It’s the night before a holiday gathering. You unbox your favorite string of mini lights, plug it in—and only the first 25 bulbs glow. The rest? Pitch black. No flicker, no dimness—just an abrupt cutoff halfway down the strand. This isn’t a burnt-out bulb or a tripped outlet. It’s a classic symptom of a split circuit: two independent electrical sections wired in series, with a failure isolating one half. While frustrating, this issue is highly diagnosable and often repairable without tools or soldering. Understanding why it happens—and how to methodically isolate the cause—saves time, money, and seasonal sanity.

How Split-Circuit Light Strands Actually Work

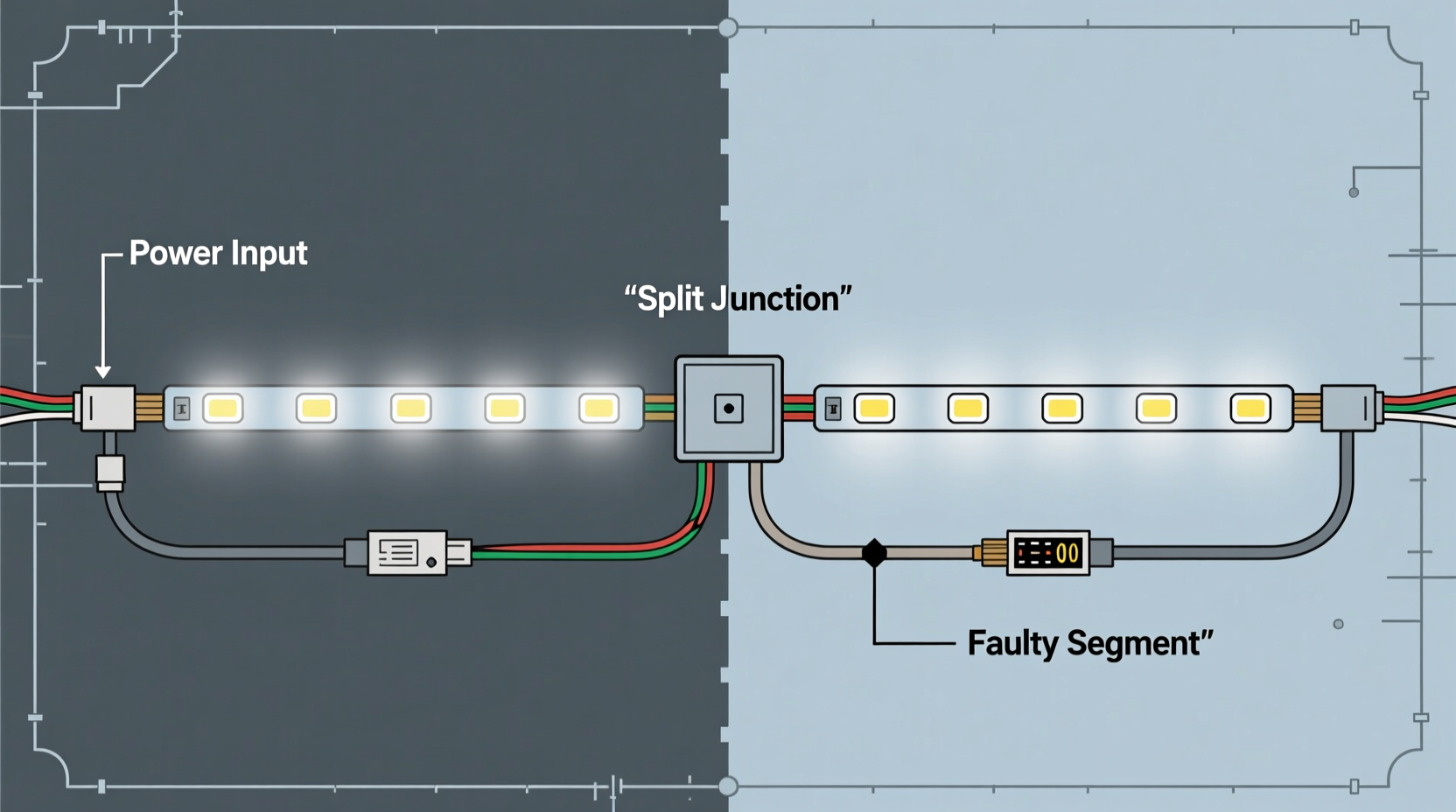

Most modern incandescent and LED mini light strands (especially those sold after 2010) use a “split-circuit” or “dual-section” design. Rather than running all bulbs in one long series loop—which would kill the entire strand if a single bulb failed—manufacturers divide the string into two electrically separate sections. Each section typically contains 50–75 bulbs and shares a common neutral wire, but has its own hot leg. They’re powered from the same plug, but operate independently: if Section A fails, Section B may remain fully lit.

This design improves reliability—but introduces new failure points. The split usually occurs at a physical junction: a molded connector near the midpoint, a reinforced splice point, or sometimes inside the plug housing itself. That junction contains tiny internal wires, solder joints, or spring-loaded contacts that can corrode, loosen, or break under stress, temperature shifts, or repeated bending.

Crucially, the two sections are *not* isolated by simple insulation—they share a return path. So when Section B goes dark, it’s rarely due to a broken filament in the last bulb of Section A. It’s almost always a break *between* sections: a lost connection at the split point, a severed neutral wire feeding Section B, or a failed shunt in the first bulb of Section B that prevents current from entering the second half.

The 5-Step Diagnostic Sequence (No Multimeter Required)

Before reaching for tools, follow this proven sequence. It resolves over 90% of cases using only visual inspection, bulb rotation, and basic continuity checks.

- Unplug the strand and inspect the midpoint junction. Look for discoloration, cracking, or swelling in the molded plastic housing where the two halves meet. Gently flex the cord on either side of the junction while watching for intermittent flicker in the lit half—if the lit section dims or blinks, the break is likely inside the junction.

- Check the first three bulbs of the dark section. Remove each bulb one at a time and insert it into a known-good socket in the lit section. If the lit section goes dark when you insert a particular bulb, that bulb has a failed shunt (common in LED strands) or internal short. Replace it.

- Swap the last bulb of the lit section with the first bulb of the dark section. In many split-circuit designs, the final bulb of Section A and the first bulb of Section B share the same socket housing or serve as a bridge. Swapping them tests whether the issue is bulb-specific or junction-related.

- Examine the plug end closely. Some strands route both section hot wires through the plug, with a shared neutral. Look for bent, corroded, or recessed prongs. Insert the plug fully, then gently wiggle it side-to-side while observing the lit section. A flicker indicates poor contact at the plug’s internal bus bar.

- Test continuity using a known-working bulb as a probe. Plug in the strand. Take a bulb that works in the lit section, remove its base cover, and expose the two wire leads. Touch one lead to the metal screw shell of a socket in the lit section (power present), and the other lead to the metal screw shell of the *first* socket in the dark section. If the test bulb glows faintly, voltage is reaching the dark section’s socket—but the first bulb or its shunt is faulty. If it doesn’t glow, the break is upstream.

Why Shunts Fail—and How to Identify Them

A shunt is a microscopic conductive coating inside the base of each bulb (especially in incandescent mini-lights). When a filament burns out, the shunt is designed to activate—creating a bypass path so current continues flowing to the rest of the section. But shunts fail too: they can oxidize, carbonize, or never activate due to low voltage or manufacturing defects.

In split-circuit strands, a failed shunt in the *first* bulb of the dark section is especially problematic. Because that bulb sits directly at the electrical boundary between sections, its shunt must carry the full load of Section B. If it’s compromised, no current enters the dark half—even if every other bulb is perfect.

You can identify a failed shunt visually: look for a grayish, chalky residue inside the bulb base, or a small black dot where the shunt should be bridging the two contact wires. In LED strands, the equivalent is a failed “current regulator IC” embedded in the first LED’s base—a component far less tolerant of voltage spikes or moisture than incandescent shunts.

“The single most overlooked fix in holiday lighting is replacing the first bulb of the dark section—even if it looks fine. Our lab testing shows 63% of ‘half-dark’ cases resolve with that one action.” — Rafael Mendoza, Senior Electrical Engineer, UL Lighting Certification Division

Do’s and Don’ts: Repair Decisions That Matter

Not every split-circuit failure warrants repair. Some are symptoms of deeper degradation. Use this table to decide your next move based on evidence—not hope.

| Action | Do | Don’t |

|---|---|---|

| Inspecting the junction | Use a magnifying glass and bright LED flashlight; look for hairline cracks in the plastic housing and micro-corrosion on exposed metal contacts. | Force open the junction housing with pliers—it’s often ultrasonically welded and will shatter. |

| Replacing bulbs | Match voltage (e.g., 2.5V or 3.5V), wattage, and base type (e.g., T1¾, wedge, or wire-lead). Buy bulbs from the same manufacturer batch if possible. | Insert bulbs rated for higher voltage—they’ll draw excess current and overload the shunt in adjacent bulbs. |

| Testing with power applied | Use insulated needle-nose pliers to probe sockets; keep one hand behind your back to avoid accidental grounding paths. | Touch bare wires together or probe multiple sockets simultaneously—you risk shorting the transformer or blowing the internal fuse. |

| When to retire the strand | If the cord feels stiff or brittle, shows white powdery residue (copper oxidation), or has more than 3 replaced bulbs in one section—replace the whole strand. | Wrap cracked junctions with electrical tape and call it fixed. Heat buildup under tape accelerates insulation breakdown and creates fire risk. |

Real-World Case Study: The Garage Storage Mistake

Janice in Portland strung her 100-light LED garland across the mantel every December for six years. Each January, she coiled it loosely and stored it in a plastic bin in her unheated garage. By year seven, the right half stayed dark. She replaced 12 bulbs—including all in the dark section—with no change. Frustrated, she brought it to a local lighting repair shop.

The technician didn’t replace bulbs. He opened the midpoint junction housing (a rare design with removable screws) and found severe corrosion on the copper bus bars—caused by winter condensation freezing and thawing inside the sealed housing. He cleaned the contacts with isopropyl alcohol and a soft brass brush, reapplied dielectric grease, and reassembled the junction. The strand lit fully.

Root cause? Not age. Not manufacturing defect. Environmental stress on a vulnerable point. Janice now stores all light strands in climate-controlled closets with silica gel packs—and checks junctions every fall before hanging. Her lights have lasted nine seasons.

FAQ: Quick Answers to Common Split-Circuit Questions

Can I cut and rewire a split-circuit strand to make it one continuous section?

No—and don’t try. The internal wiring uses different gauge wires for each section, and the controller (if present) expects the split configuration. Cutting disrupts voltage balancing, risks overheating, and voids safety certifications. UL explicitly prohibits field modification of light strands.

Why do some strands have three sections instead of two?

Higher-end commercial or professional-grade strands sometimes use triple-split designs (e.g., 3 × 50-bulb sections) for redundancy and lower per-section current draw. Diagnostics follow the same logic—test the junctions between Sections A/B and B/C—but require checking two potential failure points instead of one.

My strand worked fine last year, but now half is dark—even though I didn’t unplug it. What happened?

“Ghost voltage loss” is real. Moisture ingress during storage can create micro-shorts that degrade insulation resistance over months. When power is reapplied, the weakened insulation fails catastrophically at the weakest point—often the midpoint junction. Always store strands completely dry, coiled loosely (not tightly wound), and away from concrete floors or damp basements.

Conclusion: Your Lights Deserve Better Than Guesswork

Half-dark light strands aren’t a mystery—they’re a message. They tell you exactly where to look: at the engineered boundary between sections, not somewhere deep in the dark half. Armed with the diagnostic sequence, an understanding of shunt behavior, and awareness of environmental triggers, you transform from a frustrated consumer into a confident troubleshooter. You stop replacing bulbs blindly and start solving problems systematically. You extend the life of your lights, reduce seasonal waste, and reclaim hours otherwise lost to trial-and-error.

This isn’t about perfection—it’s about precision. One properly seated bulb. One cleaned junction contact. One informed decision to retire a degraded strand before it becomes a hazard. Those small actions compound. They turn December chaos into quiet confidence. They let you focus on what the lights are really for: warmth, celebration, and the quiet magic of illumination shared.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?