Candle tunneling—when wax melts only around the wick, leaving a ring of unburned wax along the edges—is one of the most common frustrations among candle lovers. It not only shortens the life of your candle but can also make it difficult to relight and reduce fragrance throw. The good news? Tunneling is usually preventable with proper wick selection, burn techniques, and maintenance. Understanding the science behind wax behavior and flame dynamics empowers you to get the most out of every candle, whether store-bought or handmade.

The Science Behind Candle Tunneling

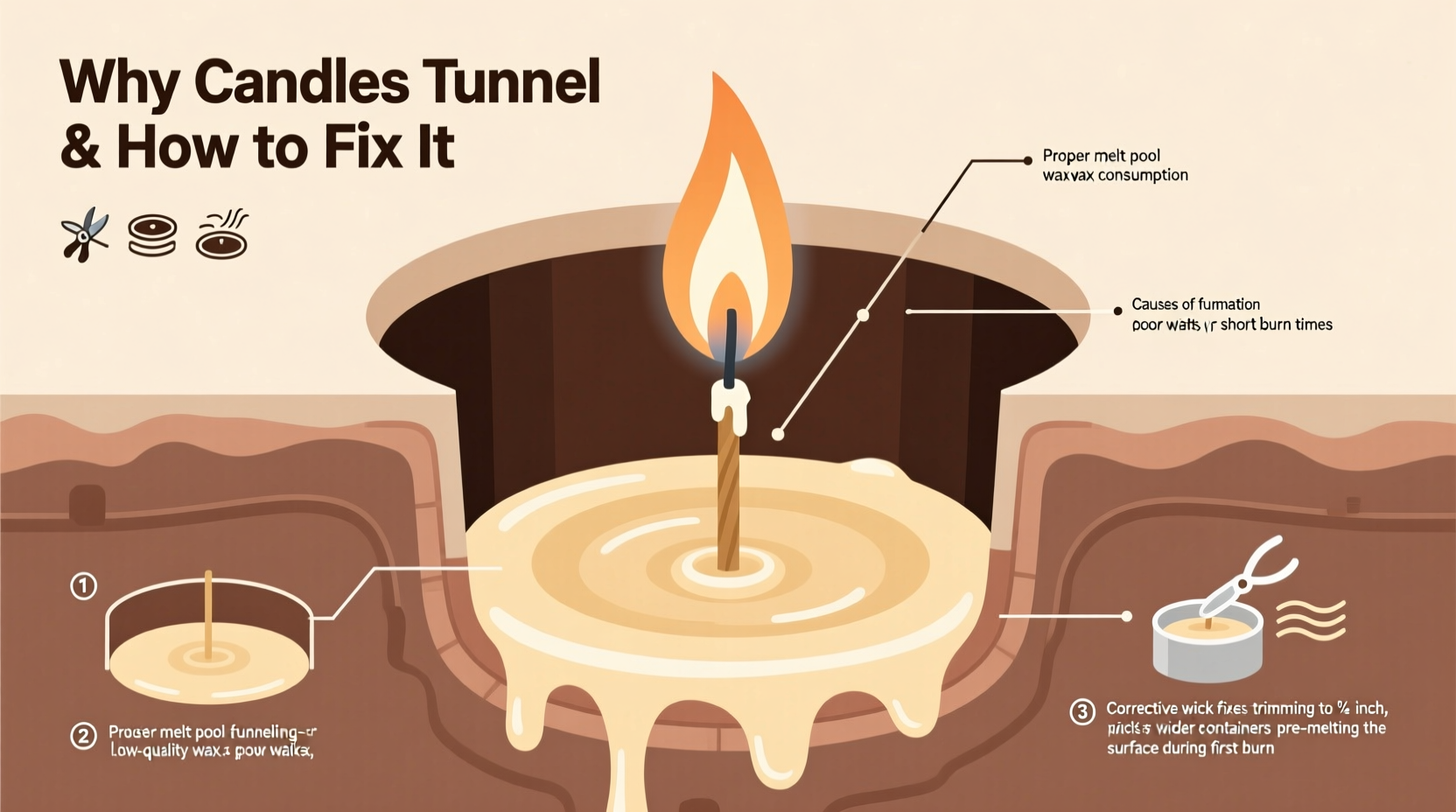

When a candle burns, heat from the flame liquefies the surrounding wax, which is then drawn up the wick via capillary action and vaporized to sustain combustion. For optimal performance, the melted wax pool should reach the container’s edge during the first burn. This process, known as \"memory setting,\" determines how the candle will burn in subsequent uses.

Tunneling occurs when the initial melt pool doesn’t extend fully across the surface. Instead, the flame consumes wax only in a narrow column directly above the wick, leaving thick walls of unmelted wax on the sides. Over time, this creates a deep well that restricts oxygen flow, drowns the wick, and diminishes scent dispersion.

The root cause often lies in mismatched wick size, improper burn duration, or suboptimal environmental conditions. A wick that’s too small won’t generate enough heat to melt the full diameter of the candle. Conversely, a wick that’s too large may flare excessively, producing soot and consuming wax too quickly—but still fail to create a full melt pool if extinguished prematurely.

Wick Selection: Matching Flame to Wax

The wick is the engine of your candle. Its job is to deliver the right amount of fuel (melted wax) to maintain a steady, clean flame. Choosing the correct wick depends on several factors: wax type, container diameter, fragrance load, and dye concentration.

Soy wax, for example, generally requires a larger wick than paraffin because it has a higher melt point and lower capillary flow. Beeswax, being dense and viscous, demands even more robust wicking. Common wick types include cotton, wood, and zinc-core. Cotton braided wicks are standard in many containers, while wooden wicks offer a soft crackle and broad flame ideal for wide jars.

If you're making candles, testing different wicks is essential. A properly sized wick produces a flame between ½ to 1 inch tall, generates a melt pool reaching the jar’s edge within 2–4 hours (depending on size), and leaves minimal soot or mushrooming at the tip.

“Wick choice isn’t one-size-fits-all. Even a ¼-inch difference in container width can require a completely different wick type.” — Daniel Reyes, Master Candle Artisan & Educator

Step-by-Step Guide to Fixing and Preventing Tunneling

Whether you’re dealing with a newly purchased candle or troubleshooting a homemade batch, follow this systematic approach to restore even burning and avoid future tunneling.

- Assess the current state: Measure the depth of the tunnel and the width of the remaining wax wall. If the well is deeper than ½ inch, intervention is needed.

- Trim the wick: Ensure the wick is between ¼ and ⅜ inch before lighting. A longer wick creates a larger, unstable flame that may carbonize without spreading heat evenly.

- Create a foil collar (for deep tunnels): Loosely wrap aluminum foil around the rim of the container, letting it drape down into the tunnel. This reflects heat inward, helping melt the stubborn outer wax.

- Burn in intervals: Light the candle and let it burn for no more than 2 hours at a time. Monitor the melt pool expansion. Repeat every few hours, removing debris from prior burns.

- Use a heat gun (optional): For severe cases, gently apply a heat gun or hair dryer to the wax walls to soften them before lighting. Never overheat glass containers.

- Rotate candles: If using multiple candles, rotate them regularly to ensure each gets sufficient burn time to set its memory correctly.

Do’s and Don’ts of Candle Maintenance

| Do’s | Don’ts |

|---|---|

| Trim the wick before every use | Leave wicks untrimmed or charred |

| Burn long enough to achieve full melt pool | Burn for less than 1 hour repeatedly |

| Store candles in cool, dark places | Expose candles to direct sunlight or heat sources |

| Use a wick dipper to extinguish flames | Blow out candles (causes smoke and splatter) |

| Clean debris from prior burns | Allow wick trimmings or dust to accumulate in wax |

Real Example: Recovering a Tunnelled Soy Candle

Jenna bought a popular soy-blend candle in a 3-inch diameter jar. Excited to use it, she lit it for just 45 minutes each evening. After four uses, she noticed a growing tunnel about 1.5 inches deep. The flame struggled to stay lit, and the scent barely filled the room.

She researched the issue and realized she hadn’t allowed a full melt pool during the first burn. Following recovery steps, she trimmed the wick, wrapped foil around the top to reflect heat inward, and burned the candle in two-hour increments. By the fifth session, the melt pool finally reached the edges. From then on, she ensured each burn lasted at least 3 hours (the recommended time for a 3-inch jar), and the candle began performing as intended—clean, even, and aromatic.

This case illustrates how small habits compound over time. Consistent attention to burn time and wick care transformed a failing candle into a reliable source of ambiance and fragrance.

Checklist: Ensuring an Even Candle Burn

- ✅ Confirm the wick is centered and straight before lighting

- ✅ Trim wick to ¼–⅜ inch before each use

- ✅ Allow 1 hour of burn time per inch of candle diameter

- ✅ Avoid drafts that cause flickering or uneven melting

- ✅ Clean the wax pool of debris between burns

- ✅ Rotate multiple candles to prevent underuse

- ✅ Store unused candles away from sunlight and temperature swings

- ✅ Use foil collars or gentle heat to correct existing tunnels

Frequently Asked Questions

Can I fix a severely tunneled candle?

Yes. Use a foil collar to contain heat and burn in two-hour sessions until the melt pool expands outward. For extreme cases, carefully remove excess wax with a spoon after softening it with a hair dryer, then resume proper burning practices.

Why do some candles tunnel even with proper wick size?

Even with correct wicking, environmental factors like cold rooms, air currents, or short burn times can prevent full melt pools. Additionally, high fragrance or dye loads can alter wax viscosity and interfere with capillary flow.

Is tunneling worse with certain waxes?

Soy wax is more prone to tunneling due to its slower melt rate and tendency to adhere tightly to glass. Paraffin tends to release more easily from containers and flows better, reducing tunnel risk. However, poor burning habits affect all wax types.

Expert Insight: Wick Dynamics and Container Design

The relationship between wick, wax, and container geometry is delicate. Wide jars require larger or multiple wicks to ensure even heating. A single small wick in a 4-inch jar will almost certainly tunnel, regardless of burn time.

“In container candles, diameter dictates wick strategy. Above 3 inches, consider double or triple wicking. Otherwise, you’re fighting physics.” — Lena Patel, Formulation Chemist & Candle Consultant

Moreover, textured or opaque containers can mask early signs of tunneling, delaying corrective action. Clear glass allows visual monitoring of wax levels and melt pool development—a subtle advantage for conscientious users.

Conclusion: Take Control of Your Candle Experience

Tunneling doesn’t have to be inevitable. With awareness of wick function, disciplined burn routines, and timely interventions, you can enjoy candles that burn cleanly, last longer, and release their fragrance fully. Whether you're a casual user or a dedicated enthusiast, applying these principles transforms candle care from guesswork into a predictable, satisfying ritual.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?