There’s nothing more disappointing than opening your bread machine to find a beautifully risen loaf that suddenly sinks in the center. The dome you were hoping for has caved in, leaving behind a dense, uneven crumb and a sense of culinary defeat. While this issue is frustratingly common, it's rarely due to a single cause. Instead, it's often the result of subtle imbalances in ingredients, timing, temperature, or machine function. Understanding why your bread collapses—and how to fix it—can transform your baking from inconsistent to reliable.

Bread machine baking simplifies the process, but it doesn’t eliminate the science behind fermentation, gluten development, and oven spring. When any part of that system fails, especially during the final rise or bake phase, the structure can't support itself. This article dives deep into the root causes of collapsed loaves, offers practical fixes, and equips you with a clear action plan to achieve consistently well-risen bread.

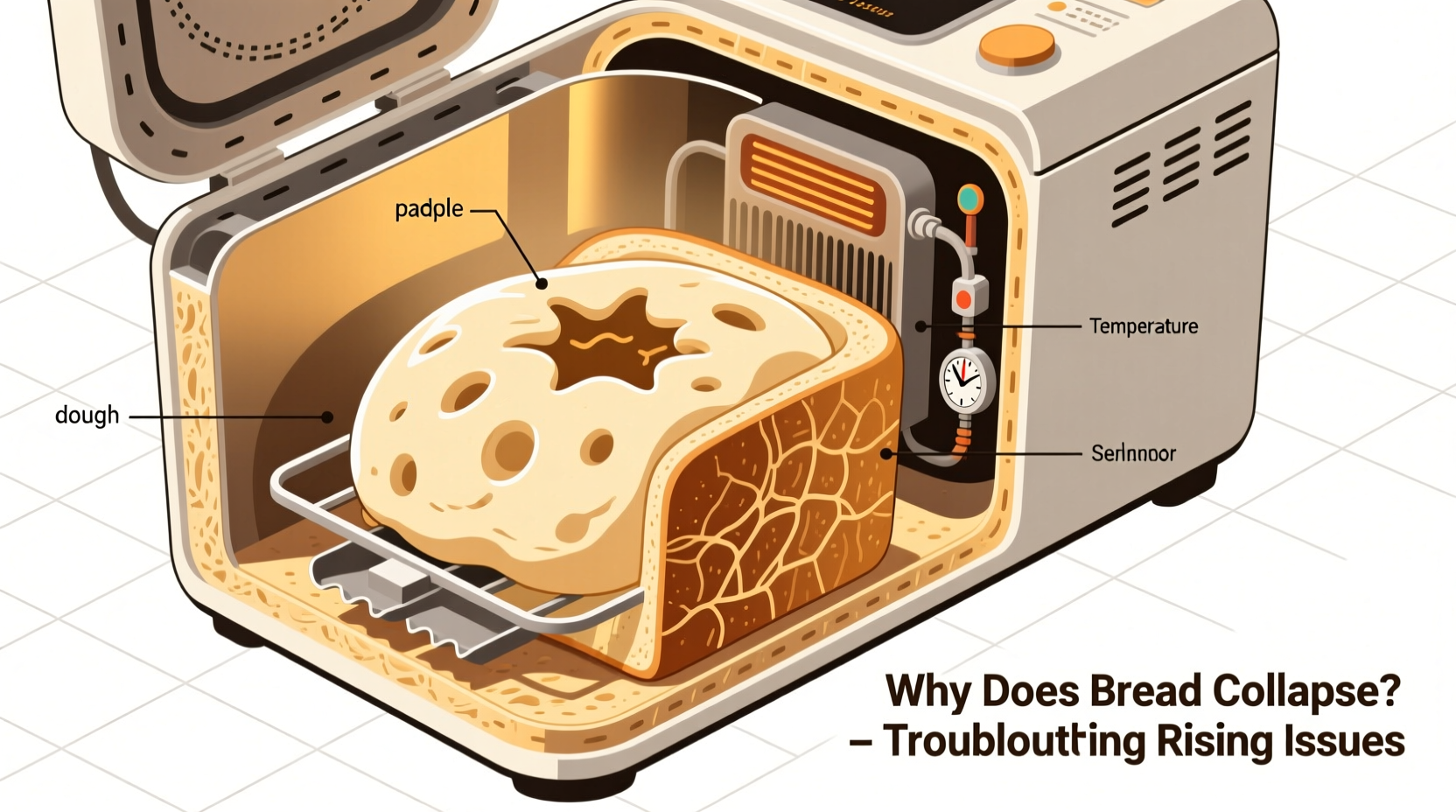

Understanding the Collapse: What Happens During Baking?

A collapsing loaf typically occurs when the internal structure of the bread cannot sustain its volume after rising. In a bread machine, the dough goes through mixing, rising, proofing, and baking—all automated. If the gluten network is weak, gas retention is poor, or the oven heat isn’t sufficient to set the crust quickly enough, the loaf may over-expand and then fall.

The most vulnerable stage is the transition from the final proof to the early baking phase. As heat increases, yeast becomes hyperactive (a phenomenon called \"oven spring\"), producing a last burst of carbon dioxide. But if the dough lacks strength or the crust forms too slowly, the expanding gases push outward without structural support, causing the center to cave in.

This isn’t always a sign of failure—it can be corrected. By identifying whether the problem lies in ingredients, technique, or machine settings, you can adjust accordingly.

Common Causes of Bread Machine Loaf Collapse

Several factors contribute to a sunken middle. Most fall into one of five categories: ingredient imbalance, moisture issues, yeast problems, incorrect settings, or mechanical faults.

1. Too Much Liquid or Too Little Flour

Dough that’s too wet lacks the structural integrity to hold its shape. Excess moisture prevents gluten strands from forming a strong network, leading to poor gas retention. Even a few extra tablespoons of water can make a difference, especially in high-hydration recipes designed for hand shaping, not machine cycles.

2. Overuse of Yeast or Sugar

Too much yeast accelerates fermentation, creating excessive gas before the gluten is ready to contain it. Similarly, high sugar content feeds yeast aggressively, causing rapid expansion followed by collapse. Sweet bread cycles account for this, but using regular settings for enriched doughs can backfire.

3. Old or Improperly Stored Yeast

Fresh yeast is essential. If your yeast is past its expiration date, exposed to moisture, or stored in warm conditions, its leavening power diminishes. Weak yeast leads to incomplete rising early on, so the machine compensates by extending rise times—only to fail later when the dough overproofs.

4. Incorrect Cycle Selection

Using a light crust setting for a heavy whole grain loaf, or selecting “rapid rise” for a dense recipe, disrupts timing. Rapid cycles shorten rest periods, which may not allow proper gluten development. Whole grain flours absorb liquid more slowly; skipping a longer soak phase can result in weak structure.

5. Bread Pan or Kneading Paddle Issues

If the kneading blade isn’t properly seated or becomes dislodged, mixing is uneven. Dough may appear lumpy or under-kneaded, leading to inconsistent texture. Also, older machines may have worn motors that don’t generate enough torque for proper gluten development.

“Consistency in ingredient measurement and cycle selection accounts for 80% of successful bread machine outcomes.” — Dr. Laura Simmons, Food Scientist & Baking Technologist

Troubleshooting Checklist: Step-by-Step Fixes

Follow this systematic approach to identify and correct the cause of your collapsing loaf.

- Verify ingredient freshness: Test yeast by dissolving 1 tsp in ¼ cup warm water with ½ tsp sugar. It should foam within 5–10 minutes.

- Check flour type: Use bread flour for better gluten formation. Avoid cake or pastry flour unless specified.

- Adjust liquid ratio: Reduce water by 1–2 tbsp, especially in humid climates where flour absorbs less moisture.

- Weigh ingredients: Volume measurements vary; use a kitchen scale for accuracy (e.g., 1 cup all-purpose flour = ~120g).

- Select the correct cycle: Match the setting to the flour and recipe type (e.g., whole wheat, sourdough, basic, sweet).

- Inspect the kneading paddle: Ensure it’s securely attached and rotating freely.

- Clean the heating element: Residue buildup can cause uneven baking. Wipe with a damp cloth when cool.

- Avoid opening the lid: Heat loss during the rise or bake phase can stall yeast activity and weaken structure.

Do’s and Don’ts: Ingredient and Technique Guide

| Action | Do | Don’t |

|---|---|---|

| Liquid Addition | Add water gradually; start with ¾ of the amount and adjust. | Pour all liquid at once without checking consistency. |

| Flour Use | Use bread flour or add 1 tbsp vital wheat gluten per cup. | Substitute self-rising flour or low-protein alternatives. |

| Yeast Handling | Store in the freezer; use within 4 months of opening. | Keep near the stove or in a humid cabinet. |

| Salt Placement | Place salt in a separate corner from yeast to prevent early deactivation. | Mix salt directly with yeast and water. |

| Machine Maintenance | Wipe interior monthly; check paddle alignment. | Ignore residue or unusual noises during mixing. |

Real-World Example: Sarah’s Sourdough Struggles

Sarah had been using her bread machine for years with consistent results—until she switched to a homemade sourdough starter. Excited to replicate artisanal loaves, she replaced commercial yeast with ½ cup of active starter and kept the rest of the recipe unchanged. Her first few attempts rose beautifully mid-cycle, only to collapse completely by the end.

After reviewing the process, she realized two key mistakes: the added moisture from the starter wasn’t offset by reducing water, and the “basic” cycle didn’t accommodate the slower fermentation sourdough requires. She adjusted by reducing liquid by 3 tablespoons and switching to the “dough” cycle, removing the loaf to shape and bake in the oven. The result? A perfectly domed, chewy sourdough with an open crumb.

Sarah’s experience highlights a crucial point: not all recipes are machine-compatible without modification. Traditional techniques often need adaptation for automation.

How to Prevent Collapse: Proactive Measures

Prevention starts before you press “start.” These strategies help build resilient dough capable of withstanding the machine’s environment.

Increase Gluten Strength

Bread flour contains 12–14% protein, compared to 8–11% in all-purpose flour. Higher protein means more gluten, which traps gas and supports rise. For whole grain recipes, which naturally inhibit gluten development, add 1–2 teaspoons of vital wheat gluten per cup of flour.

Control Fermentation Speed

Rapid cycles compress fermentation into a short window, increasing the risk of overproofing. For richer, more stable loaves, choose longer cycles—even overnight settings. Cooler room temperatures also slow yeast activity, allowing for more even gas production.

Balance Enriching Ingredients

Eggs, butter, milk, and sugar enrich flavor and texture but can interfere with structure. Enriched doughs require stronger gluten and careful timing. Use the “sweet” or “deluxe” cycle, which adjusts rise duration and baking temperature for these ingredients.

When the Machine Might Be the Problem

Even with perfect ingredients and technique, hardware issues can sabotage results. Consider these possibilities:

- Thermostat malfunction: If the machine runs too hot, yeast dies prematurely; if too cool, proofing stalls. An infrared thermometer can check internal temperature during the bake phase (should reach 350°F–375°F).

- Heating element wear: Older models lose efficiency. Uneven browning or long bake times suggest replacement may be needed.

- Lid seal degradation: A loose or warped lid allows heat and steam to escape, disrupting oven spring.

If multiple loaves fail despite corrections, try making dough in the machine but baking it in a conventional oven. If the oven-baked version holds its shape, the issue is likely thermal regulation within the machine.

FAQ: Common Questions About Collapsing Bread Machine Loaves

Why does my bread rise and then fall before baking is complete?

This usually indicates overproofing. The yeast produced too much gas during the final rise, stretching the gluten beyond its limit. When heat hits, instead of expanding evenly, the structure collapses. To fix, reduce yeast by ¼ tsp, lower sugar, or choose a shorter rise cycle.

Can humidity affect my bread machine results?

Yes. High humidity increases moisture absorption in flour. You may need to reduce liquid by 1–2 tablespoons in summer or rainy seasons. Conversely, in dry environments, dough may need slightly more water to prevent toughness.

Is it safe to eat bread that collapsed in the middle?

Absolutely. Structural failure doesn’t compromise safety. The texture may be denser, but the bread is still edible. Use it for toast, croutons, or breadcrumbs if appearance matters.

Final Steps to Consistent Success

Fixing a collapsing loaf isn’t about luck—it’s about precision and observation. Start by standardizing your process: use the same brand of flour, measure by weight, and keep a baking journal noting adjustments and outcomes. Over time, patterns will emerge, revealing what works best for your machine and environment.

Remember, bread machines vary by model and age. What works in a Zojirushi may not translate directly to a Cuisinart. Manufacturer guidelines matter, but so does real-world testing. Small tweaks—like reducing water, switching flour, or changing cycles—often yield dramatic improvements.

“The best bread machine users aren’t those with the fanciest models—they’re the ones who learn their machine’s quirks and adapt.” — Mark Rivera, Home Appliance Technician & Baker

Conclusion

Collapsing bread in the middle isn’t a dead end—it’s feedback. Each failed loaf tells you something about balance, timing, or equipment. By systematically addressing ingredients, settings, and maintenance, you can turn frustration into mastery. Don’t settle for sunken centers or dense crumbs. Apply these insights, experiment thoughtfully, and soon you’ll pull out perfectly risen loaves with confidence.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?