LED lighting promised a revolution: energy efficiency, longevity, and consistent brightness. Yet many homeowners and facility managers report a quiet disappointment — their “long-life” LEDs gradually lose intensity, casting weaker light after just two or three years. This isn’t normal bulb burnout; it’s lumen depreciation — a measurable, often avoidable decline in light output. Unlike incandescent bulbs that fail suddenly, LEDs fade silently, compromising safety, visual comfort, and energy ROI. Understanding why this happens — and more importantly, how to stop it — separates thoughtful lighting decisions from costly, premature replacements.

The Science Behind LED Dimming: It’s Not Just “Wearing Out”

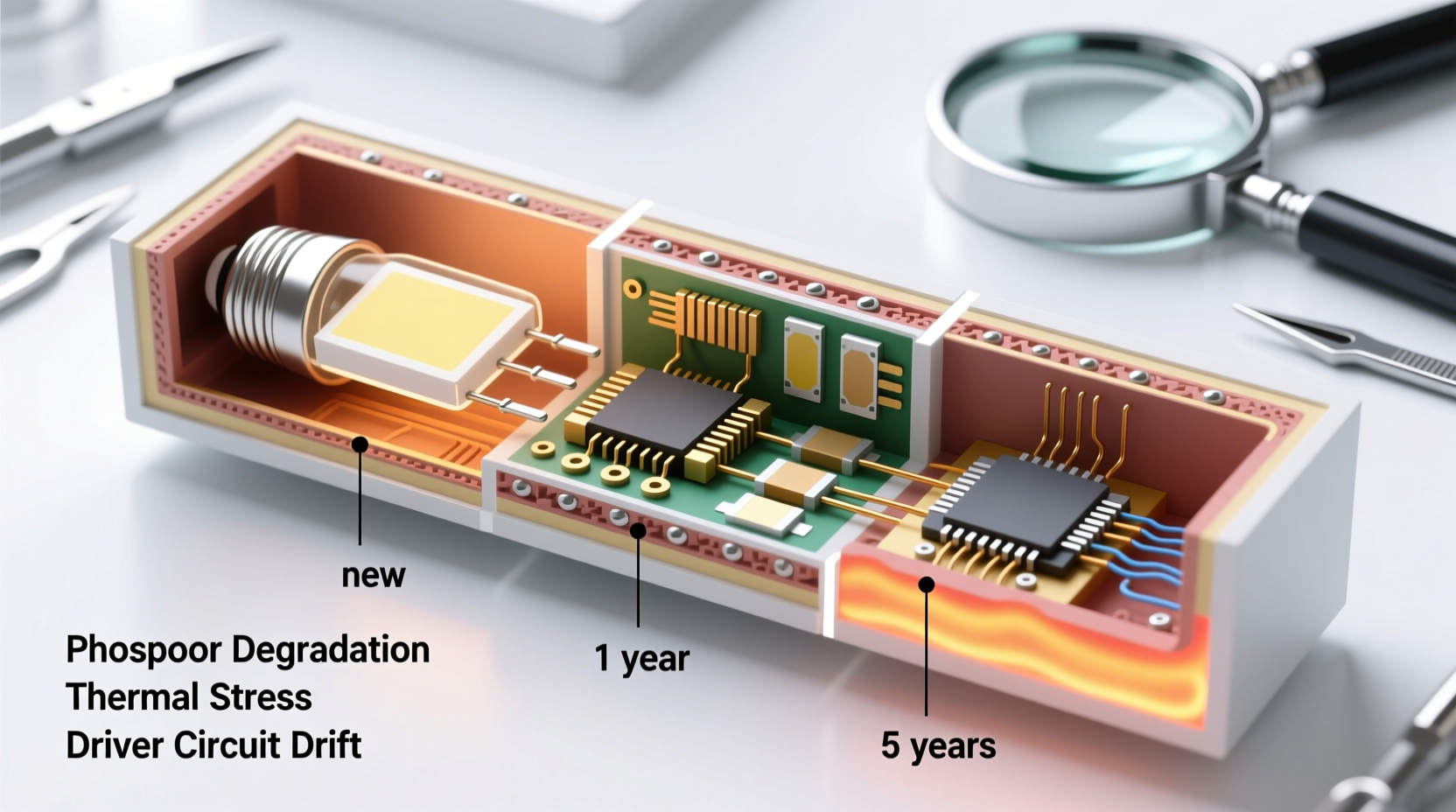

LEDs don’t dim because their semiconductor junctions “wear out” like filaments. Instead, lumen depreciation results from cumulative physical and electrical stresses. The Illuminating Engineering Society (IES) defines L70 — the point at which an LED emits only 70% of its initial lumens — as its practical end-of-life. Most quality LEDs are rated for L70 at 25,000–50,000 hours. But real-world performance often falls short, not due to inherent failure, but due to design compromises and environmental mismanagement.

Four primary mechanisms drive this decline:

- Phosphor degradation: White LEDs use blue chips coated with yellow phosphor. Heat and UV exposure cause phosphor particles to oxidize and crack, reducing conversion efficiency and shifting color temperature toward cooler, bluer light.

- Driver component aging: The electronic driver — which converts AC power to stable DC current — contains electrolytic capacitors, diodes, and thermal pads. Capacitors dry out over time, especially when overheated, causing current ripple and voltage instability that directly throttles LED output.

- Thermal stress on the chip: Every 10°C rise above the junction’s rated temperature accelerates lumen loss by up to 50%. Poor heatsinking, enclosed fixtures, or high ambient temperatures force the LED chip to operate hotter than designed, accelerating crystal lattice defects and reducing photon emission efficiency.

- Interconnect fatigue: Tiny wire bonds connecting the LED die to its package expand and contract with thermal cycling. Repeated expansion/contraction leads to micro-cracks, increasing resistance and creating localized hot spots that further accelerate degradation.

Crucially, these factors compound. A marginal heatsink raises junction temperature, which degrades phosphor faster and stresses the driver — a cascade effect that turns minor design oversights into rapid performance decay.

Design & Installation Mistakes That Accelerate Dimming

Many dimming issues stem not from product flaws, but from mismatched application. An LED rated for L70 at 50,000 hours assumes ideal conditions: 25°C ambient, open-air mounting, stable voltage, and proper driver matching. Real installations rarely meet those standards.

Common installation pitfalls include:

- Using non-dimmable LEDs on dimmer circuits — especially leading-edge (TRIAC) dimmers — causes inconsistent current delivery, overheating drivers and inducing flicker-induced thermal cycling.

- Overdriving LEDs with mismatched drivers (e.g., pairing a 350mA LED module with a 700mA constant-current driver) creates immediate thermal overload and irreversible flux loss within weeks.

- Mounting high-output LEDs in recessed downlights without adequate airflow traps heat in the housing, raising junction temperatures by 20–35°C above spec — cutting rated life in half.

- Ignoring voltage stability: In older buildings or rural grids, voltage spikes above 125V or sags below 105V force drivers to work outside their optimal range, accelerating capacitor aging and output drift.

A 2022 field study by the Pacific Northwest National Laboratory tracked 1,200 commercial LED troffers across 14 office buildings. Units installed in thermally unrestricted ceiling plenums retained 92% of initial lumens after 36 months. Identical models installed in tightly sealed, insulated ceiling cavities dropped to 74% — a 18% greater depreciation, directly attributable to enclosure-related thermal buildup.

Prevention Strategy: A 5-Point Maintenance & Selection Protocol

Preventing premature dimming requires proactive selection and disciplined maintenance — not just buying “high-quality” LEDs, but verifying how they’ll perform *in your specific environment*. Follow this evidence-based protocol:

- Verify thermal design data: Request the manufacturer’s TM-21-compliant lumen maintenance report and ask for the tested junction temperature (Tj) under your expected operating conditions — not just the ambient rating.

- Match drivers to load and environment: Use constant-current drivers for linear arrays and constant-voltage for tape lights. Ensure driver IP rating matches location (e.g., IP65 for damp basements, IP67 for outdoor signage).

- Install with thermal margins: Leave ≥2 inches of clearance around all high-output fixtures. Use thermally conductive mounting hardware (e.g., aluminum standoffs) instead of plastic clips for surface-mounted panels.

- Monitor voltage and waveform: Use a plug-in power quality analyzer for 72 hours before large-scale LED deployment. Reject any circuit with >3% total harmonic distortion (THD) or voltage variance exceeding ±5%.

- Schedule luminance audits: Measure light levels with a calibrated lux meter at six-month intervals for critical areas (e.g., stairwells, task lighting). A sustained drop >8% per year signals underlying thermal or driver issues needing correction.

Do’s and Don’ts: Practical Decision Guide

Choosing and maintaining LEDs involves nuanced trade-offs. This table distills industry best practices into actionable guidance:

| Action | Do | Don’t |

|---|---|---|

| Bulb Replacement | Select bulbs with LM-80 test reports (minimum 6,000 hours) and TM-21 extrapolation showing L70 ≥ 35,000 hrs | Choose based solely on lumens/watt or price — ignore thermal derating curves |

| Fixture Selection | Prioritize fixtures with aluminum extrusion heatsinks and visible thermal pad contact area ≥ 80% of PCB footprint | Accept plastic-bodied “integrated LED” fixtures for ambient lighting in living rooms or hallways |

| Dimming Setup | Use trailing-edge (ELV) dimmers with compatible LEDs; verify dimmer minimum load is ≤ 25% of total connected LED wattage | Assume “dimmable” label guarantees smooth operation — always test with your exact dimmer model first |

| Cleaning & Maintenance | Wipe lenses and reflectors quarterly with microfiber cloth and isopropyl alcohol (70%) to maintain optical clarity | Use abrasive cleaners, ammonia-based glass sprays, or compressed air — they scratch polycarbonate and degrade anti-reflective coatings |

| Voltage Protection | Install whole-house surge suppressors (UL 1449 Type 2) and consider point-of-use suppressors for sensitive LED circuits | Rely only on power strips with basic surge protection — most lack adequate clamping voltage for LED driver protection |

Real-World Case Study: The Warehouse Lighting Retrofit

A Midwest distribution center replaced 420 metal halide high-bays with 200W LED equivalents in 2020. Within 18 months, aisle lighting dropped noticeably — measured lux fell from 85 to 52 fc at floor level. Maintenance logs showed no failures, yet productivity complaints increased and night-shift injury reports rose 12%.

An engineering audit revealed three root causes: First, the selected fixtures used passive aluminum fins but were mounted directly against insulated roof decking, eliminating convection cooling. Second, the constant-current drivers were undersized, running at 94% capacity during summer peaks — elevating internal temperatures beyond rated limits. Third, the facility’s 480V/3-phase system had unbalanced legs, causing voltage ripple that destabilized driver regulation.

The fix was surgical: Replaced mounting brackets with 1.5-inch aluminum spacers to restore airflow; upgraded drivers to 150% capacity rating; and installed a three-phase balancing transformer. Post-correction, lux levels rebounded to 78 fc and have held steady for 22 months. Energy savings remained intact — proving that dimming wasn’t inevitable, but a symptom of overlooked system integration.

Expert Insight: What Industry Engineers Prioritize

“Lumen depreciation is rarely about the LED chip itself. In 87% of premature dimming cases we investigate, the culprit is either thermal management failure or driver mismatch. A $2 LED chip in a $200 thermal-managed fixture will outlast a $12 chip in a $40 plastic housing every time — because heat kills LEDs, not time.”

— Dr. Lena Torres, Principal Lighting Engineer, UL Solutions

Torres’ team analyzed over 3,000 field-failure reports between 2019–2023. Their data confirms that driver-related issues (capacitor failure, current regulation drift) account for 41% of premature dimming incidents, while thermal stress accounts for another 33%. Only 12% were traced to defective LED dies — underscoring that system design, not component quality alone, determines longevity.

Frequently Asked Questions

Can I clean LED fixtures to restore brightness?

Yes — but only the optics. Dust, grime, and fly specks on lenses and reflectors can reduce delivered light by 15–30%. Wipe with 70% isopropyl alcohol and a lint-free cloth. Do not attempt to disassemble or clean internal components — this voids warranties and risks electrostatic discharge damage to the LED array.

Why do some “identical” LED bulbs from the same brand dim at different rates?

Manufacturers often use binning — sorting LEDs by forward voltage, color point, and initial lumen output. Bulbs assembled from lower-bin chips may start at 92% of nominal output and depreciate faster under identical conditions. Premium lines use tighter binning and higher-grade phosphors, yielding more consistent long-term performance.

Does turning LEDs on/off frequently shorten their life?

No — unlike fluorescents, LEDs aren’t harmed by cycling. However, rapid on/off cycling (e.g., motion sensors triggering every 90 seconds) induces thermal shock in drivers and interconnects. For applications requiring >5 cycles/hour, specify LEDs rated for “high-cycle operation” with solid-state capacitors instead of electrolytic ones.

Conclusion: Light That Lasts Is a Choice, Not a Promise

LED dimming isn’t fate — it’s feedback. Each gradual loss of brightness signals a thermal imbalance, an electrical mismatch, or an environmental oversight. The technology exists to deliver stable, high-quality light for 15+ years: robust drivers with solid-state capacitors, precision-engineered heatsinks, rigorous LM-80/TM-21 validation, and voltage-stable infrastructure. What’s required isn’t new breakthroughs, but disciplined implementation — selecting products by verified performance data, not marketing claims; installing with thermal margins, not convenience; and monitoring output, not just waiting for failure.

Start today: Pull one LED fixture from a frequently used room. Check its model number, look up its LM-80 report online, and compare its rated L70 hours to its actual age. If the numbers don’t align, you’ve identified a gap — and an opportunity to upgrade smarter. Share your findings or questions in the comments below. Lighting professionals and fellow homeowners rely on real-world experience to make better choices — your insight could help someone avoid years of compromised illumination.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?