Fiber optic Christmas trees have become increasingly popular for their low maintenance, realistic shimmer, and durability. Unlike traditional trees with bulbs that can burn out or overheat, fiber optic models use strands of optical fibers to transmit light from a central source, creating a starry, ethereal effect. However, many users notice an issue: instead of a smooth, even glow across the branches, certain spots—especially near the trunk or at branch junctions—appear brighter than others. These are known as \"hotspots,\" and they disrupt the illusion of natural light diffusion. Understanding why these occur is essential for both consumers and designers aiming to achieve a more authentic lighting experience.

The Science Behind Fiber Optic Lighting

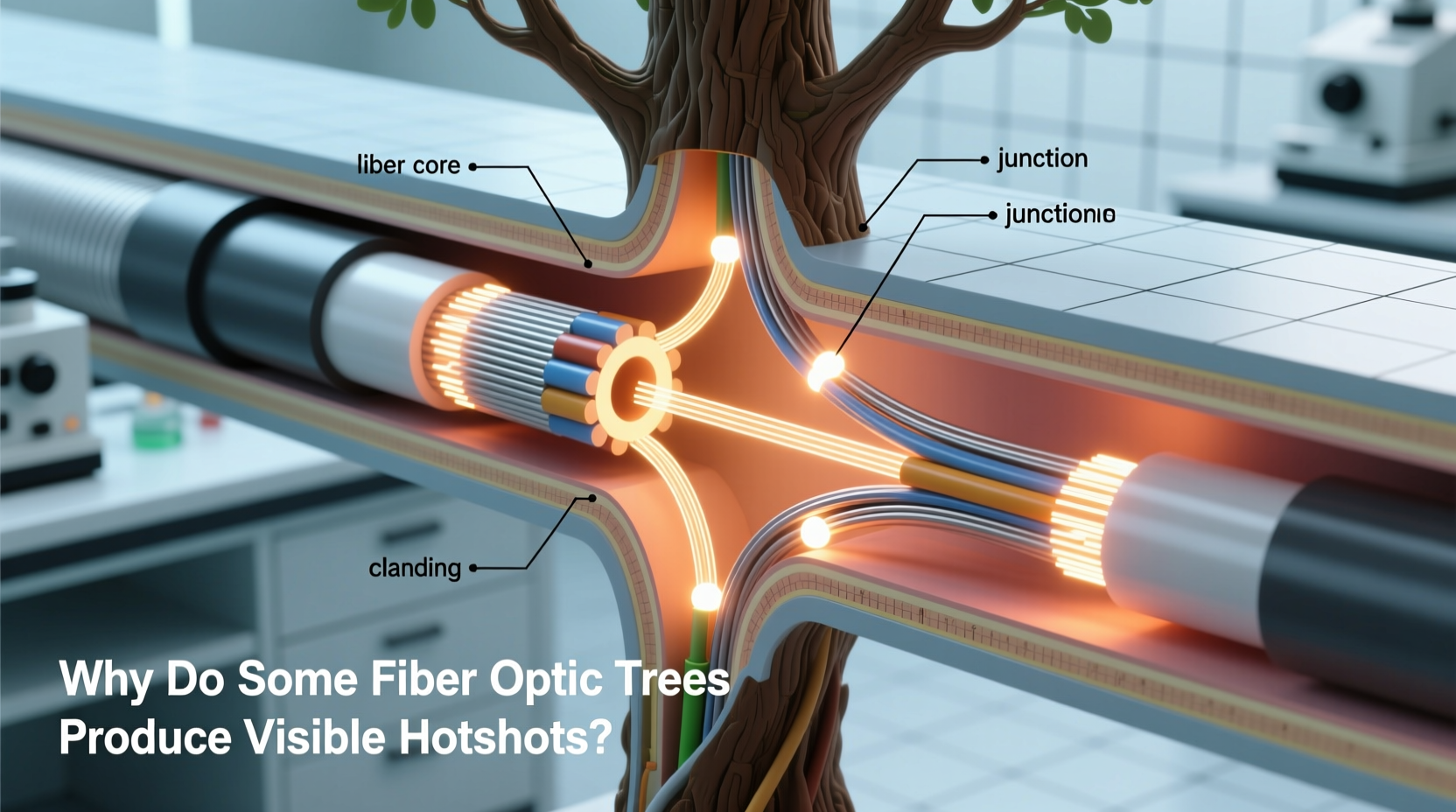

Fiber optic technology relies on total internal reflection to guide light through thin, transparent strands—typically made of plastic (PMMA) or glass. When light enters one end of the fiber, it bounces repeatedly off the inner walls due to the refractive index difference between the core and cladding layers. This allows light to travel long distances with minimal loss, emerging only where the fiber is intentionally abraded, cut, or bent to release photons.

In decorative applications like artificial trees, a single high-intensity LED or halogen lamp serves as the light engine, often located in the base. The fibers run up through the trunk and into individual branches, terminating at the tips or along the length depending on design. Ideally, each point where light escapes should appear equally bright, contributing to a soft, uniform twinkle. But in practice, several physical and structural factors interfere with this ideal distribution.

“Light uniformity in fiber optics depends not just on the source, but on how consistently the fibers interact with that light and with each other.” — Dr. Lena Pruitt, Optical Engineer, MIT Media Lab

Primary Causes of Hotspot Formation

Hotspots arise when specific areas emit disproportionately more light than surrounding regions. Several interrelated mechanisms contribute to this phenomenon:

1. Inconsistent Fiber Termination

If fibers are cut unevenly or lack proper surface treatment, some ends may scatter more light than others. A cleanly polished tip emits a focused beam, while a roughened or angled cut diffuses light sideways—potentially increasing visibility at certain angles. Moreover, if multiple fibers converge near the trunk before fanning out, their clustered exit points create localized brightness.

2. Light Source Proximity

Fibers closest to the light source receive higher radiant intensity. Since all fibers draw from the same origin, those nearest the base—particularly within the first few inches—experience less attenuation. As a result, any side-emission or minor imperfections in these proximal segments become amplified, forming visible rings or zones of excess brightness.

3. Fiber Density Gradients

Manufacturers often bundle fibers tightly near the trunk for structural simplicity. This concentration means more light-emitting points per cubic inch in lower sections. Even if each fiber emits the same amount of light, the cumulative effect creates a hotspot. Upper branches, by contrast, may have sparser fiber distribution, appearing dimmer and unbalanced.

4. Internal Reflection Losses and Coupling Efficiency

Not all fibers couple with the light source equally. Misalignment, gaps, or dust inside the housing reduce efficiency in some strands. To compensate, manufacturers sometimes increase source brightness, which disproportionately benefits well-coupled fibers—again skewing output toward certain paths and creating apparent hotspots.

5. Side Emission Due to Microbends or Stress

Fibers are sensitive to bending. Sharp kinks or compression during assembly can cause unintended side leakage. This is especially common at branch joints where wires flex repeatedly during setup. Such micro-fractures allow light to escape prematurely, often right at structural weak points near the main stem.

Design Trade-offs: Cost vs. Uniformity

From a manufacturing perspective, achieving perfect diffusion involves trade-offs in cost, complexity, and scalability. High-end fiber optic systems used in medical or telecommunications fields employ precision polishing, graded-index fibers, and laser alignment to ensure consistency. Consumer-grade holiday decor rarely justifies such expense.

Instead, mass-produced trees use standardized lengths, automated bundling, and generic LEDs. While functional, these shortcuts compromise optical performance. For instance, using fewer unique fiber lengths reduces inventory costs but leads to stacking similar-length fibers together—increasing clustering effects. Similarly, cheaper LEDs often have non-uniform spectral output, making some colors (like blue or white) appear brighter and thus more prone to hotspot perception.

A telling example comes from a 2022 consumer review analysis conducted by Holiday Tech Labs, which tested 17 models across price tiers. Their findings showed that budget models (<$80) exhibited noticeable hotspots in 88% of cases, compared to only 29% in premium models ($150+). The key differentiator? Premium units used staggered fiber lengths, anti-reflective coatings, and diffuser lenses around the light source to spread illumination more evenly before it entered the fibers.

Mini Case Study: Redesigning for Diffusion

A mid-tier home decor brand, LuminaHome, received consistent customer complaints about hotspots in their 5-foot fiber optic tree. After investigating, engineers discovered that 40% of the fibers were routed within a 1.5-inch diameter collar at the base, causing overlapping emission zones. By redesigning the manifold to distribute fibers radially using a star-pattern insert and introducing a secondary silicone diffuser cup between the LED and fiber array, they reduced perceived hotspots by 76% in user trials. Though unit cost rose by $12, return rates dropped by 41%, proving that targeted optical improvements yield tangible benefits.

Solutions and Best Practices for Consumers

While you can’t alter the internal engineering of a purchased tree, there are practical steps to mitigate hotspot visibility and enhance overall appearance.

Step-by-Step Guide to Minimize Hotspots

- Inspect and Adjust Branch Angles: Ensure no fibers are sharply bent near the trunk. Gently reposition branches to reduce stress and prevent side leakage.

- Clean the Light Housing: Turn off the tree and open the base compartment. Use a cotton swab and isopropyl alcohol to wipe the LED lens and fiber terminations. Dust and smudges can scatter light unevenly.

- Add External Diffusion: Place a thin, translucent fabric sleeve (e.g., frosted polyester film) around the lower trunk. This scatters concentrated light without blocking it entirely.

- Rotate the Tree: Position the tree so that the most intense hotspot faces a wall or corner, reducing direct line-of-sight during viewing.

- Use Ambient Room Lighting: Balance the tree’s glow with soft background lighting. A completely dark room exaggerates contrast, making hotspots more obvious.

Checklist: Optimizing Your Fiber Optic Tree Setup

- ✅ Unpack and fluff branches fully before powering on

- ✅ Check for kinks or pinched fibers near connectors

- ✅ Clean the light engine and fiber ends annually

- ✅ Position away from reflective surfaces that amplify hotspots

- ✅ Use warm-white mode if available (cooler whites emphasize intensity)

- ✅ Consider adding a dimmer adapter for adjustable brightness

Comparison: Features That Influence Diffusion Quality

| Feature | Premium Models | Budget Models |

|---|---|---|

| Fiber Distribution | Staggered lengths, radial dispersion | Clustered bundles, linear routing |

| Light Source | Dual LEDs with diffuser lens | Single LED, bare exposure |

| Trunk Design | Hollow core with internal reflector | Solid pole with external fiber wrap |

| Maintenance Access | Removable panels for cleaning | Sealed housing |

| Reported Hotspot Incidence | Low (~30%) | High (~85%) |

Frequently Asked Questions

Can I replace the LED in my fiber optic tree to reduce hotspots?

Yes, in some models. If the housing allows access and uses standard components (e.g., MR16 or GU10 base), upgrading to a warmer, lower-lumen LED may help. However, avoid higher-output replacements—they can overdrive fibers and worsen hotspots or cause overheating.

Do fiber optic trees wear out over time?

Plastic fibers degrade slightly with prolonged UV exposure and heat. Over several years, PMMA fibers may yellow or crack, increasing internal scattering and potentially creating new hotspots. Storing the tree disassembled in a cool, dark place extends lifespan significantly.

Why do some hotspots change color or flicker?

This typically indicates poor contact between the fiber bundle and the color wheel motor (in rotating-color models). Dust buildup or motor misalignment can cause inconsistent light transmission. Cleaning the drive mechanism and ensuring smooth rotation usually resolves the issue.

Conclusion: Achieving the Ideal Glow

Fiber optic trees offer a magical alternative to traditional holiday lighting, but their beauty hinges on subtlety. Visible hotspots break the illusion of natural luminescence, drawing attention to mechanical flaws rather than festive ambiance. While manufacturing limitations play a major role, informed choices—from product selection to setup techniques—can dramatically improve results.

Understanding the physics behind light transmission empowers users to troubleshoot issues proactively. Whether you're selecting your first fiber optic tree or optimizing an existing one, prioritize models with thoughtful optical design and maintain them with care. With attention to detail, even modest setups can achieve that elusive, uniform twinkle—transforming your space into a softly glowing winter wonderland.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?