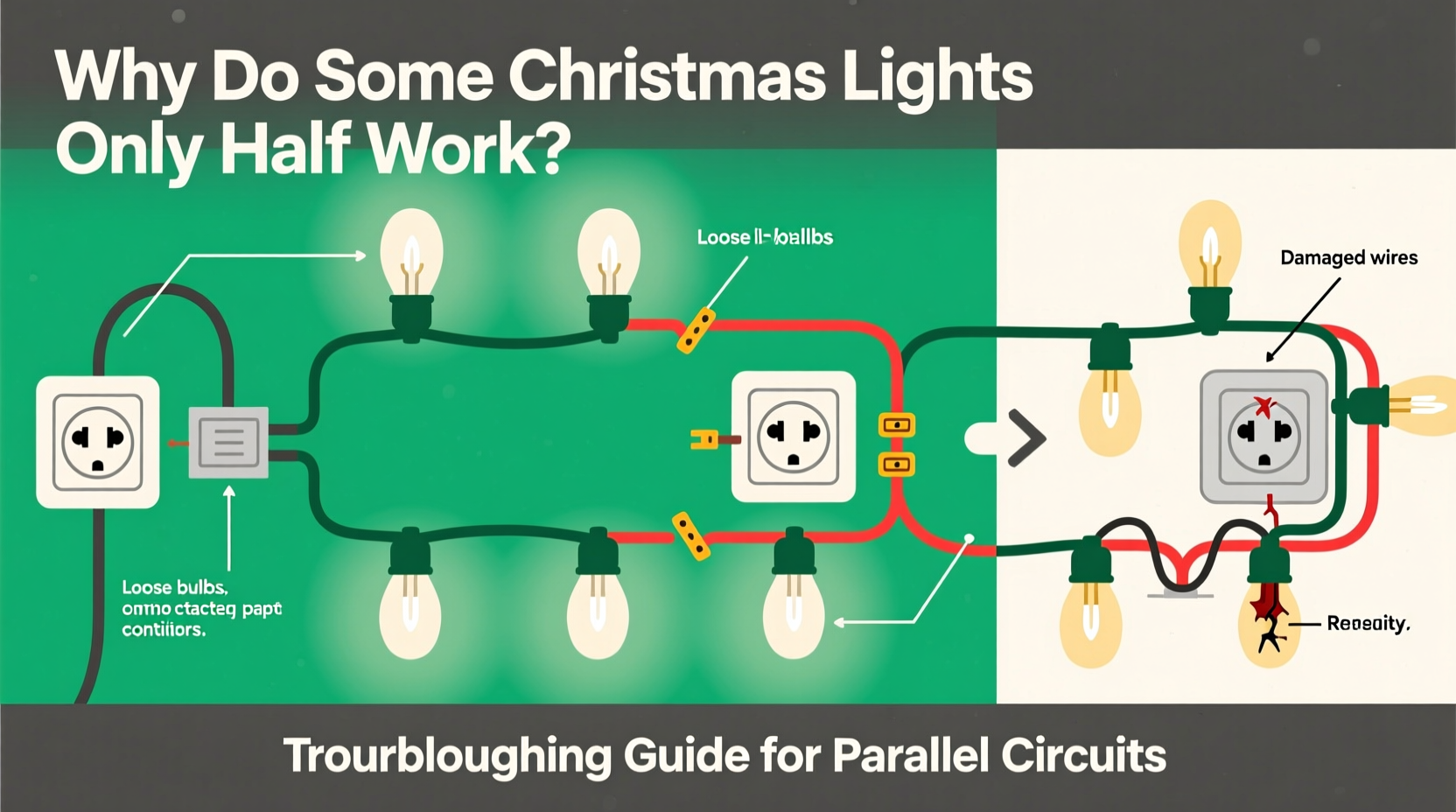

However, most “parallel” Christmas light strings aren’t fully independent at the bulb level. Instead, they’re segmented. A 50-light string might be divided into two banks of 25 bulbs wired in series, with those banks connected in parallel across the main power line. This hybrid approach reduces voltage drop while maintaining reliability. When only half the string lights up, it usually means one of these internal segments has failed — not the entire circuit.

“Modern mini-light strings are engineered for partial redundancy, but segment-level faults are still common due to manufacturing variances and environmental wear.” — Alan Reeves, Electrical Systems Engineer, Holiday Lighting Co.

Common Causes of Half-Working Christmas Light Strings

When part of a parallel-wired Christmas light string remains unlit, several potential culprits exist. Identifying the root cause requires understanding both the electrical layout and mechanical vulnerabilities of the strand.

- Blown fuse in one leg of the circuit: Many parallel strings have dual fuses — one for each side or segment. A blown fuse on one side will disable only half the lights.

- Loose or damaged wire connection at mid-string junction: Some strands have a visible connector halfway through. Corrosion, bending, or moisture ingress here can interrupt one parallel branch.

- Failed shunt in a series segment: Even in parallel designs, bulbs within a segment may be in series. If multiple bulbs fail or their shunts don’t activate, the whole segment drops out.

- Partial voltage loss due to degraded insulation or rodent damage: Chewed wires or cracked insulation can create high-resistance points that prevent full current delivery to one half.

- Outlet or extension cord issues: Sometimes the problem isn't the lights — it's an underpowered outlet or faulty extension cord delivering inconsistent voltage.

Step-by-Step Troubleshooting Guide for Partial Failures

Follow this systematic process to diagnose and repair a Christmas light string where only half works. This method applies specifically to parallel or segmented parallel circuits commonly found in LED and incandescent mini-lights.

- Unplug the string and inspect visually. Look for obvious signs of damage: kinks, cuts, melted sockets, or corroded connectors. Pay special attention to any midpoint connectors or splices.

- Check the fuses (if applicable). Most plug-end housings contain removable fuse caps. Use a small screwdriver to open the compartment. There may be two fuses — one for each parallel leg. Replace any visibly blown fuses with identical-rated ones (usually 3A or 5A, 125V).

- Swap the working and non-working halves mentally. Plug in the string and note which end stays lit. Now reverse the plug orientation in the outlet (if polarized, try a different outlet). If the same physical half stays dark regardless of plug direction, the fault is in the wiring or segment — not the outlet.

- Test continuity at the midpoint. If your string has a connector in the middle, disconnect it. Test each half independently on a known good outlet. The half that doesn’t light likely contains the fault.

- Inspect sockets in the dark half. Remove each bulb from the unlit section and examine the socket for corrosion, bent contacts, or debris. Reinsert firmly. Use a known-good replacement bulb to test each position.

- Use a voltage tester or multimeter. Set to AC voltage. With the string plugged in, carefully probe the input leads at the start of the dark segment. No voltage? The break is upstream. Voltage present? The issue is downstream — possibly a broken wire inside the insulation or a failed shunt cluster.

- Bypass suspect sections temporarily. If you're experienced with basic electrical work, you can splice around a damaged segment using waterproof wire nuts and heat-shrink tubing. Ensure power is off and never leave temporary fixes exposed outdoors.

Do’s and Don’ts When Repairing Parallel Light Strings

| Action | Recommended? | Reason |

|---|---|---|

| Replace fuses with same amperage rating | ✅ Yes | Prevents overcurrent risks and maintains circuit safety |

| Cut and re-splice wires with electrical tape | ❌ No | Tape degrades quickly; use wire nuts and weatherproof enclosures |

| Mix light sets from different brands | ❌ Avoid | Voltage and current specs may mismatch, causing overload |

| Use a light tester tool for socket diagnosis | ✅ Yes | Faster than manual bulb swapping; detects open circuits |

| Leave repaired strings exposed to rain | ❌ Never | Moisture increases shock risk and accelerates corrosion |

| Store lights coiled loosely in climate-controlled space | ✅ Yes | Reduces stress on wires and prolongs lifespan |

Real-World Example: The Case of the Faulty Connector

Diane in Portland purchased a 100-light LED Christmas string for her porch railing. Upon plugging it in, only the first 50 lights illuminated. She confirmed the outlet worked with other devices and noticed a small plastic connector about halfway through the strand. After unplugging, she disconnected the two halves and tested each separately. The front half lit up perfectly; the rear did nothing. Using a multimeter, she found no continuity across the male end of the rear segment. Closer inspection revealed a hairline crack in the connector housing, likely caused by being bent during last year’s storage. She replaced the rear section with a spare segment from an old set (same voltage), secured it with a waterproof junction box, and restored full lighting. Her solution avoided buying a new string and extended the life of her display.

Tips for Preventing Future Partial Failures

Prevention is more effective than repair when it comes to holiday lighting. These strategies help maintain consistent performance across parallel circuits year after year.

- Handle connectors gently. Avoid sharp bends or twisting at junction points — these are common failure zones.

- Use surge-protected outdoor outlets. Voltage spikes from storms or grid fluctuations can damage sensitive LED drivers in one segment.

- Don’t daisy-chain too many strings. Exceeding manufacturer limits (e.g., connecting more than 3–4 sets) can overload one leg of the circuit.

- Store lights on cardboard reels or in compartmentalized bins. Prevents crushing and tangling, which stresses internal wires.

- Retire strings older than 5 years. Insulation becomes brittle, increasing the risk of internal shorts and partial failures.

Frequently Asked Questions

Can one bad bulb cause half my lights to go out in a parallel circuit?

Not typically — unless that bulb is part of a series segment within a parallel bank. In segmented designs, a cluster of bulbs wired in series can fail as a group if multiple shunts don’t activate or if the filament break creates an open circuit.

Why do my lights work when I wiggle the middle connector?

This indicates a loose or corroded connection. The physical movement temporarily restores contact. Clean the pins with isopropyl alcohol and consider replacing the connector or sealing it with dielectric grease.

Is it safe to cut off a non-working half of a Christmas light string?

Only if you’re modifying the string for permanent shortening and rewiring the end cap properly. Never leave exposed conductors. If you remove a section, ensure the remaining half is still fused and insulated. For safety, it’s better to replace the entire string if damage is extensive.

Final Checklist: Restore Your Full Glow

Before declaring a light string beyond repair, run through this final checklist:

- ✅ Unplugged the string and inspected for visible damage

- ✅ Checked and replaced fuses if necessary

- ✅ Tested each half independently at midpoint (if applicable)

- ✅ Verified power delivery with a multimeter or tester

- ✅ Replaced suspect bulbs with known-working ones

- ✅ Ensured connections are clean, tight, and dry

- ✅ Confirmed compatibility when mixing brands or types

- ✅ Stored properly after repair for future use

Conclusion: Shine Brighter with Smarter Fixes

A Christmas light string that only half works doesn’t mean it’s time to throw it away. With a clear understanding of how segmented parallel circuits operate, and a methodical approach to diagnosis, most partial failures can be resolved quickly and safely. Whether it’s a blown fuse, a compromised connector, or a worn-out segment, the tools and knowledge to fix it are within reach. By applying these troubleshooting techniques and preventive habits, you extend the life of your decorations, reduce waste, and keep your holiday display radiant year after year.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?