Printer jams are among the most frustrating office and home annoyances—especially when they happen repeatedly. You load fresh paper, press print, and within seconds, an error message appears: “Paper Jam.” Even after clearing the blockage, the problem returns. While many assume this is a sign of hardware failure or aging equipment, the truth is far more mundane: poor maintenance and overlooked details cause the majority of recurring jams. Most people clear the visible paper and resume printing without addressing the root causes. This article reveals the hidden reasons behind frequent printer jams and outlines practical, often-missed maintenance steps that can restore reliability to your device.

Understanding the Common Causes of Printer Jams

Before diving into solutions, it's essential to understand what actually causes a paper jam. At its core, a jam occurs when paper fails to move smoothly through the printer’s internal path. This disruption can stem from mechanical, environmental, or user-related factors.

The most commonly cited causes include:

- Paper misalignment in the tray

- Moisture-damaged or wrinkled paper

- Dirt or debris in rollers and feed paths

- Worn or contaminated pickup rollers

- Incorrect paper type or weight for the printer model

- Overfilled paper trays

While these are valid, the deeper issue lies not in their existence but in how consistently they’re ignored during routine use. For instance, even high-quality paper can become problematic if stored improperly. Likewise, rollers that look clean may still lack grip due to invisible residue buildup.

“Most printer jams aren’t caused by sudden failures—they’re the result of gradual neglect. A little attention every few weeks prevents months of frustration.” — David Lin, Senior Technician at PrintCare Solutions

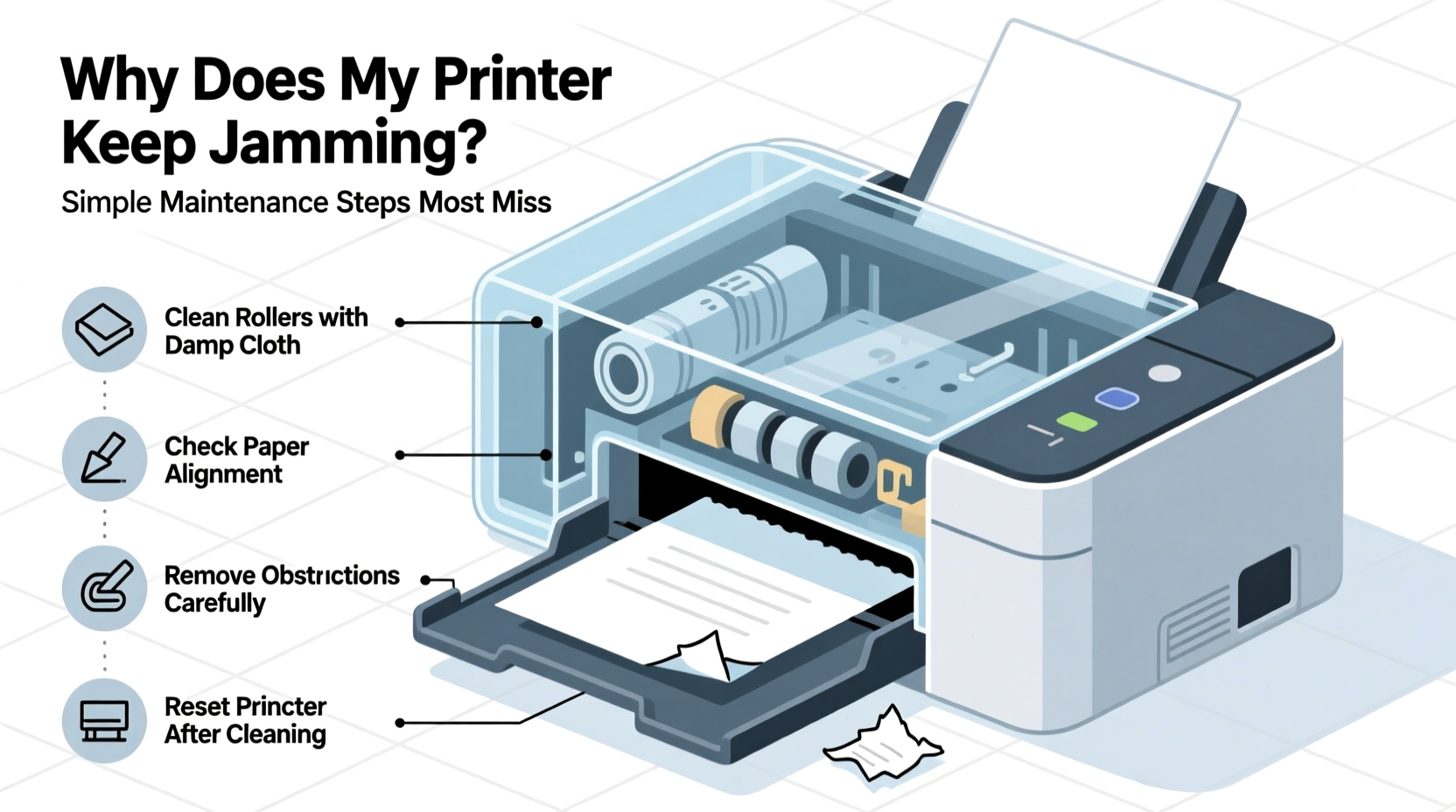

Step-by-Step Guide to Clearing and Preventing Jams

Clearing a jam isn’t enough. To stop it from recurring, follow this comprehensive step-by-step process that goes beyond the basic manual instructions.

- Power down and unplug the printer. Safety first. Turning off and unplugging eliminates risk of accidental movement during cleaning.

- Open all accessible panels. This includes the rear access door, front output tray, and any side covers. Most manufacturers design printers with serviceable pathways, but users rarely open them all.

- Remove all paper from trays. Check both main and auxiliary trays. Inspect each sheet for curls, tears, or moisture damage.

- Gently extract stuck paper. Pull slowly in the direction of paper flow. Never yank. If resistance occurs, reverse slightly and try again to avoid tearing.

- Inspect the entire paper path. Use a flashlight to examine tight corners where small fragments often hide. Even a tiny piece of torn paper can trigger repeated jams.

- Clean the pickup and separation rollers. Dampen a lint-free cloth with distilled water (not tap water) and gently wipe each roller. Rotate manually to clean the full circumference. Allow to dry completely before reassembly.

- Check for worn components. Look for cracks or flat spots on rollers. If rubber feels glazed or slick, it’s time for replacement.

- Reassemble and reload paper properly. Fan the stack before loading to reduce static cling and ensure alignment against guides without over-tightening.

- Run a test print. Start with a single-page document to verify smooth operation.

What Most Users Miss: The Hidden Maintenance Steps

Standard troubleshooting guides cover surface-level fixes. But long-term reliability depends on habits most users never adopt. These overlooked practices make the critical difference between a printer that jams monthly and one that runs smoothly for years.

1. Clean Internal Rollers Monthly

Even if your printer sees light use, dust and paper fibers accumulate on rollers. Over time, this residue creates a slick film that reduces grip. Cleaning once a month with a lightly dampened microfiber cloth restores traction and prevents slips.

2. Rotate Paper Stock

Storing the same ream for months leads to edge curling and moisture absorption, especially in humid environments. Rotate your paper supply—use older reams first—and store in sealed containers if humidity exceeds 50%.

3. Avoid Mixing Paper Types in One Tray

Using both glossy photo paper and standard copy paper in the same tray confuses the printer’s feed mechanism. Different thicknesses and textures lead to inconsistent pickup pressure. Dedicate trays to specific paper types.

4. Check Alignment Guides Regularly

Many users set the paper guides once and forget them. Over time, vibrations or accidental bumps can shift them outward, allowing paper to skew during feeding. Ensure guides touch the edges snugly—but not tightly enough to crumple the paper.

5. Replace Aging Rollers Before They Fail

Pickup rollers degrade over time. Most last 15,000–20,000 pages. If your printer has printed several thousand pages, consider proactive replacement rather than waiting for slippage or jams to escalate.

Maintenance Checklist: Prevent Jams Before They Happen

Use this checklist monthly to maintain optimal printer performance and avoid unexpected jams.

| Action | Frequency | Notes |

|---|---|---|

| Fan and reload paper | Every time you refill | Prevents static and misfeeds |

| Wipe pickup rollers | Monthly | Use distilled water and lint-free cloth |

| Inspect paper path | Quarterly or after major jam | Look for debris or torn paper remnants |

| Replace rollers | Every 15,000–20,000 pages | Check manufacturer specs |

| Verify paper type settings | Before each special media print | Match driver settings to paper loaded |

| Update firmware | Biannually | Improves feed algorithms and error handling |

Real Example: How a Small Office Fixed Chronic Jams

A marketing firm in Portland experienced daily printer jams across two shared devices. Staff would clear jams multiple times per day, wasting time and damaging morale. After consulting a technician, they discovered three key oversights:

- The paper was stored under a window, exposing it to sunlight and temperature swings.

- Rollers were coated in a fine layer of toner dust from nearby laser printers.

- One tray had been overloaded consistently, causing misalignment.

The solution was straightforward: relocate paper storage to a climate-controlled cabinet, clean rollers monthly, and enforce a “never exceed fill line” rule. Within two weeks, jams dropped from five per week to zero. Productivity improved, and the IT team reported fewer support tickets.

This case underscores a universal truth: printer reliability isn’t about perfect machines—it’s about consistent care.

Do’s and Don’ts of Printer Paper Handling

Mistakes in paper management are responsible for over half of all jams. Follow this guide to avoid common pitfalls.

| Do’s | Don’ts |

|---|---|

| Store paper in a cool, dry place away from direct sunlight | Leave paper exposed on desks or near windows |

| Fan paper stacks before loading | Load paper directly from the box without separating sheets |

| Use the correct paper weight for your printer (usually 20–24 lb) | Use cardstock or labels unless specifically supported |

| Align paper guides snugly against the stack | Leave wide gaps between paper and guides |

| Print high-volume jobs in batches with short pauses | Send 100-page documents without monitoring progress |

Frequently Asked Questions

Why does my printer jam even with brand-new paper?

New paper can still be damaged by environmental exposure. Humidity causes fibers to swell, leading to curling and sticking. Additionally, some off-brand papers have inconsistent coatings that increase friction. Always store paper in sealed packaging until use and purchase reputable brands for reliable performance.

Can software settings cause paper jams?

Indirectly, yes. Selecting the wrong paper type in your print driver (e.g., choosing “Labels” when using plain paper) alters how the printer feeds sheets. It may apply incorrect pressure or speed, increasing slip or double-feed risk. Always match the driver setting to the physical paper loaded.

How do I know if my rollers need replacing?

Signs include frequent multi-sheet pickups, slow feeding, or jams occurring immediately upon startup. Visually, rollers may appear shiny, cracked, or flattened. If cleaning doesn’t restore grip, replacement is necessary. Most models have user-replaceable rollers available from the manufacturer or third-party suppliers.

Conclusion: Take Control of Your Printer’s Performance

Repeated printer jams aren’t inevitable. They’re symptoms of neglected maintenance and subtle user errors that compound over time. By understanding the mechanics of paper feeding, committing to regular cleaning, and respecting the limitations of your equipment, you can eliminate most jams before they occur. The steps outlined here—cleaning rollers, managing paper storage, aligning guides, and replacing worn parts—are simple but profoundly effective. They require only minutes each month but deliver months of uninterrupted printing.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?