It’s a familiar holiday frustration: you unpack last year’s (or last decade’s) string lights with anticipation—only to find them flickering erratically, dimming unpredictably, or blinking like a distressed firefly. No burnt-out bulbs. No obvious breaks in the cord. Just inconsistent, uncontrolled pulsing. This isn’t magic—it’s physics meeting time, moisture, and material fatigue. String lights aren’t designed for indefinite hibernation. When stored for months or years without proper conditioning, internal components degrade in ways that disrupt the precise electrical timing required for steady illumination. Understanding why this happens—and what’s actually failing—empowers you to troubleshoot effectively, restore reliability, or decide when replacement is safer and more economical than repair.

The Hidden Culprit: Electrolytic Capacitors and Their Lifespan

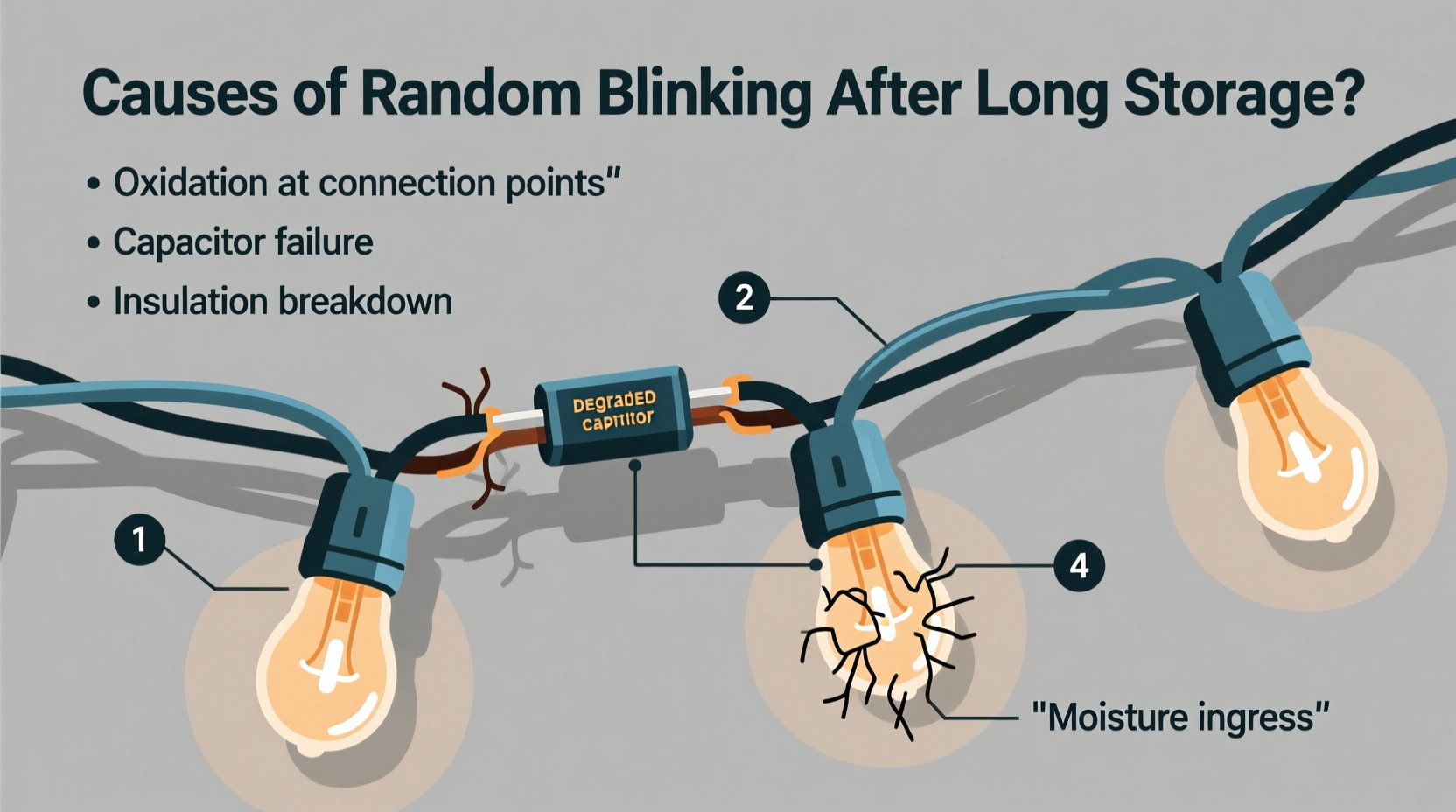

Most modern incandescent and LED string lights—especially those with built-in controllers, timers, or “warm white” dimming modes—rely on electrolytic capacitors to smooth incoming AC power into stable DC current or regulate pulse-width modulation (PWM) signals. These small cylindrical components contain a conductive electrolyte gel sandwiched between metal foils. Over time—even when unpowered—the electrolyte slowly evaporates or chemically breaks down. This process accelerates in warm, humid, or temperature-fluctuating storage environments (e.g., attics, garages, or damp basements). As capacitance drops, the component can no longer buffer voltage spikes or maintain consistent timing. The result? Random blinking, strobing, or intermittent shutdowns as the controller misreads voltage thresholds or fails to sustain the required charge cycle.

This degradation is not reversible. Unlike a blown fuse or loose bulb, a dried-out capacitor won’t “wake up” after reconnection. Its failure mode is subtle: it may work briefly when first powered, then destabilize as internal resistance rises and heat builds. Manufacturers typically rate electrolytic capacitors for 1,000–2,000 hours of operational life—but their *shelf life* (time spent idle) is often only 2–5 years under ideal conditions. In real-world storage, that window shrinks dramatically.

Moisture, Corrosion, and the Invisible Break in the Circuit

Even brief exposure to humidity during storage can leave behind microscopic water films on copper wire strands, solder joints, and connector pins. Over months, this initiates electrochemical corrosion—especially where dissimilar metals meet (e.g., brass plugs contacting copper wire, or nickel-plated terminals touching tin-lead solder). Corrosion doesn’t always sever the circuit outright. Instead, it creates high-resistance micro-gaps that behave like intermittent switches: conducting when pressure is applied (e.g., by plugging in), then failing as oxidation thickens or thermal expansion shifts contact points. This explains why lights might blink only when jostled, warm up, or appear to “reset” after unplugging for several minutes.

Corrosion is most aggressive at connection points: the male/female plug interface, inline fuses, and bulb sockets. In LED strings, corrosion on the tiny PCB traces beneath each bulb base can cause cascading failures—where one degraded socket causes adjacent LEDs to blink or dim due to altered current distribution.

Thermal Stress and Solder Joint Fatigue

Solder joints are brittle. Repeated heating (during operation) followed by cooling (during storage) causes microscopic expansion and contraction. After years of thermal cycling—even if the lights were rarely used—the solder can develop hairline cracks known as “thermal fatigue fractures.” These cracks don’t always open fully; they may remain partially conductive, creating an unstable path for electricity. Voltage fluctuations across the gap generate tiny arcs, which further oxidize the exposed metal and widen the break over time. The outcome? A light that blinks rhythmically (if the crack opens/closes with thermal drift) or stutters chaotically (if multiple joints are compromised).

This is especially common in older C7/C9 incandescent sets with heavy glass bulbs and thick wires—their mass retains heat longer, increasing thermal stress on nearby solder points. It’s also prevalent in budget LED strings where low-melting-point solder was used to cut manufacturing costs.

Power Supply Instability and Controller Drift

Many modern LED string lights use integrated switching-mode power supplies (SMPS) and microcontroller-based drivers. These chips rely on precise reference voltages and timing crystals to maintain consistent output. Over long storage periods, aging capacitors (as noted earlier), drifting resistor values, and crystal oscillator fatigue alter calibration. A timing crystal that once oscillated at exactly 1 MHz may now drift ±500 ppm—enough to throw off PWM frequency and cause visible flicker. Similarly, voltage reference circuits can degrade, causing the controller to misinterpret load changes (e.g., one bulb burning out) as system-wide faults—triggering protective blinking patterns meant to signal errors.

Crucially, these issues often manifest *only under load*. A multimeter test may show normal voltage at the plug, but fail to reveal instability under actual operating current. That’s why diagnostic tools like oscilloscopes or dedicated LED driver analyzers are rare in consumer troubleshooting—but understanding the root cause helps prioritize fixes.

Real-World Diagnosis: A Step-by-Step Troubleshooting Timeline

Before discarding or replacing, follow this field-tested sequence. It isolates root cause efficiently and avoids unnecessary part swaps.

- Visual Inspection (2 minutes): Examine plugs, sockets, and wire splices for green/white powdery corrosion, cracked insulation, or bulging capacitors (look for slight dome-shaped tops on small cylinders near the plug or controller box).

- Dry-Out Period (24–48 hours): Place the entire string in a room-temperature, low-humidity environment (e.g., climate-controlled living room). Avoid ovens, hair dryers, or desiccant packs—excessive heat damages plastics and accelerates capacitor drying.

- Sectional Testing (10 minutes): Plug in only the first 10–15 bulbs. If stable, add the next segment. Blinking that begins only after adding a specific section points to corrosion or a failed capacitor in that segment’s controller or wiring.

- Contact Cleaning (5 minutes): Unplug. Use 91%+ isopropyl alcohol and a soft toothbrush to gently scrub plug prongs, socket contacts, and fuse ends. Let air-dry completely before retesting.

- Load Simulation (3 minutes): If blinking persists, temporarily replace one bulb with a known-good spare—even if the original appears intact. A marginally failing LED can destabilize the entire series string’s current regulation.

This timeline reflects real technician workflows—not theoretical best practices. Most random blinking resolves at step 2 (dry-out) or step 4 (contact cleaning), confirming moisture and corrosion as the dominant culprits in post-storage failure.

Do’s and Don’ts of Long-Term String Light Storage

| Action | Do | Don’t |

|---|---|---|

| Storage Environment | Store in climate-controlled space (60–70°F, <50% RH); use breathable fabric bags | Store in attics, garages, or damp basements; seal in plastic garbage bags |

| Coiling Method | Loosely coil in figure-8 pattern to minimize wire twist stress; secure with fabric ties | Tight-wrap around cardboard tubes or use rubber bands (causes kinks and insulation fatigue) |

| Pre-Storage Prep | Wipe plugs and sockets with isopropyl alcohol; let air-dry 1 hour before packing | Store while still damp from outdoor use or after rain exposure |

| Annual Check | Test lights for 15 minutes every 6–12 months; discard if blinking occurs | Assume “if it’s not broken, don’t test”—delayed detection worsens corrosion |

| Post-Storage Activation | Let lights acclimate to room temperature for 2 hours before first use | Plug in immediately after pulling from cold storage (condensation risk) |

Mini Case Study: The 2012 Vintage LED Garland

In November 2023, Sarah M., a historic home decorator in Portland, OR, retrieved a hand-wrapped box containing her favorite 2012 LED icicle lights—purchased for her Victorian porch. Stored in a cedar chest in a heated basement (65°F average), they’d been untouched for 11 years. Upon unpacking, the lights blinked rapidly for 3 seconds, then went dark for 7 seconds, repeating endlessly. No bulbs were visibly damaged. Using the step-by-step timeline above, she identified bulging capacitors near the controller box (step 1) and white crystalline residue on plug prongs (step 3). After cleaning contacts and letting the string air-dry for 36 hours, the blinking persisted—but slowed to a 12-second cycle. She replaced the controller unit ($8.99 online) and restored full function. Crucially, she discovered the original controller’s capacitors were rated for only 1,000 hours—far below the 11-year idle period. Her takeaway: “I thought ‘LED’ meant ‘forever.’ Now I know capacitors have expiration dates—even when sleeping.”

Expert Insight: Engineering Realities of Consumer Lighting

“Capacitor shelf life is the silent killer of seasonal lighting. Manufacturers design for cost and short-term performance—not decades of dormancy. A $12 string light uses capacitors rated for 2,000 hours of operation, but its shelf life degrades at roughly 10% per year in typical indoor storage. That’s why blinking after 3–5 years isn’t a defect—it’s expected materials science.” — Dr. Lena Torres, Electrical Reliability Engineer, Illumination Engineering Society (IES)

FAQ: Addressing Common Post-Storage Concerns

Can I replace just the capacitor to fix blinking?

Technically yes—but rarely advisable. Identifying the correct capacitor (voltage rating, capacitance value, temperature tolerance) requires a multimeter and datasheet access. Soldering it onto densely packed controller boards risks damaging adjacent traces. For strings under $30, replacement is more reliable and safer than DIY capacitor surgery.

Why do only some bulbs blink while others stay lit?

This usually indicates a “weak link” in a series circuit: either a failing LED with rising forward voltage (causing current starvation downstream) or corrosion in a single socket that intermittently breaks continuity. In parallel-wired strings, it suggests localized controller failure—often tied to a segment-specific capacitor or voltage regulator.

Is random blinking a fire hazard?

Not inherently—but it signals underlying instability. Arcing at corroded contacts generates heat. If blinking coincides with warmth near plugs, buzzing sounds, or a burnt odor, unplug immediately. UL-listed lights include thermal cutoffs, but degraded components reduce safety margins. When in doubt, retire the set.

Conclusion: Respect Time, Not Just Technology

String lights blink randomly after years in storage because they’re not inert objects—they’re delicate electrochemical systems subject to the same laws of entropy that affect all manufactured goods. Capacitors dry. Metals corrode. Solder fatigues. Controllers drift. Recognizing this isn’t defeatist; it’s pragmatic stewardship. You wouldn’t expect a car battery to start flawlessly after five years in a garage—and string lights deserve similar respect for their material limits. Apply the storage Do’s and Don’ts. Run annual checks. Clean contacts before seasonal use. When blinking appears, diagnose systematically—not frantically. And when repair no longer makes engineering or economic sense, choose new lights with higher-grade capacitors (look for “105°C rated” or “long-life” specs) and store them with intention. Your lights won’t last forever—but with informed care, their reliable service years will multiply meaningfully.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?