Homemade yogurt is a rewarding kitchen project—creamy, tangy, and free of additives. But nothing is more frustrating than opening your jar only to find a pool of clear liquid on top: whey. While some separation is normal, excessive or premature weeping can signal problems in your process. Understanding why this happens—and how to prevent it—is key to achieving consistently smooth, thick yogurt every time.

Whey separation, also known as syneresis, occurs when the proteins in yogurt contract and release liquid. It’s not dangerous or a sign of spoilage, but it can affect texture and appearance. More importantly, frequent separation may point to underlying issues in temperature control, incubation, milk selection, or handling. This guide breaks down the science behind whey formation, identifies common causes, and offers practical solutions to help you troubleshoot and perfect your yogurt-making routine.

Understanding Whey in Yogurt: The Science Behind Separation

Yogurt forms when lactic acid bacteria ferment lactose (milk sugar), producing lactic acid. As acidity increases, the pH drops, causing milk proteins—mainly casein—to coagulate and form a gel-like structure that traps water. This network gives yogurt its thickness. However, if the protein matrix becomes too tight or unstable, it begins to expel water, resulting in visible whey.

This process is natural to some degree. Even commercial yogurts often have a thin layer of whey, which manufacturers sometimes remove or reincorporate. In homemade batches, though, separation tends to be more pronounced due to less precise control over variables like temperature, bacterial activity, and milk composition.

The presence of whey isn’t inherently bad. In fact, whey contains valuable nutrients like protein, calcium, and B vitamins. Some people drain it off intentionally to make thicker Greek-style yogurt. The concern arises when separation happens too early, too aggressively, or inconsistently—indicating a flaw in technique.

“Yogurt texture hinges on a delicate balance of protein stability, bacterial health, and thermal precision. Small deviations can lead to significant changes in consistency.” — Dr. Lena Patel, Food Microbiologist and Dairy Fermentation Specialist

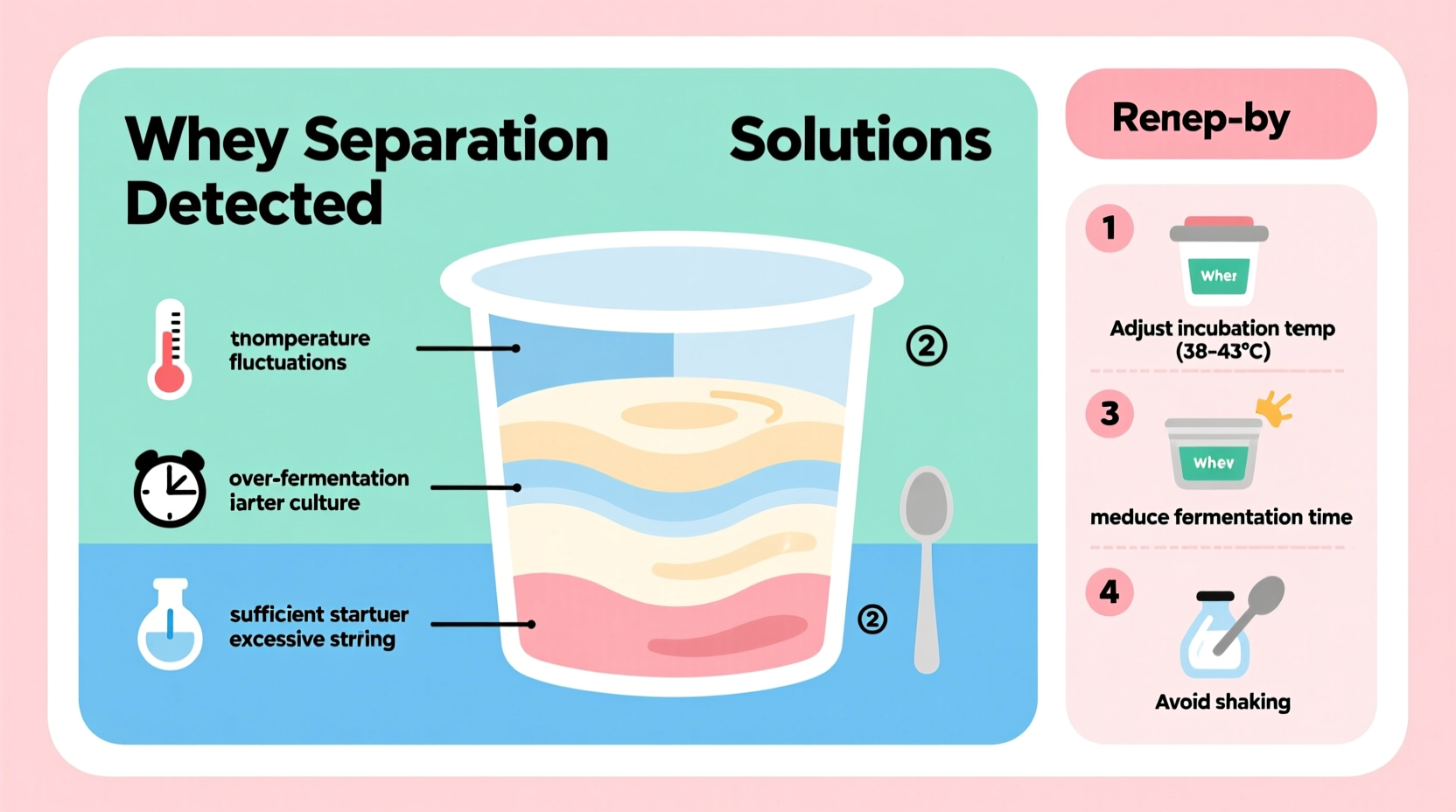

Common Causes of Excessive Whey Separation

Multiple factors influence whether your yogurt stays cohesive or breaks down prematurely. Below are the most frequent culprits behind unwanted whey formation:

1. Over-Incubation

Leaving yogurt to culture for too long increases acid production. As pH drops below 4.0, the protein network contracts excessively, squeezing out more whey. While longer incubation yields a tangier flavor, it risks over-acidification and grainy texture.

2. High Incubation Temperature

Temperatures above 115°F (46°C) stress beneficial bacteria and denature milk proteins unevenly. This weakens the gel structure, making it prone to collapse and liquid leakage during cooling or storage.

3. Rapid Cooling After Incubation

Sudden temperature changes cause thermal shock. When hot yogurt is placed directly into the refrigerator, the rapid contraction of proteins forces out trapped moisture. Gradual cooling preserves gel integrity.

4. Agitation During or After Culturing

Jostling, stirring, or moving the jars while the yogurt sets disrupts the developing protein matrix. Even gentle shaking after incubation can trigger immediate whey release.

5. Low-Protein Milk or Additives

Milk with low protein content—such as ultra-filtered or certain non-dairy alternatives—doesn’t provide enough structural foundation. Similarly, additives like carrageenan or gums in plant-based milks can interfere with proper gelation.

6. Improper Milk Heating

Failing to heat milk to at least 180°F (82°C) before cooling prevents full protein unfolding (denaturation). Properly heated proteins bond more effectively during fermentation, creating a stronger gel.

Troubleshooting Checklist: How to Prevent Whey Separation

Use this checklist to identify and correct issues in your yogurt-making process. Follow each step carefully to improve consistency and minimize syneresis.

- Heat milk properly: Bring milk to 180°F (82°C) and maintain for 10–20 minutes, stirring occasionally.

- Cool milk gradually: Allow milk to cool slowly to 110°F (43°C) before adding starter culture.

- Use fresh, active starter: Ensure your starter contains live cultures; avoid using yogurt that’s been refrigerated for over two weeks.

- Incubate at the right temperature: Maintain 108–112°F (42–44°C) for 6–8 hours. Use a yogurt maker, oven with light on, or insulated cooler.

- Avoid over-incubation: Do not exceed 10 hours unless making laban or other strongly fermented styles.

- Cool slowly: Let yogurt sit at room temperature for 1–2 hours post-incubation before refrigerating.

- Minimize disturbance: Do not shake, stir, or transport jars during culturing or initial chilling.

- Choose high-protein milk: Whole dairy milk with 3.25% fat and standard protein levels works best. Avoid ultra-pasteurized or UHT milk if possible.

- Add thickeners if needed: Incorporate dry milk powder (¼ cup per quart) or gelatin (½ tsp dissolved) for extra body.

- Strain for thickness (optional): If separation still occurs, strain through cheesecloth to make Greek-style yogurt and repurpose the whey.

Do’s and Don’ts of Homemade Yogurt Making

| Do’s | Don’ts |

|---|---|

| Heat milk to 180°F to denature proteins | Use raw milk without proper heating (risk of pathogens) |

| Cool milk slowly to 110°F before adding starter | Add starter to milk that’s too hot (>115°F), killing bacteria |

| Incubate at 108–112°F for 6–8 hours | Extend incubation beyond 10 hours unnecessarily |

| Cool yogurt gradually before refrigeration | Place hot jars directly into the fridge |

| Use glass jars with tight lids for incubation | Stir or shake yogurt during setting phase |

| Store finished yogurt in clean containers for up to 2 weeks | Use old or expired starter cultures repeatedly |

Real-World Example: Fixing a Problem Batch

Sarah had been making yogurt weekly for months, but recently noticed increasing whey separation—even within hours of refrigeration. Her process hadn’t changed: she used the same whole milk, heated it to 180°F, added a spoonful of last week’s batch as starter, and incubated in a yogurt maker for 8 hours. Yet her latest jars were pooling with liquid by day two.

After reviewing her method, Sarah realized she’d switched to a new brand of organic milk labeled “ultra-pasteurized.” Research revealed that UHT processing alters protein structure, reducing its ability to form stable gels. She also discovered her yogurt maker was running slightly hotter than advertised—closer to 118°F—which accelerated acid development.

To fix the issue, Sarah adjusted her approach: she began blending the ultra-pasteurized milk with ¼ cup of dry milk powder per quart to boost protein content and calibrated her incubator using a digital thermometer. She also reduced incubation time to 7 hours. The next batch set firmly with minimal whey, restoring her confidence in the process.

Sarah now keeps a log of milk brands and incubation temperatures, allowing her to replicate success and troubleshoot faster when inconsistencies arise.

Step-by-Step Guide to Making Whey-Stable Yogurt

Follow this detailed procedure to minimize separation and achieve reliably creamy homemade yogurt:

- Gather Equipment: Saucepan, thermometer, whisk, glass jars, incubation device (yogurt maker, oven, etc.), and starter culture.

- Heat Milk: Pour 1 quart of milk into a saucepan. Heat over medium until it reaches 180°F (82°C). Hold for 10–20 minutes, stirring occasionally to prevent scorching.

- Cool Milk: Remove from heat and cool to 110°F (43°C). Place the pot in an ice bath or let it sit undisturbed on the counter, checking every 10 minutes.

- Add Starter: Once cooled, whisk in 2 tablespoons of plain live-culture yogurt or freeze-dried starter. Mix thoroughly but gently.

- Pour into Jars: Transfer mixture into clean glass jars. Seal with lids to prevent contamination and drying.

- Incubate: Place jars in a pre-warmed yogurt maker or warm environment (e.g., oven with light on). Maintain 108–112°F for 6–8 hours. Do not disturb.

- Check Set: After 6 hours, gently tilt a jar. If the surface wrinkles and holds together, it’s done. If still liquid, continue incubating in 30-minute increments.

- Cool Gradually: Remove jars and let them sit at room temperature for 1–2 hours before refrigerating.

- Refrigerate: Chill for at least 6 hours before serving. This allows final thickening and flavor development.

- Handle Gently: When storing or serving, scoop from the top down to avoid disturbing the structure.

Frequently Asked Questions

Is whey in yogurt safe to consume?

Yes, absolutely. Whey is rich in protein, lactose, vitamins, and beneficial bacteria. Many people drink it or use it in cooking. If you prefer a thicker texture, simply stir it back in or strain it off for Greek-style yogurt.

Can I fix yogurt that has already separated?

You can partially restore texture by gently stirring the whey back in. For a thicker result, strain the yogurt through cheesecloth for 1–3 hours. Note that once broken, the gel won’t fully regain its original smoothness, but the flavor remains unaffected.

Why does my yogurt separate more after a few days in the fridge?

Slow acidification continues even under refrigeration, albeit at a much slower rate. Over time, this gradual pH drop can tighten the protein network and release small amounts of whey. This is normal. Stirring before use resolves the issue.

Conclusion: Master Your Yogurt, Minimize the Whey

Whey separation in homemade yogurt isn’t a failure—it’s feedback. Each batch teaches you something about your ingredients, equipment, and environment. By understanding the science behind protein behavior and microbial activity, you gain control over texture and consistency. Small adjustments in temperature, timing, and milk selection can transform runny, weepy yogurt into a luxuriously thick, stable product.

Don’t be discouraged by early setbacks. Even experienced home fermenters encounter occasional separation. What matters is learning from each batch and refining your method. With attention to detail and a commitment to best practices, you’ll produce yogurt that’s not only delicious but visually appealing and texturally satisfying.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?