Every holiday season, the frustration repeats: you plug in your favorite string of Christmas lights, only to find that half the strand remains stubbornly dark. The bulbs look intact, the outlet works, and yet—only one section glows. This is not magic or bad luck. It’s physics. Most traditional incandescent Christmas light strings are wired in a series circuit, a design that makes them vulnerable to single-point failures. Understanding why this happens—and how to fix it—can save time, money, and seasonal cheer.

Unlike modern LED strands that often use parallel wiring or shunted bulbs, older or budget-friendly light sets rely on a continuous electrical path. When one bulb fails or becomes loose, the entire circuit breaks, cutting power to all downstream bulbs. Because these strings are typically split into two independent circuits—one for each half—the result is exactly what you see: one side lit, the other dark.

How Series Circuits Work in Christmas Lights

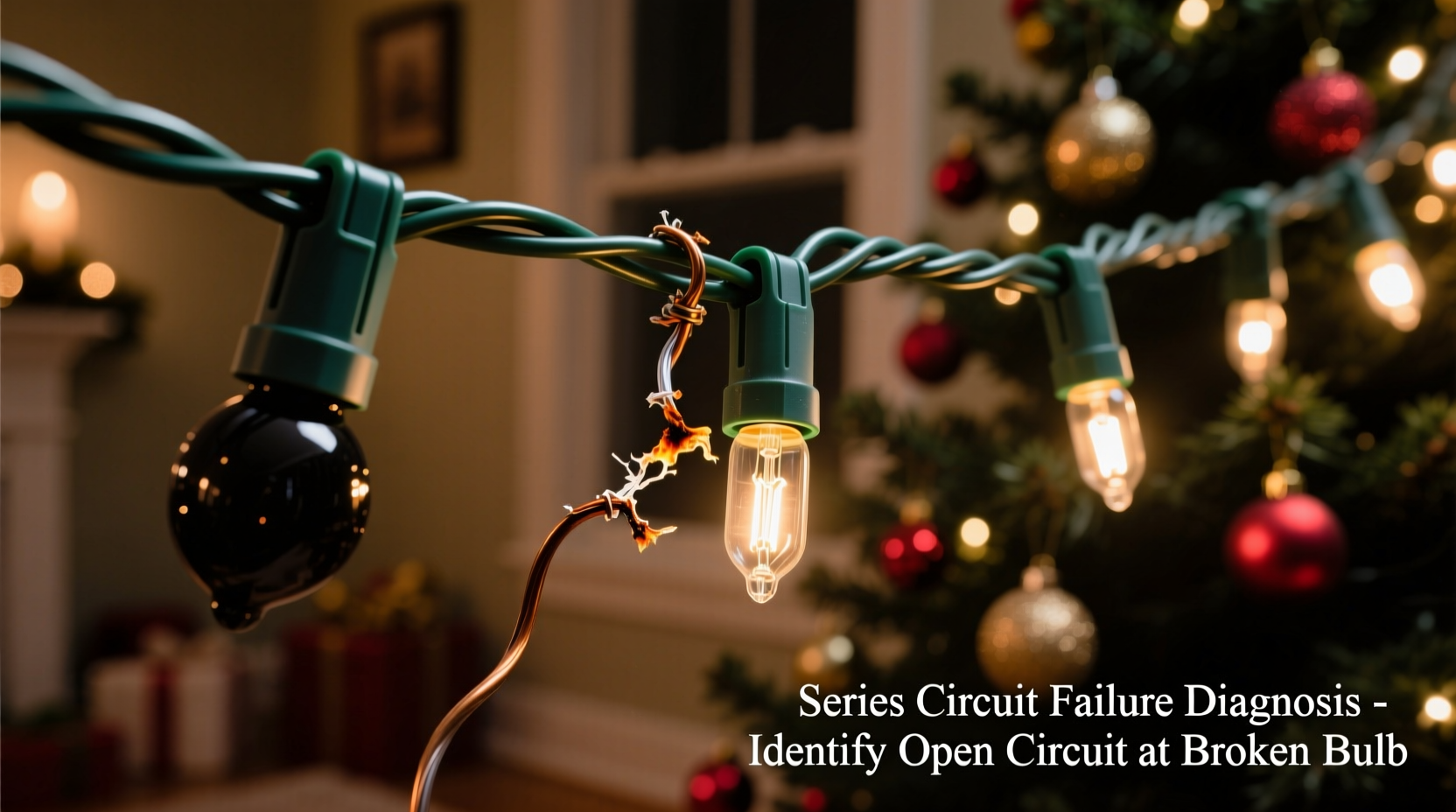

In a series circuit, electricity flows through each component in sequence. Each bulb acts as both a resistor and a conductor. Current enters the first bulb, passes through its filament, then moves to the next, and so on until it reaches the end of the strand and returns via the neutral wire. If any single point in that chain fails—whether from a burnt filament, poor contact, or corrosion—the current stops flowing beyond that point.

This explains why only half the string goes dark. Many multi-light strands are divided into two separate series circuits, each containing roughly half the total bulbs. This dual-circuit design allows manufacturers to use lower-voltage bulbs (e.g., 2.5 volts each) while still connecting the full string to standard 120-volt household power. For example, a 50-bulb strand might have two series circuits of 25 bulbs each, with each bulb rated at about 2.4 volts (25 × 2.4 = 60V per circuit; two in series across line voltage).

“Series-wired lights are cost-effective but fragile by design. One failed bulb can take out an entire segment.” — Dr. Alan Reeves, Electrical Systems Engineer, MIT Lincoln Lab

The division into two halves means that if one circuit fails, the other can still function—giving the illusion of partial operation. But diagnosing which bulb caused the break requires more than guesswork.

Common Causes of Half-Lit Light Strings

Several issues can interrupt a series circuit. Identifying the root cause is essential before attempting repairs.

- Burnt-out bulb: The most frequent culprit. When a filament burns through, the circuit opens. Even if the glass appears intact, the internal break stops current flow.

- Loose bulb: Vibration during storage or installation can cause bulbs to shift slightly in their sockets, breaking electrical contact.

- Corroded or dirty socket: Moisture exposure over time leads to oxidation inside the socket, increasing resistance or blocking conductivity.

- Frayed or damaged wire: Physical stress or rodent activity may sever internal conductors, especially near plugs or connectors.

- Shunt failure (in non-shunted bulbs): Some bulbs include a “shunt” designed to activate when the filament fails, maintaining continuity. If the bulb lacks a shunt or it doesn’t engage, the circuit breaks.

Step-by-Step Guide to Diagnose and Repair a Faulty Strand

Fixing a half-lit light string involves systematic inspection and testing. Follow this timeline to restore full illumination:

- Unplug the lights and lay them out on a flat surface where all bulbs are visible.

- Inspect visually for obvious damage: cracked bulbs, bent bases, frayed wires, or corroded sockets.

- Check the fuse compartment (usually located in the plug). Use a multimeter to test continuity or replace with identical-rated fuses (typically 3A or 5A).

- Test each bulb in the dark half using a known-working bulb from the lit side. Start near the middle of the dark section to reduce troubleshooting time (binary search method).

- Wiggle each bulb gently while the strand is plugged in (with caution) to see if flickering occurs—indicating loose connection.

- Clean corroded sockets with a cotton swab dipped in isopropyl alcohol. Let dry completely before reinserting bulbs.

- Replace suspect bulbs one at a time with new ones of matching voltage and base type (e.g., E12 candelabra).

- Reconnect and test after each replacement to confirm restoration of the circuit.

If no individual bulb resolves the issue, consider a broken wire within the strand. To locate hidden breaks:

- Use a non-contact voltage tester along the wire leading into the dark section. Loss of signal indicates a cut conductor.

- Alternatively, use a multimeter in continuity mode, probing from known good points back toward the source.

Tips for Preventing Future Failures

Maintenance and proper handling go a long way in extending the life of series-wired light strings.

- Handle by the cord, not the bulbs: Pulling on bulbs can loosen them or damage sockets.

- Label repaired sections: Mark bulbs that were recently replaced—they’re more likely to fail again soon.

- Avoid outdoor exposure without rating: Only use weatherproof-rated strands outside, and ensure connections are elevated off wet surfaces.

- Use a surge protector: Power spikes during winter storms can prematurely degrade filaments.

Comparison: Series vs. Parallel Wiring in Holiday Lights

| Feature | Series Circuit Lights | Parallel Circuit / Modern LED Lights |

|---|---|---|

| Voltage per Bulb | Low (e.g., 2–3V) | Higher (often 120V compatible) |

| Failure Impact | One bulb kills entire segment | Other bulbs stay lit |

| Shunt Reliance | High (if present) | Not required |

| Repair Difficulty | Moderate to high | Low (often modular) |

| Lifespan | Shorter due to cascade failure | Longer, especially LEDs |

| Energy Efficiency | Poor (incandescent) | High (LED variants) |

While series-wired incandescent strings remain popular due to low upfront cost, they demand more maintenance. Upgrading to parallel-wired or commercial-grade LED strands reduces long-term hassle.

Mini Case Study: Rescuing Grandma’s Heirloom Lights

Martha, a homeowner in Vermont, brought out her mother’s vintage Christmas lights every year—50 clear incandescent bulbs strung on red wire. Last season, only the first 25 lit up. She tried replacing random bulbs without success. Frustrated, she nearly discarded them—until her nephew suggested a structured approach.

He began by checking the fuses (both intact), then used a working bulb from another strand to test each socket in the dark half. At position #13 in the second circuit, inserting the known-good bulb restored the entire remaining section. The original bulb looked fine, but internally, the shunt had failed to bridge the broken filament. A $4 replacement pack fixed the problem, and the lights returned to full glory.

The experience taught Martha to inspect systematically—not emotionally. Now she tests all bulbs before storing and keeps spares labeled by year and model.

Expert Checklist: Fixing Half-Out Christmas Light Strings

- ✅ Unplug the light string

- ✅ Locate and inspect fuses in the plug

- ✅ Visually scan for damaged bulbs, wires, or sockets

- ✅ Test continuity with a multimeter or known-working bulb

- ✅ Replace suspect bulbs starting from the center of the dark section

- ✅ Clean oxidized contacts with alcohol

- ✅ Re-test after each change

- ✅ Store properly after repair

Frequently Asked Questions

Can I convert a series-wired light string to parallel?

Technically possible but impractical. Rewiring dozens of low-voltage bulbs in parallel would require extensive modification, custom voltage regulation, and loss of original aesthetics. It's more efficient to purchase a new parallel/LED strand.

Why do some bulbs burn out faster than others?

Bulbs near the beginning of the circuit draw slightly higher current due to voltage drop characteristics in series wiring. Additionally, physical placement (e.g., near heat sources or bends in the wire) can accelerate wear. Manufacturing variances also play a role.

Are there tools that make finding dead bulbs easier?

Yes. Devices like the \"LightKeeper Pro\" send pulses through the strand to trigger shunts or detect open circuits without removing bulbs. These are especially useful for mini-lights with hard-to-access bases.

Conclusion: Keep the Lights On with Smart Troubleshooting

A half-dark Christmas light string isn't a lost cause—it's a solvable electrical puzzle. By understanding the behavior of series circuits, recognizing common failure modes, and applying methodical diagnostics, you can revive even aging strands. Whether preserving sentimental decorations or maximizing seasonal budgets, the ability to repair rather than replace adds real value.

Modern lighting technology continues to evolve toward greater reliability, but millions of series-wired sets remain in use. Knowing how they work empowers you to extend their service life, reduce waste, and maintain tradition without compromise.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?