Every holiday season, millions of households encounter the same frustrating ritual: a single dark bulb triggers a full string blackout. You check fuses, wiggle bulbs, swap them one by one—only to discover that half the strand won’t illuminate until you locate and replace that one faulty filament. This isn’t random bad luck. It’s physics, circuit design, and decades of cost-driven engineering converging in your living room. Understanding why this happens—and what you can actually do about it—goes far beyond seasonal troubleshooting. It’s about electrical safety, energy efficiency, longevity, and even fire prevention.

The Series Circuit Trap: Why One Bulb Takes Down the Whole Strand

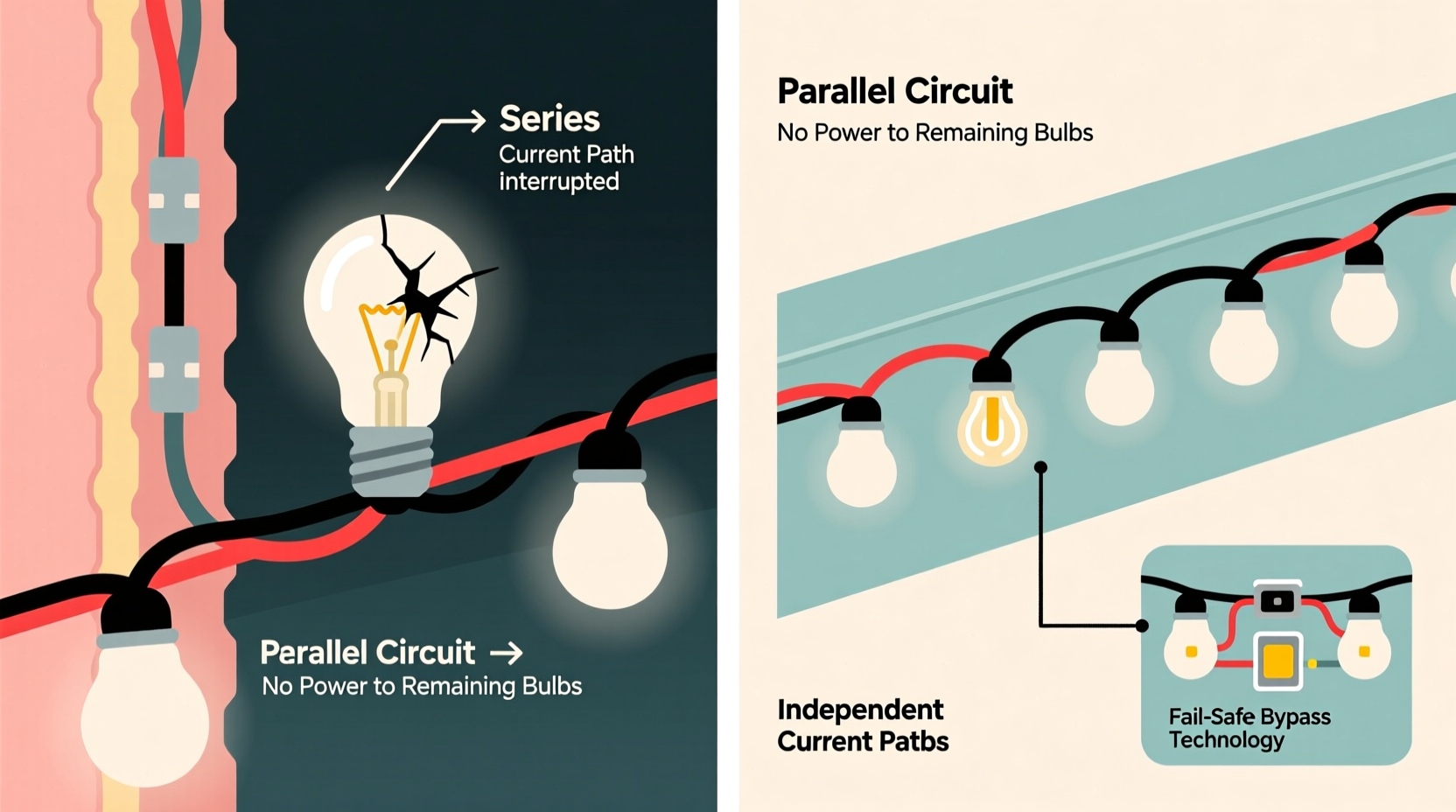

Most traditional incandescent mini-light strands (especially those manufactured before 2010) use a series circuit configuration. In this design, electricity flows through each bulb in sequence—like beads on a single thread. If any bulb’s filament breaks or its internal shunt fails to activate, the circuit opens and current stops flowing entirely. No current means no light—anywhere downstream.

Crucially, these bulbs contain a tiny bypass device called a shunt wire: a coiled strip of nickel-iron alloy wrapped around the filament supports. When the filament burns out, the resulting surge in voltage across the broken gap causes the shunt’s insulation to vaporize, allowing current to jump across and restore continuity. But shunts degrade over time. Moisture ingress, thermal cycling, manufacturing variances, and voltage spikes all reduce shunt reliability. Studies by Underwriters Laboratories (UL) show that only 68–79% of incandescent mini-lights successfully engage their shunts after filament failure—meaning over one in four bulbs leaves the entire string dark.

This vulnerability intensifies with age. A 5-year-old strand may have dozens of bulbs operating near end-of-life, each with a weakened shunt. One failure can cascade: as voltage redistributes across fewer remaining bulbs, their filaments experience higher-than-rated stress—accelerating burnout in adjacent units. The result isn’t just inconvenience—it’s a predictable, avoidable system collapse.

Modern Strand Designs: Where Technology Has Evolved

Not all strands behave the same way. Advances in LED technology and circuit architecture have introduced meaningful alternatives. Below is a comparison of common strand types and their failure behaviors:

| Strand Type | Circuit Design | Failure Behavior | Average Lifespan | Energy Use (per 100 bulbs) |

|---|---|---|---|---|

| Traditional Incandescent (pre-2010) | Full series | Entire string fails at first bulb outage; shunt reliability low | 2–3 seasons | 40W |

| Shunt-Optimized Incandescent (2010–2018) | Series with improved shunts | ~85% shunt activation rate; partial strings may stay lit | 3–5 seasons | 36W |

| LED Mini-Lights (basic) | Series-wired LEDs | Often fail open-circuit; some include parallel sub-circuits | 15,000–25,000 hrs | 4.8W |

| LED Mini-Lights (premium) | Parallel or segmented series-parallel | Only affected section dims/fails; rest stays lit | 25,000–50,000 hrs | 3.2W |

| Smart LED Strands (Wi-Fi/Zigbee) | Digital addressable (e.g., WS2812B) | No cascading failure; individual pixel control; self-diagnosing | 30,000+ hrs | 5–7W (full brightness) |

Note the critical distinction: “LED” alone doesn’t guarantee resilience. Many budget LED strands replicate the old series architecture—just with more efficient diodes. True fault tolerance requires intentional circuit segmentation or parallel wiring. Look for packaging terms like “cut-and-connect,” “sectional operation,” or “independent circuit zones.” These indicate engineered redundancy—not marketing fluff.

Prevention Strategy #1: Proactive Maintenance & Inspection

Waiting for failure invites chaos. A 10-minute inspection before each season prevents 90% of mid-holiday blackouts. Follow this step-by-step guide every October:

- Unplug and unwind: Lay the strand flat on a clean, dry surface. Never inspect while plugged in.

- Visual scan: Look for cracked bulbs, corroded sockets, frayed wire insulation, or discoloration near plug ends (a sign of overheating).

- Bulb rotation test: Gently twist each bulb ¼ turn clockwise and back. This reseats contacts and often restores connection in oxidized sockets.

- Shunt verification: Using a multimeter set to continuity mode, touch probes to both metal tabs at the bulb base. A working shunt reads <1Ω—even with a broken filament. No beep? Replace the bulb.

- Section testing: Plug in only the first 25 bulbs. If they light, unplug and add the next 25. Isolate the failing segment before replacing bulbs en masse.

Prevention Strategy #2: Smart Upgrades & Replacement Criteria

Replacing an aging strand isn’t an expense—it’s risk mitigation. Consider upgrading when any of these apply:

- Your strand is older than 5 years (incandescent) or 7 years (early LED)

- You’ve replaced >15% of bulbs in one season

- You notice flickering that persists after bulb replacement

- The strand lacks UL/ETL certification marks (look for “UL Listed” or “ETL Verified”)

When selecting replacements, prioritize three features: segmented circuits, built-in fuses, and IP44 or higher weather resistance (even for indoor use—humidity degrades contacts). Avoid “universal replacement bulbs”: mismatched voltage ratings or shunt profiles cause premature failure in neighboring sockets.

“Series-wired incandescents are fundamentally fragile. The industry shift to parallel-segmented LEDs wasn’t about brightness—it was about eliminating single points of failure. That’s not convenience—it’s electrical hygiene.” — Dr. Lena Torres, Electrical Safety Engineer, National Fire Protection Association (NFPA)

Real-World Case Study: The Community Center Cascade

In December 2022, Oakwood Community Center decorated its 40-foot entryway with eight 100-bulb incandescent strands wired end-to-end. On opening night, a single bulb failed near the third strand’s midpoint. Because all eight were daisy-chained in one continuous series, the entire 800-bulb display went dark. Volunteers spent 90 minutes diagnosing the issue—only to find the problem wasn’t the bulb, but a degraded shunt in a 2015-era strand that had been stored in a damp basement for three years. The shunt’s insulation had absorbed moisture, preventing voltage-triggered bypass. After replacing that one strand with a UL-listed, segmented LED alternative (with independent 25-bulb zones), the display operated flawlessly for 78 days—despite daily temperature swings from -5°C to 12°C. Total repair cost: $22. Total volunteer hours saved: 17.

Do’s and Don’ts: A Practical Checklist

- ✓ Test each strand separately using a dedicated outlet—never daisy-chain during testing

- ✓ Verify fuse integrity: Remove the plug’s sliding cover and inspect the 3AG glass fuse (typically 3A or 5A); replace if cloudy or with visible break

- ✓ Clean bulb bases with isopropyl alcohol and cotton swab to remove oxidation

- ✓ Use outdoor-rated extension cords (16 AWG minimum) for exterior displays

- ✗ Never tape over cracked bulbs or wrap bare wires with electrical tape as a “fix”

- ✗ Don’t exceed manufacturer’s maximum daisy-chain limit (e.g., “max 3 strands” means 3—not 5)

- ✗ Avoid hanging strands where they contact gutters, downspouts, or metal railings—galvanic corrosion accelerates failure

Frequently Asked Questions

Can I mix old and new strands on the same circuit?

No. Mixing incandescent and LED strands—even on separate plugs—creates load imbalance in shared circuits. More critically, combining different generations of series-wired strands increases the probability of shunt incompatibility. A newer bulb’s robust shunt may carry excess current meant for weaker older shunts, causing thermal runaway. Always group by manufacture year and technology type.

Why do LED strands sometimes flicker instead of going dark?

Flickering in LEDs usually signals a failing driver (the internal power converter), not bulb failure. Unlike incandescents, LEDs require precise DC voltage. As capacitors in the driver age, they deliver inconsistent current—causing visible pulsing. This is a warning sign: continued use risks complete driver failure or, in rare cases, thermal damage to the PCB. Replace the strand if flickering persists after checking connections and power supply.

Are battery-operated LED strands more reliable?

They eliminate outlet-related issues (voltage sags, surges), but introduce new failure modes: battery contact corrosion, inconsistent discharge rates across cells, and cold-temperature voltage drop. For reliability, choose lithium-ion rechargeables with built-in battery management systems (BMS)—not alkaline AA/AAA sets. Even then, wired strands with surge-protected outlets remain statistically more dependable for permanent installations.

Conclusion: Light Responsibly, Not Just Brightly

Strand light failure isn’t a quirk of holiday magic—it’s a symptom of outdated infrastructure meeting real-world wear. Every time you replace a bulb instead of upgrading the system, you defer a decision with tangible consequences: wasted electricity, increased fire risk, mounting frustration, and diminishing returns on seasonal joy. Modern lighting technology has moved decisively beyond the series-circuit paradigm. Segmented LEDs, smart diagnostics, and resilient materials exist not to dazzle—but to endure. Your lights shouldn’t demand detective work. They should simply work—season after season—with minimal intervention.

Start small this year: retire one aging strand. Choose a segmented LED replacement with clear circuit zoning. Perform that 10-minute pre-season inspection—not as a chore, but as stewardship. Notice how much calmer your December evenings become when the only decision you make is which color mode to select. That quiet reliability? That’s the real upgrade.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?