String lights bring warmth and charm to patios, porches, and indoor spaces—but when sections of the cord grow noticeably warm, even uncomfortably hot, they stop being decorative and start posing real safety risks. Hot spots—localized areas along the wire or near bulbs that exceed safe operating temperatures—are more than a nuisance. They indicate underlying electrical stress that can degrade insulation, accelerate component failure, and in worst cases, ignite nearby combustibles or cause painful contact burns. Understanding why these thermal anomalies occur isn’t just about troubleshooting; it’s about recognizing early warning signs before minor inefficiency becomes a fire hazard or injury risk.

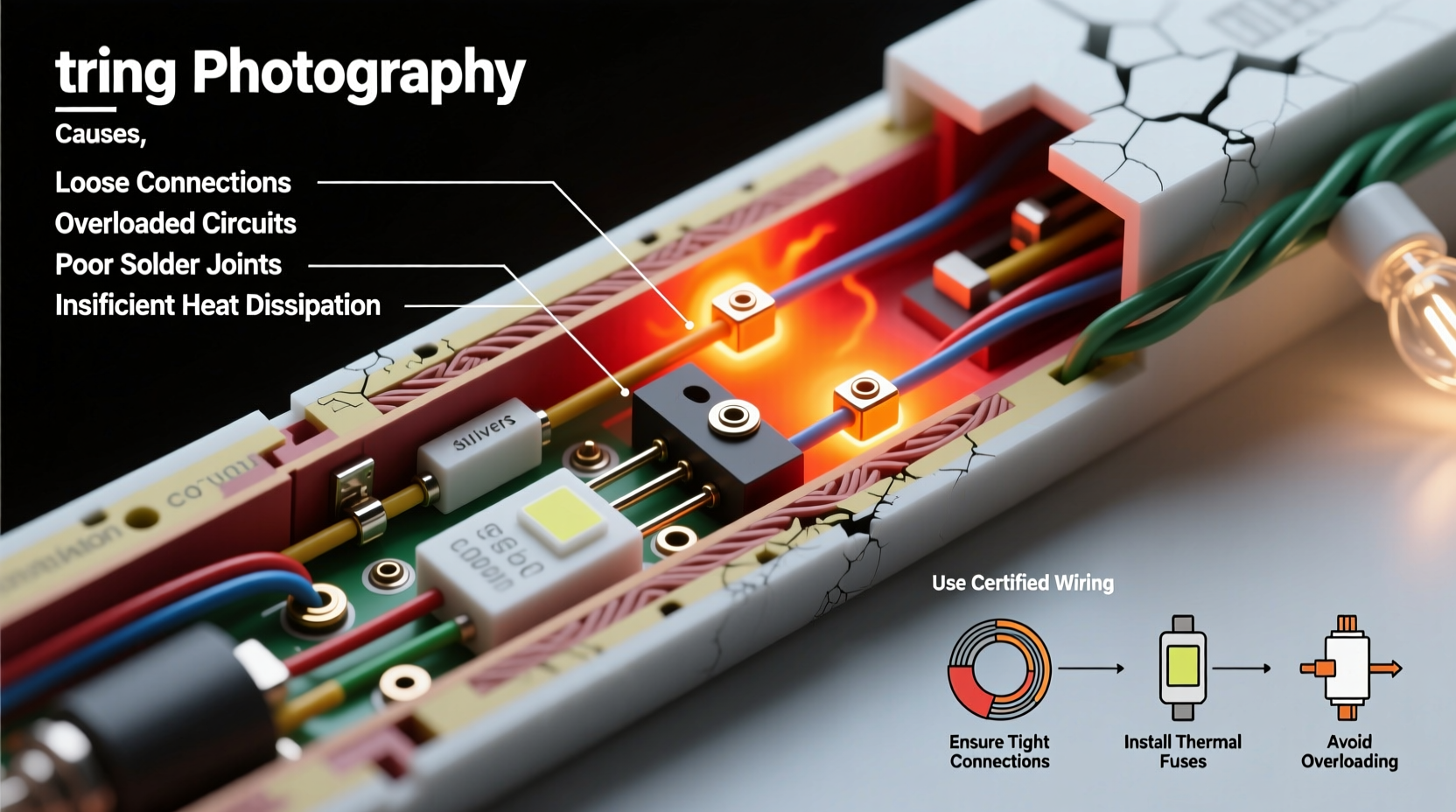

What Causes Hot Spots in String Lights?

Hot spots arise from localized increases in electrical resistance or power density. Unlike uniform heating across a well-designed circuit, hot spots concentrate energy in specific zones—often at connection points, damaged segments, or undersized conductors. Three primary mechanisms drive this phenomenon:

- Resistance buildup at connections: Loose, corroded, or oxidized splices (especially in older or outdoor-rated sets) create micro-gaps where current must arc or squeeze through reduced cross-sectional area. This dramatically raises resistance—and per Joule’s Law (P = I²R)—generates disproportionate heat.

- Wire gauge mismatch: Many budget-friendly string lights use thinner-than-spec copper or copper-clad aluminum (CCA) wire in the trunk line. When combined with high-wattage bulbs—or worse, daisy-chained extensions—the conductor overheats under sustained load, especially near the plug end where cumulative current is highest.

- Thermal trapping and ambient stress: Wrapping lights tightly around metal railings, stuffing them into enclosed eaves, or covering them with foliage restricts airflow. Heat that would normally dissipate via convection accumulates, raising surface temperatures beyond rated limits—even if the circuit itself is technically within voltage tolerance.

LED strings aren’t immune. While individual LEDs run cool, poorly regulated drivers, cheap capacitors, or overloaded parallel circuits can overheat driver boards housed inside plastic housings—particularly near the first bulb or power supply unit.

How Hot Spots Lead to Burns—and Why It’s More Common Than You Think

Burns from string lights rarely involve flames—but they do involve direct thermal injury. Skin begins to sustain first-degree burns at approximately 44°C (111°F) after prolonged contact; second-degree burns can occur in under 30 seconds at 52°C (126°F). Many low-cost incandescent strings operate bulb bases above 60°C (140°F) during extended use—and hot spots on wiring often exceed 70°C (158°F), especially near plugs or connectors.

Children, pets, and adults with reduced thermal sensitivity (e.g., diabetics or elderly individuals) are especially vulnerable. A 2022 incident report from the U.S. Consumer Product Safety Commission documented 17 emergency department visits linked to contact burns from decorative lighting—12 of which involved string lights with measurable hot spots exceeding 75°C. In every case, the burn occurred not at the bulb, but along the cord near a junction box or where lights were coiled beneath a patio table edge.

“Temperature rise at a single compromised connection can be 3–5× higher than elsewhere on the same string—even if the rest feels cool to touch. That’s why ‘feeling fine’ isn’t a safety test.” — Dr. Lena Torres, Electrical Safety Engineer, UL Solutions

Prevention Strategies: From Selection to Daily Use

Preventing hot spots starts long before you plug in the lights. It requires deliberate choices at purchase, installation, and operation—each layer reinforcing the next.

Choosing Safer String Lights

Not all lights are built to manage thermal load equally. Prioritize these features:

- Copper-only wiring: Reject any set labeled “CCA” (copper-clad aluminum)—aluminum’s higher resistivity and brittleness increase hotspot risk by up to 40% under load testing (per IEEE Std 1530-2021).

- UL or ETL listing with “wet location” certification: These undergo accelerated thermal cycling tests—exposed to 85°C air for 168 hours while energized—to verify insulation integrity and connector stability.

- Individual bulb shunts (for incandescent): Prevents full-string failure—and dangerous current surges—when one bulb burns out. Non-shunted sets force remaining bulbs to draw excess voltage, accelerating heat buildup.

- Driver-integrated LED designs: Prefer strings with constant-current drivers embedded near the plug rather than simple resistor-based drops. Drivers maintain stable current despite voltage fluctuations, reducing thermal variance.

Safe Installation Practices

Even premium lights fail if installed incorrectly. Follow these non-negotiable rules:

- Never coil excess cord tightly—loosely loop and secure with fabric ties (not metal clips or zip-ties that pinch insulation).

- Maintain at least 10 cm (4 inches) of clearance between lights and any surface—wood railings, vinyl siding, curtains, or dry vegetation.

- Avoid running cords under rugs, carpets, or furniture where airflow is zero and foot traffic adds mechanical stress.

- When using extension cords, match gauge and rating: 16 AWG for up to 25 ft, 14 AWG for 25–50 ft, and never exceed 50 ft total run (light + extension).

Do’s and Don’ts: A Thermal Safety Checklist

| Action | Do | Don’t |

|---|---|---|

| Before first use | Inspect every connector for discoloration, warping, or residue; test continuity with a multimeter if suspicious. | Plug in and walk away—run lights unattended for at least 15 minutes while monitoring temperature with an infrared thermometer (aim for <50°C on cord, <65°C on plug). |

| Daily/seasonal use | Unplug and let cool fully before storing; store loosely coiled in ventilated bins—not sealed plastic totes. | Leave lights on overnight or while sleeping; limit continuous operation to ≤8 hours unless explicitly rated for 24/7 duty. |

| Troubleshooting heat | Use a non-contact IR thermometer to map temperatures: note >10°C difference between adjacent 6-inch segments as a red flag. | Apply tape, glue, or heat-shrink over hot spots—this traps heat and masks worsening conditions. |

Real-World Example: The Patio Overload Incident

In late October 2023, a homeowner in Portland, Oregon, strung three 100-light incandescent sets along a cedar pergola—daisy-chained via two 50-ft 16 AWG extension cords. After four hours of use, her 5-year-old son touched the cord near the second set’s male plug and recoiled with a blistered palm. An electrician’s inspection revealed:

- The first extension cord’s female end had melted internal contacts (visible blackening), raising resistance by 300%.

- The second string’s plug housing was cracked, exposing bare wire strands that arced intermittently—generating micro-sparks and 82°C surface readings.

- All three sets used CCA wire and lacked shunt technology—causing cascading voltage spikes when bulbs failed.

The family replaced everything with UL-listed, copper-wire LED strings featuring integrated drivers and segmented fusing. They now follow a strict “15-minute thermal check” protocol for new installations—and keep an IR thermometer in their utility drawer. No further incidents have occurred.

Step-by-Step: How to Audit Your String Lights for Hot Spot Risk

Conduct this 12-minute audit before each season—or after any visible damage, moisture exposure, or performance change.

- Gather tools: Non-contact infrared thermometer (budget models work), magnifying glass, multimeter (optional), clean dry cloth.

- Visual sweep: Examine every plug, socket, and connector for discoloration (yellow/brown tint), warping, cracks, or white powdery corrosion (a sign of aluminum oxidation).

- Cord inspection: Run fingers gently along the entire length—feel for lumps, stiffness, or tackiness (indicating degraded insulation). Note any kinks or crushed sections.

- Power-on test: Plug in and wait 10 minutes. Scan with IR thermometer: record readings at plug, first bulb, midpoint, and last bulb. Safe thresholds: ≤50°C on cord, ≤60°C on plug body, ≤70°C on bulb base (incandescent), ≤45°C on LED driver housing.

- Load verification: Check label wattage. Total load must be ≤80% of outlet circuit capacity (e.g., max 1,440W on a standard 15A/120V circuit). Subtract other loads on same breaker.

- Action decision: If any reading exceeds safe thresholds or visual defects exist: unplug permanently and discard. Do not repair—replacement is safer and more cost-effective than risk mitigation.

FAQ: Addressing Common Concerns

Can LED string lights still cause burns?

Yes—though less frequently than incandescent. Poorly engineered LED strings may overdrive chips or overload driver components, causing localized heating in the first few inches of cord or at the plug. High-density LED strips (e.g., 60+ LEDs/meter) also generate significant heat if installed without thermal backing or airflow. Always verify thermal derating specs.

Is it safe to cover string lights with fabric or netting?

No—unless the material is explicitly rated for “direct contact with Class 2 low-voltage lighting” and tested for flame spread (ASTM E84 Class A). Standard burlap, tulle, or cotton netting acts as thermal insulation and ignition fuel. Even LED sets can reach 60°C+ at drivers—enough to scorch untreated textiles.

Why does only one section of my string feel hot?

This almost always indicates a fault: a failing bulb socket, damaged wire strand, or loose crimp in that segment. Current concentrates at the point of highest resistance, generating disproportionate heat. It is not normal—even in older sets. Isolate and replace that section, or retire the entire string.

Conclusion: Prioritize Thermal Intelligence Over Convenience

Hot spots in string lights aren’t random quirks—they’re measurable symptoms of electrical imbalance, material compromise, or operational misuse. Ignoring them trades momentary ambiance for tangible risk: burns that require medical care, damaged property, or worse. But prevention doesn’t demand expertise—just intentionality. Choose copper-wire, UL-certified lights. Install with airflow and clearance in mind. Audit temperatures before seasonal use. And remember: no decoration is worth a preventable injury. Your vigilance today protects hands, homes, and holidays tomorrow.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?