Nothing disrupts productivity quite like a printer that consistently jams. Whether you're printing work reports, school assignments, or personal documents, paper jams can be frustrating, time-consuming, and even damaging to your printer over time. The good news is that most paper jams are preventable—and often easy to fix once you understand the root causes. This comprehensive guide walks you through the common reasons behind recurring paper jams and provides a detailed, step-by-step approach to diagnosing and resolving them.

Understanding Why Paper Jams Happen

Paper jams occur when paper fails to move smoothly through the printer’s internal mechanisms. While occasional jams can happen due to random misfeeds, frequent jams usually point to an underlying issue—either with the printer, the paper, or how the device is being used. Common causes include:

- Using incorrect or low-quality paper

- Dust, debris, or paper fragments stuck in rollers or trays

- Worn or dirty pickup and separation rollers

- Moisture-damaged or curled paper

- Overloading the paper tray

- Misaligned internal components

- Faulty sensors or mechanical parts

Before jumping into repairs, it's important to recognize that many paper jams stem from simple user errors or maintenance oversights. Addressing these first can save time and avoid unnecessary service calls.

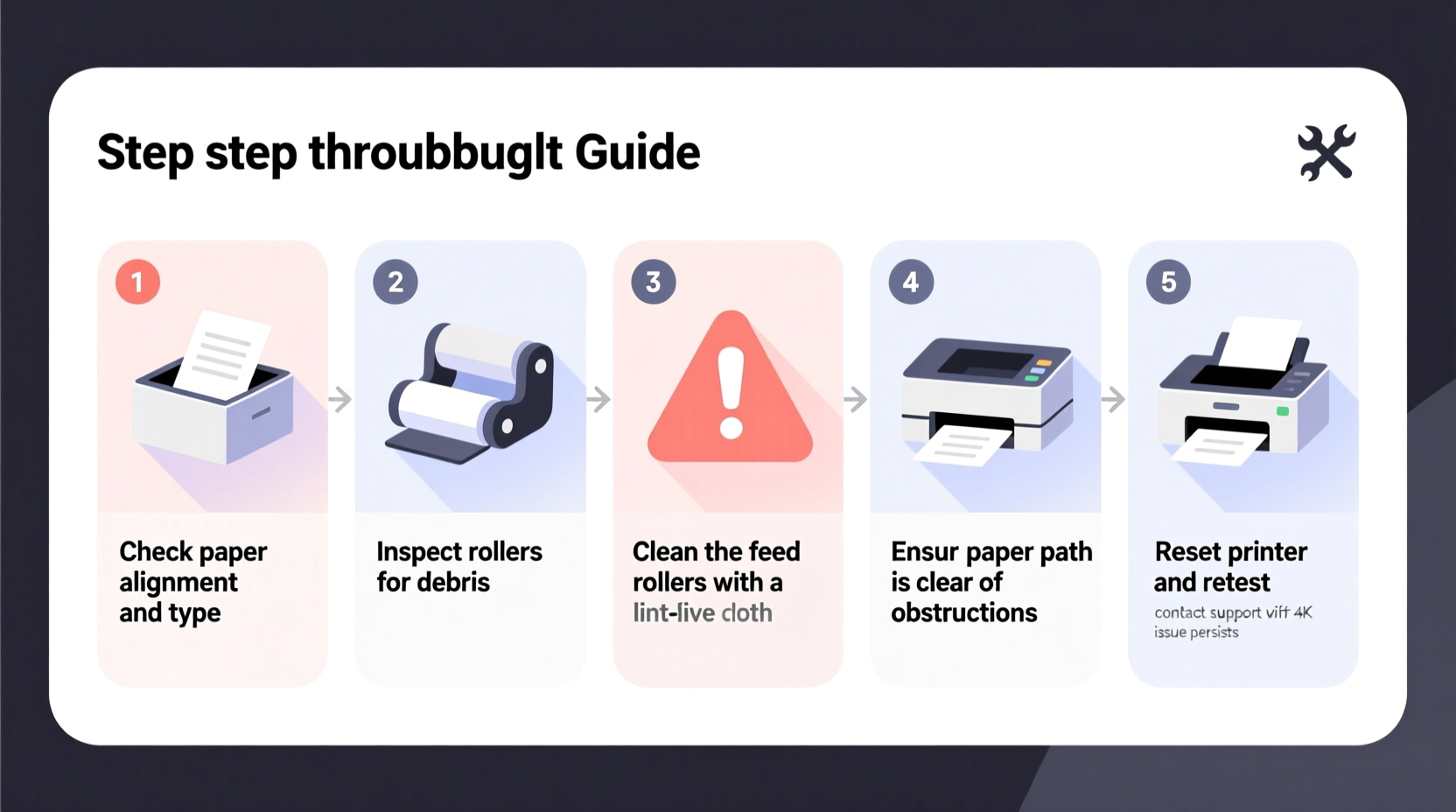

Step-by-Step Troubleshooting Guide

Follow this systematic process to identify and resolve the cause of repeated paper jams. Work through each step carefully—skipping ahead may miss critical issues.

- Turn Off and Unplug the Printer

Ensure safety and prevent mechanical movement during inspection. - Open All Accessible Panels

Check the front output tray, rear access door (if available), and any side panels. Look for visible signs of crumpled paper, torn fragments, or obstructions. - Remove Any Jammed Paper Gently

Pull paper slowly in the direction of the paper path. Never yank it backward, as this can tear the paper or damage rollers. If the paper tears, inspect thoroughly to ensure no small pieces remain inside. - Clean the Paper Feed Rollers

Use a lint-free cloth slightly dampened with water (not dripping) to wipe the rubber rollers in the paper tray and along the feed path. Dirty rollers lose grip and cause misfeeds. Allow them to dry completely before reassembling. - Inspect and Clean the Pickup Mechanism

The pickup roller grabs paper from the tray. If it’s glazed, cracked, or covered in dust, it won’t function properly. Clean it as above. For stubborn residue, use isopropyl alcohol on a cotton swab. - Check the Paper Tray and Guides

Ensure the paper stack is not overloaded (usually no more than 150 sheets for standard printers). Adjust the side and back guides so they hold the paper snugly without bending it. Misaligned guides can skew paper entry. - Examine Paper Quality and Storage

Avoid using wrinkled, folded, or recycled paper with rough edges. Store paper flat in a cool, dry place away from humidity, which causes curling and static buildup. - Test with Fresh, Standard Paper

Load a new ream of 20–24 lb bond paper. Avoid specialty papers (glossy, thick cardstock) unless your printer model supports them. - Run a Printer Self-Clean or Diagnostic

Many modern printers have built-in tools to detect and clear minor feed issues. Consult your manual for self-test options. - Restart and Test Print

Plug the printer back in, power it on, and send a test page. Monitor the feed process closely for any hesitation or noise.

If the Jam Persists: Advanced Checks

When basic steps don’t resolve the issue, consider these deeper factors:

- Check Internal Sensors: Optical sensors detect paper movement. Dust or misalignment can trigger false jam alerts. Use compressed air to clean around sensor locations (refer to your manual).

- Inspect Fuser Unit (Laser Printers): In laser models, jams often occur near the fuser. If paper stops mid-print and feels warm, the fuser rollers may be worn or contaminated.

- Update Firmware: Some manufacturers release firmware updates to improve paper handling logic. Visit the manufacturer’s website and check for updates specific to your model.

- Listen for Unusual Noises: Grinding or clicking sounds may indicate a broken gear or motor failure requiring professional repair.

Do’s and Don’ts When Handling Paper Jams

| Do’s | Don’ts |

|---|---|

| Always power down before clearing jams | Never force paper out abruptly |

| Use manufacturer-recommended paper types | Don’t overload the input tray |

| Clean rollers every 3–6 months | Avoid touching rollers with oily hands |

| Store paper in sealed containers if in humid areas | Don’t use bent, creased, or torn paper |

| Align paper guides firmly against the stack | Never ignore recurring error messages |

Real-World Example: Office Printer Recovery

In a mid-sized accounting firm in Portland, employees reported daily paper jams in their shared HP LaserJet M404dn. The issue escalated during tax season, delaying client document processing. An IT consultant was called in and followed a structured diagnostic:

Initial inspection revealed no visible paper fragments. However, the pickup roller was shiny and slick—signs of wear. The paper tray was overfilled with mixed-weight stock, including envelopes and recycled sheets. The consultant cleaned the rollers, replaced the pickup tire (an inexpensive part), and standardized paper usage across the office. They also scheduled monthly maintenance reminders.

Result: Zero paper jams reported in the following three months. Employee satisfaction improved, and the firm avoided the cost of premature printer replacement.

“Over 70% of recurring paper jams we see are due to improper media or neglected roller maintenance. A five-minute cleaning can save hours of downtime.” — David Lin, Field Service Technician, OfficeTech Support Group

Preventative Maintenance Checklist

To minimize future jams, adopt this routine:

- ✅ Clean feed and pickup rollers every 3–6 months

- ✅ Inspect paper tray for debris weekly

- ✅ Use only compatible, high-quality paper

- ✅ Keep paper stored in a dry, flat environment

- ✅ Align paper guides correctly before each load

- ✅ Run a test page after refilling paper

- ✅ Update printer firmware biannually

- ✅ Replace worn rollers or parts as recommended by the manufacturer

For high-volume environments, consider scheduling professional servicing once per year. Technicians can disassemble internal components, lubricate gears, and replace aging parts before they fail.

Frequently Asked Questions

Why does my printer jam even with brand-new paper?

Even new paper can cause jams if it’s been stored improperly—exposed to moisture, stacked unevenly, or loaded too tightly in the tray. Additionally, internal components like rollers or sensors may be dirty or failing, making the printer sensitive to slight variations in paper thickness or alignment.

Can using third-party ink or toner cause paper jams?

Not directly. Ink or toner doesn’t affect paper feeding mechanics. However, low-quality cartridges may cause overheating or inconsistent fusing (in laser printers), leading to paper sticking or incomplete ejection. Stick to reputable brands for best results.

Is it worth repairing an old printer with frequent jams?

It depends on the model and repair cost. If the printer is more than 5 years old and requires replacement of multiple parts (e.g., rollers, fuser, sensors), investing in a newer, more reliable model may offer better long-term value. Modern printers often have smarter paper handling and diagnostics.

Conclusion: Take Control of Your Printing Experience

Recurring paper jams aren’t just an annoyance—they’re a signal that something needs attention. By understanding the mechanics behind paper feeding and adopting a proactive maintenance mindset, you can eliminate most jams before they happen. The key lies in consistent care: using the right paper, keeping components clean, and addressing small issues before they become major failures.

Whether you're managing a home office or supporting a busy workplace, taking the time to troubleshoot and maintain your printer pays dividends in reliability, efficiency, and peace of mind. Start applying these steps today, and transform your printer from a source of frustration into a dependable tool.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?