Hollow ice cubes are more than just a cosmetic issue—they’re a sign that something in your ice maker’s operation is off. While they may look unusual, the problem often stems from mechanical, thermal, or water supply issues that can be diagnosed and corrected at home. Unlike solid cubes that chill drinks efficiently, hollow ones melt faster and weaken your beverage. Understanding the root causes not only restores performance but also extends the life of your appliance. This guide breaks down the most common reasons behind hollow ice production and provides actionable steps to resolve them.

Understanding How Ice Makers Form Cubes

Before troubleshooting, it helps to understand how an automatic ice maker functions. Most household models use a timed freezing cycle where water is dispensed into a mold, cooled until frozen, then ejected by a heated coil or mechanism. The process relies on consistent water flow, adequate freezing temperatures, and proper timing. When any part of this sequence is disrupted, the result can be incomplete freezing—leading to hollow centers.

The formation of hollow cubes typically occurs when the outer layer of water freezes quickly while the inner portion remains liquid longer. As the ejection phase begins, the still-liquid core drains out, leaving behind a shell. This is normal to some degree in fast-cycle systems, but pronounced hollowness indicates a deeper issue.

“Hollow cubes are often a symptom of temperature imbalance or insufficient fill time. They signal inefficiency long before total failure.” — Carlos Mendez, Appliance Repair Technician with 15+ years of experience

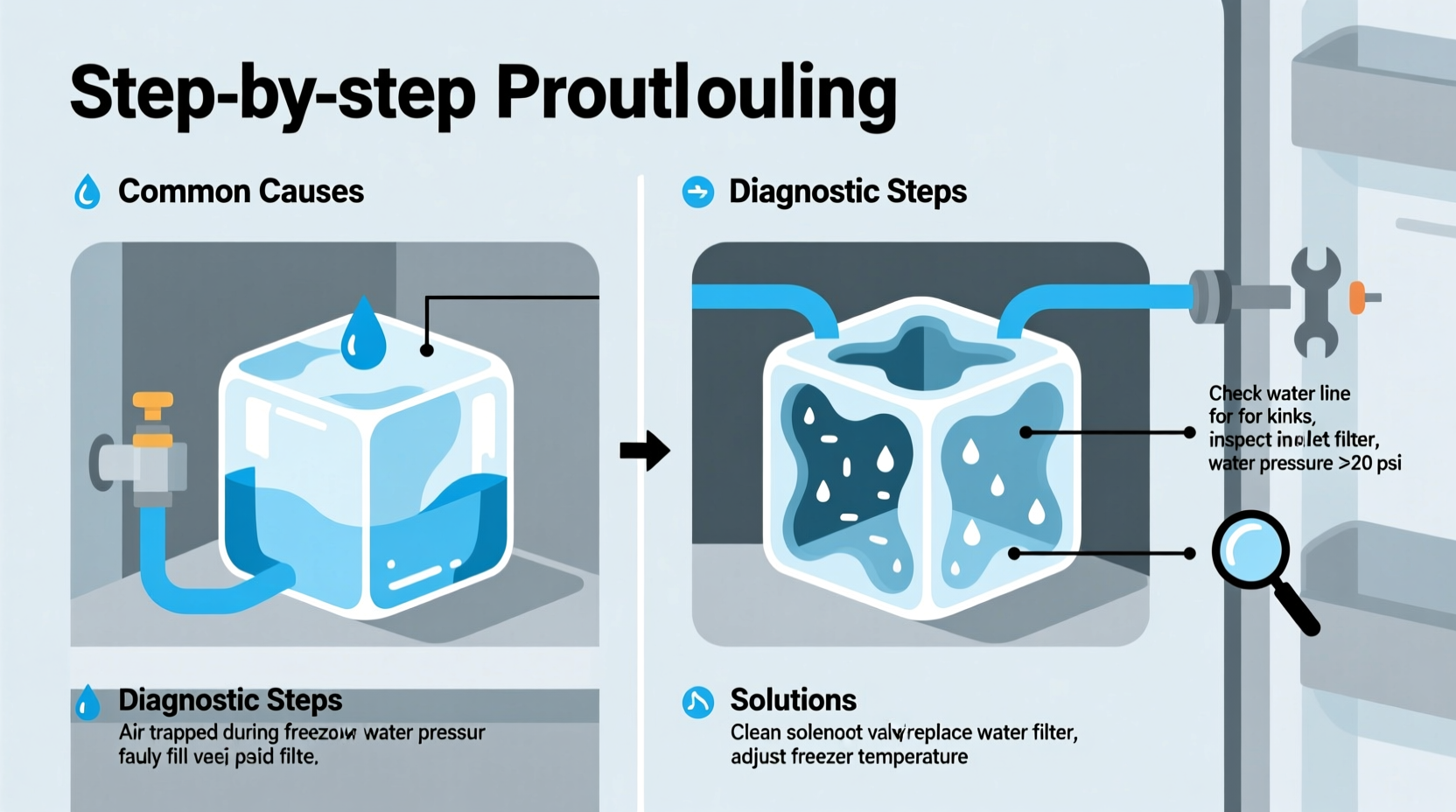

Common Causes of Hollow Ice Cubes

Several interrelated factors can lead to hollow ice production. Identifying which one applies to your situation is the first step toward resolution.

1. Inadequate Freezer Temperature

If your freezer isn’t cold enough, the water in the ice mold won’t freeze completely before the harvest cycle begins. Most manufacturers recommend a freezer temperature of 0°F (-18°C) or lower for optimal ice production. A slightly warmer environment slows freezing, especially in the center of the cube.

2. Short Fill Cycle or Low Water Pressure

Ice makers rely on a precise volume of water delivered during each cycle. If the fill valve isn’t opening fully or water pressure is low (often below 20 psi), the mold may not receive enough water. This leads to shallow filling, rapid surface freezing, and hollow centers due to incomplete freezing.

3. Faulty or Clogged Water Inlet Valve

The water inlet valve controls how much water enters the ice maker. Over time, mineral deposits from hard water can restrict flow. A partially clogged valve reduces water volume, resulting in underfilled molds and fragile, hollow cubes.

4. Malfunctioning Thermostat or Sensor

Some ice makers use sensors to determine when ice is fully frozen. If the sensor is dirty or miscalibrated, it may trigger the harvest cycle too early—before the core has solidified.

5. Frequent Door Opening or Poor Airflow

Every time the freezer door opens, warm air enters and raises the internal temperature. In kitchens with heavy traffic or poorly sealed doors, temperature fluctuations can interfere with consistent freezing cycles.

Troubleshooting Steps to Fix Hollow Ice Production

Follow this systematic approach to identify and correct the underlying cause of hollow ice cubes.

Step 1: Check Freezer Temperature

- Use a standalone freezer thermometer placed near the ice maker.

- Ensure the reading is consistently at or below 0°F (-18°C).

- If too warm, adjust the thermostat and wait 24 hours before rechecking.

- Inspect door seals for gaps or frost buildup that could allow warm air infiltration.

Step 2: Inspect Water Supply Line and Pressure

- Shut off the water supply and disconnect the line from the back of the fridge.

- Hold the end over a bucket and briefly turn the valve on to test flow.

- Strong, steady flow indicates good pressure; weak dribble suggests a restriction.

- Check for kinks in the tubing, especially near bends or connections.

Step 3: Test the Water Inlet Valve

The inlet valve is located where the water line connects to the refrigerator. Signs of trouble include:

- Visible corrosion or mineral crust around the solenoid.

- Humming noise without water flow (indicates electrical activation but mechanical blockage).

- Intermittent filling or inconsistent ice size.

To clean or replace the valve, power must be disconnected. Replacement valves are model-specific and usually cost between $30–$60.

Step 4: Evaluate Fill Time and Volume

Observe one full cycle. After water enters the mold, note how long it takes to fill and whether the level reaches the intended mark (usually about ⅔ full). Ideal fill time is 5–7 seconds. Less than 4 seconds may indicate insufficient volume.

Step 5: Clean the Ice Maker and Sensors

Mineral deposits and ice residue can interfere with sensors and moving parts. Unplug the refrigerator and:

- Remove the ice bin and wash with warm, soapy water.

- Wipe the mold tray gently with a soft cloth dampened with vinegar solution.

- Clean any visible sensor probes (often near the motor arm) with a cotton swab.

- Flush the water line by blowing compressed air through it (optional).

Step 6: Reset the Ice Maker

Many models have a reset function. Consult your manual, but common methods include:

- Turning the shutoff switch off for 30 seconds, then back on.

- Pressing and holding a reset button (if equipped).

- Unplugging the refrigerator for 5 minutes to reboot control boards.

Do’s and Don’ts When Fixing Hollow Ice Issues

| Do’s | Don’ts |

|---|---|

| ✔ Use filtered water if you have hard water | ✘ Ignore persistent low water pressure |

| ✔ Clean the ice maker every 6 months | ✘ Use sharp tools to remove ice buildup |

| ✔ Verify water line connections are tight | ✘ Operate the ice maker with a kinked supply line |

| ✔ Monitor freezer temp after adjustments | ✘ Bypass safety switches to force a cycle |

| ✔ Replace worn parts promptly | ✘ Delay repairs if cubes become smaller over time |

Mini Case Study: Resolving Hollow Ice in a Busy Household Kitchen

Jamie, a homeowner in Denver, noticed her Samsung refrigerator was producing increasingly hollow ice cubes over several weeks. Initially, she assumed it was normal wear, but when the cubes began breaking apart in drinks, she decided to investigate.

She started by checking the freezer temperature, which read 12°F—too high for efficient freezing. She cleaned the condenser coils (located at the back), which were coated in dust, improving airflow. Next, she tested water pressure and found a weak stream. Upon inspection, the supply line had a slight kink behind the fridge. Straightening it improved flow, but cubes remained inconsistent.

After researching online, Jamie learned about mineral buildup in the inlet valve. She replaced the valve herself using a YouTube tutorial and a $42 part. Within two cycles, solid cubes returned. Her final step was installing a whole-house water filter to reduce future scaling.

This case highlights how multiple small issues—a warm freezer, restricted water flow, and a failing valve—can compound to create noticeable performance problems. Addressing each systematically restored full functionality.

Preventive Maintenance Checklist

Keep your ice maker running smoothly with regular care. Use this checklist every six months:

- ✅ Check freezer temperature with an independent thermometer

- ✅ Inspect water supply line for kinks or leaks

- ✅ Clean the ice bin and mold with mild detergent or vinegar

- ✅ Examine the water inlet valve for signs of corrosion

- ✅ Replace refrigerator water filter (if applicable)

- ✅ Listen for unusual noises during fill or harvest cycles

- ✅ Confirm ice cubes are consistently sized and solid

Frequently Asked Questions

Why do some ice makers naturally produce slightly hollow cubes?

Some modern ice makers are designed for speed, using a quick-freeze method where only the outer shell solidifies before harvesting. The remaining water drains away, creating a hollow center. While not ideal for cooling, this design reduces cycle time. However, if hollowness worsens over time, it likely points to an underlying issue like low water pressure or rising freezer temps.

Can a dirty water filter cause hollow ice?

Yes. A clogged or expired water filter restricts flow to the ice maker, reducing the amount of water that fills the mold. Even if the filter doesn’t trigger a warning light, it should be replaced every six months—or sooner in areas with poor water quality. Restricted flow leads to underfilled molds and incomplete freezing.

Is it safe to use the ice if the cubes are hollow?

Hollow cubes are safe to consume as long as the water supply is clean and the ice maker is well-maintained. However, they melt faster and dilute drinks more quickly. If you notice odd tastes or odors, discard existing ice and clean the bin thoroughly. Also, check for mold or biofilm in stagnant water lines.

Conclusion: Take Action Before Performance Declines Further

Hollow ice cubes are a clear indicator that your ice maker isn’t operating at peak efficiency. Whether caused by temperature fluctuations, low water pressure, or component wear, the issue is almost always fixable with basic tools and a methodical approach. Ignoring the problem may lead to reduced ice output, increased energy use, or even complete system failure. By following the steps outlined—checking temperature, inspecting water flow, cleaning components, and replacing worn parts—you can restore solid, reliable ice production.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?