LED lighting has revolutionized energy efficiency, longevity, and brightness across homes, commercial spaces, and outdoor installations. Marketed as durable and long-lasting—often rated for 25,000 to 50,000 hours—many users are surprised when their LEDs flicker, dim, or stop working entirely after just a few weeks in cold environments. This premature failure is not always due to poor manufacturing alone. Cold weather introduces unique stressors that can compromise even high-quality LED systems if they’re not properly designed or installed for low-temperature operation.

Understanding the science behind cold-induced LED failures allows consumers and professionals alike to make smarter purchasing decisions and implement preventive measures. From component vulnerabilities to thermal expansion issues, this article breaks down the root causes and provides actionable solutions to keep your LED lighting performing reliably through winter months and beyond.

The Myth of “Cold Kills LEDs” — What Really Happens

A common misconception is that cold temperatures inherently damage LEDs. In reality, LEDs often perform better in cooler conditions than in heat. Unlike incandescent or fluorescent bulbs, which rely on heated filaments or gas excitation, LEDs generate light through electroluminescence in semiconductor materials—a process more efficient at lower temperatures.

So why do so many LED fixtures fail in winter? The issue isn’t the cold itself, but rather how various components within the LED system respond to rapid temperature changes, condensation, material brittleness, and power supply instability.

“Cold doesn’t kill LEDs—it exposes weak links in the design. A well-engineered fixture will thrive in sub-zero conditions.” — Dr. Alan Zhou, Electrical Engineer & Lighting Systems Researcher, National Institute of Sustainable Energy

The real culprits are often overlooked: driver circuits, housing materials, sealing integrity, and installation practices. These elements determine whether an LED setup survives freezing climates or succumbs prematurely.

Key Reasons Why Some LED Lights Fail Early in Cold Weather

1. Driver Circuit Sensitivity

The LED driver regulates voltage and current supplied to the diodes. Many budget-friendly LED products use drivers with electrolytic capacitors, which contain liquid electrolytes. When temperatures drop below freezing (0°C / 32°F), these liquids thicken or freeze temporarily, reducing capacitance and disrupting stable current flow.

This leads to flickering, delayed startup, or complete shutdown. While the capacitor may function again upon warming, repeated freeze-thaw cycles degrade its internal structure, shortening lifespan significantly.

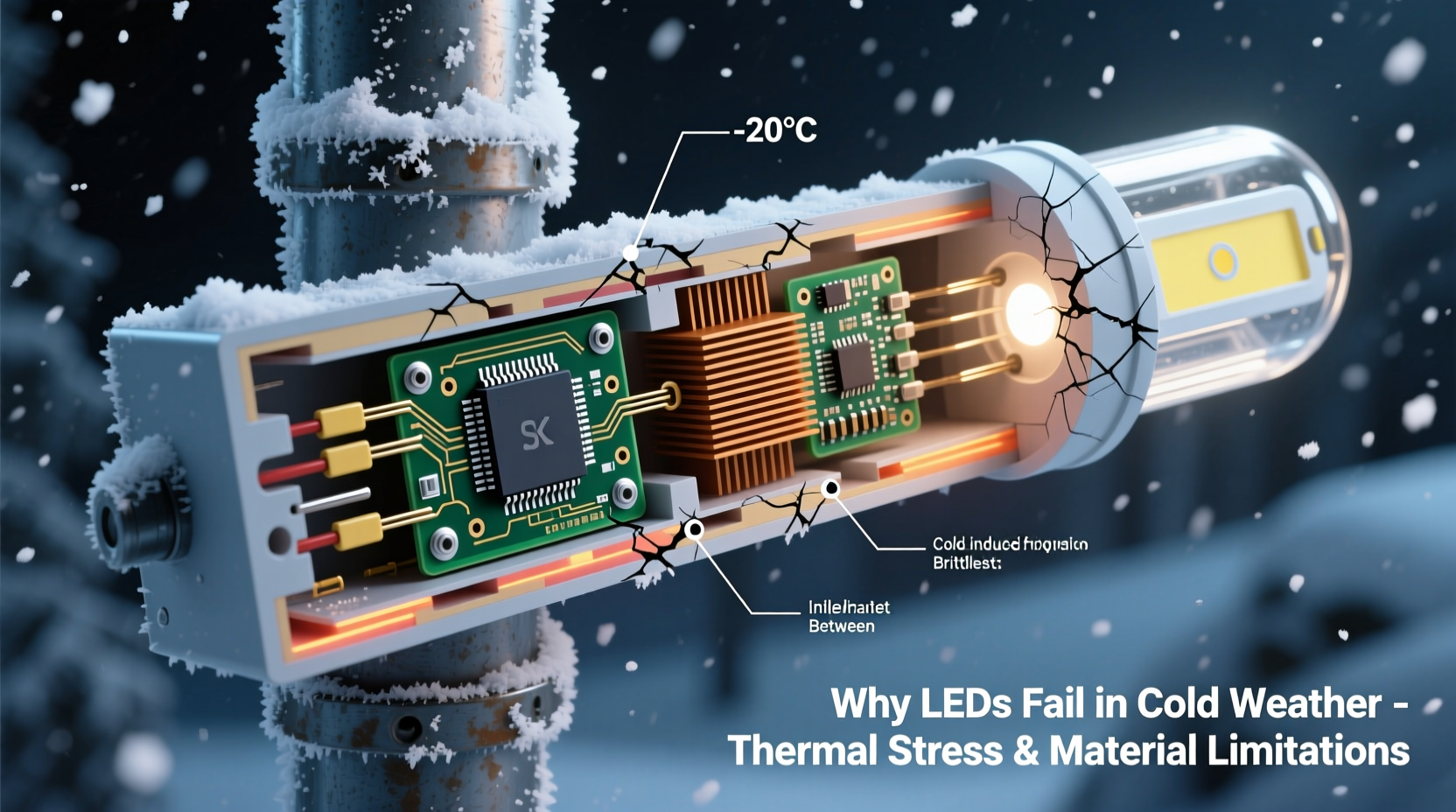

2. Thermal Expansion and Contraction Stress

Different materials expand and contract at different rates when exposed to temperature swings. In outdoor or unheated environments, daily fluctuations between daytime warmth and nighttime cold create mechanical stress on solder joints, circuit boards, and lens seals.

Over time, micro-cracks form in solder points or PCB traces, leading to intermittent connections or total circuit failure. This is especially problematic in cheaply assembled units where quality control during manufacturing was lax.

3. Moisture Ingress Due to Poor Sealing

Cold air holds less moisture, but when warm indoor air escapes into colder enclosures (like porch lights or garage fixtures), condensation forms inside the housing. If the seal is compromised—even slightly—this moisture can corrode electronics, cause short circuits, or promote mold growth on lenses.

Fixtures rated below IP65 (Ingress Protection) are particularly vulnerable. Outdoor-rated LEDs should meet at least IP65, with IP67 preferred for harsh climates.

4. Voltage Fluctuations in Winter Grids

Winter electrical demand spikes due to heating loads, causing voltage sags or surges in residential grids. Cheap LED drivers lack robust surge protection and voltage regulation. Repeated exposure to unstable input damages sensitive semiconductors over time.

This is especially noticeable in rural areas or older neighborhoods with inconsistent grid infrastructure.

5. Material Embrittlement

Plastic housings, diffusers, and gaskets made from low-grade polymers become brittle in sustained cold. Impact from wind-blown debris, ice buildup, or accidental bumps can crack the enclosure, exposing internal components to the elements.

Premium fixtures use polycarbonate or tempered glass with UV-stabilized rubber seals, which remain flexible down to -40°C (-40°F).

How to Prevent Early LED Failure in Cold Climates

Step-by-Step Guide to Cold-Weather LED Reliability

- Choose the Right Fixture Rating

Select LED lights explicitly rated for outdoor or low-temperature use. Check specifications for operating temperature range—look for models rated to at least -20°C (-4°F), ideally lower. - Verify Driver Quality

Opt for drivers using ceramic or polymer capacitors instead of electrolytic ones. These handle cold better and last longer. Manufacturers sometimes list “capacitor type” in technical datasheets. - Check Ingress Protection (IP) Rating

Use only IP65 or higher for outdoor applications. IP67 offers full dust resistance and temporary water submersion protection—ideal for snow-prone zones. - Install with Proper Ventilation and Drainage

Even sealed fixtures benefit from correct orientation. Mount downward-facing to prevent snow accumulation and allow any condensed moisture to drain naturally. - Use Surge-Protected Circuits

Install whole-home surge protectors or use individual surge-protected outlets for critical lighting circuits. This reduces risk from winter voltage spikes. - Avoid Mixing LED Brands on One Circuit

Different drivers react differently to cold starts. Mismatched response times can cause flickering or backfeeding issues. Stick to one brand or compatible model series per circuit.

Storage and Handling Before Installation

If storing LED fixtures before installation during winter, avoid leaving them in unheated garages or sheds for extended periods. Sudden transitions from extreme cold to warm indoor environments increase condensation risk inside packaging.

Instead, bring them indoors 24–48 hours before installation to acclimate gradually.

Do’s and Don’ts: Cold-Weather LED Best Practices

| Action | Do | Don't |

|---|---|---|

| Fixture Selection | Choose cold-rated LEDs with wide operating temps (-30°C to +50°C) | Assume all LEDs work in freezing temps |

| Capacitor Type | Prefer solid-state or film capacitors in driver | Rely on electrolytic capacitors in cold climates |

| Sealing | Use IP65+ rated fixtures outdoors | Install indoor-rated LEDs under eaves without protection |

| Installation | Ensure proper drainage; avoid upward-facing mounts | Ignore manufacturer mounting instructions |

| Maintenance | Inspect seals annually; clean lenses gently | Use abrasive cleaners or high-pressure washers |

Real-World Example: Municipal Streetlight Upgrade Gone Wrong

In early 2021, a mid-sized city in northern Minnesota replaced thousands of high-pressure sodium streetlights with new LED fixtures to cut energy costs. Within three months, over 18% of the newly installed units failed during a prolonged cold snap averaging -25°C (-13°F).

An investigation revealed that while the LEDs themselves were functional, the drivers used low-cost electrolytic capacitors not rated below -10°C (14°F). As temperatures dropped, the capacitors lost effectiveness, causing erratic behavior and eventual burnout. Additionally, several pole-top enclosures lacked adequate sealing, allowing snowmelt to enter and short-circuit wiring.

The city had to retrofit affected units with industrial-grade drivers and replace non-compliant fixtures at an additional cost of $1.2 million. The lesson? Specifications matter. Even large-scale projects can overlook environmental compatibility when prioritizing upfront savings.

Expert Tips and Maintenance Checklist

LED Cold-Weather Prevention Checklist

- ☐ Verify minimum operating temperature on product spec sheet

- ☐ Confirm IP65 or higher rating for outdoor use

- ☐ Ensure driver uses non-electrolytic capacitors (if specs available)

- ☐ Install fixtures facing downward to shed snow and moisture

- ☐ Use surge protectors on exterior circuits

- ☐ Inspect seals and housings every fall before winter begins

- ☐ Replace any cracked lenses or degraded gaskets immediately

- ☐ Avoid DIY modifications that compromise waterproofing

Frequently Asked Questions

Can cold weather permanently damage LED lights?

Yes—if the fixture isn’t designed for low temperatures. While LEDs themselves tolerate cold well, supporting components like drivers, capacitors, and plastic housings can fail due to freezing, condensation, or thermal stress. Permanent damage usually results from repeated exposure to incompatible conditions.

Why do my garage LED lights flicker when it's cold?

Flickering in cold weather typically indicates a struggling driver. Electrolytic capacitors lose efficiency below freezing, causing inconsistent current delivery. It could also signal moisture ingress or loose wiring exacerbated by contraction. Consider upgrading to cold-rated LEDs with industrial drivers.

Are there LEDs specifically made for freezer rooms or outdoor winter use?

Yes. Commercial and industrial suppliers offer “cold storage” or “arctic-grade” LEDs designed for freezers, refrigerated trucks, and outdoor signage in polar climates. These models use fully solid-state drivers, ruggedized housings, and operate reliably down to -40°C (-40°F).

Conclusion: Build Resilience Into Your Lighting System

Early LED failure in cold weather isn’t inevitable—it’s preventable. By understanding the vulnerabilities in driver design, material selection, and installation practices, you can choose lighting solutions built to endure. Don’t let marketing claims about “long life” override environmental suitability. Always check operating temperature ranges, IP ratings, and component quality before purchase.

Whether illuminating a backyard path, running a warehouse, or managing municipal infrastructure, investing in cold-ready LED technology pays off in reliability, safety, and reduced maintenance costs. The next time you shop for LEDs, ask: “Will this survive a real winter?”—then verify the answer in the specs.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?