Thread breakage is one of the most frustrating issues sewists face—whether you're a beginner or a seasoned tailor. It disrupts workflow, damages fabric, and can make even simple projects feel overwhelming. The good news is that thread breakage is rarely random. It’s usually a symptom of an underlying mechanical, technical, or material issue. By systematically diagnosing the root cause, you can eliminate the problem for good. This guide walks through the most common reasons thread breaks occur and how to fix them efficiently.

Understanding Thread Tension and Machine Mechanics

Before diving into specific fixes, it's important to understand how a sewing machine works. Thread travels from the spool, through tension discs, down to the take-up lever, then through the needle. Any obstruction or imbalance in this path can lead to breakage. The two primary tension systems—the upper (needle) tension and the bobbin (lower) tension—must work in harmony. Too much tension strains the thread; too little causes looping and skipped stitches, which can also result in snapping.

Modern machines are precision instruments. Even minor misalignments, lint buildup, or using incorrect accessories can throw off performance. Thread quality also plays a significant role. Cheap or old thread frays easily under stress, especially at high speeds.

Common Causes of Thread Breakage and How to Fix Them

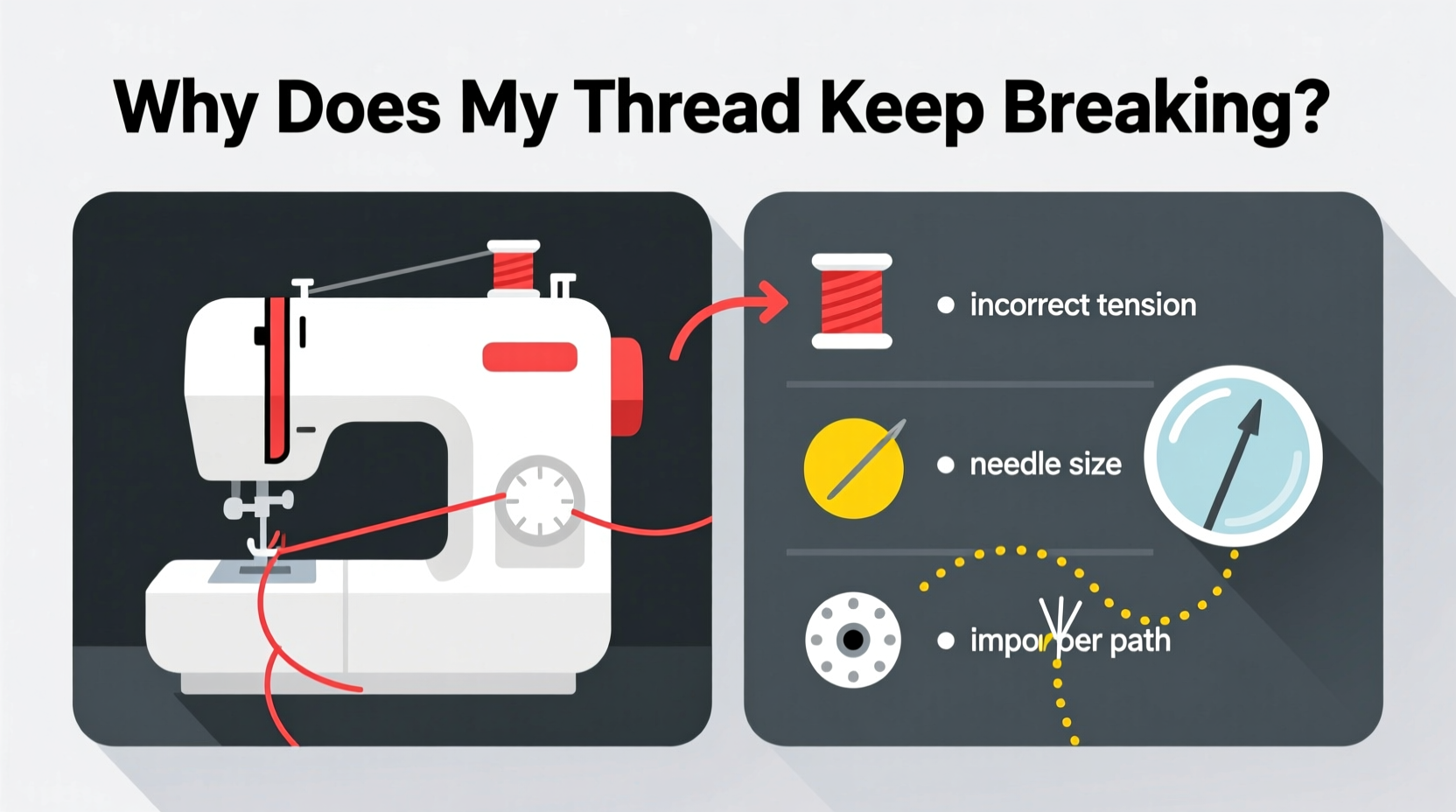

Thread breakage rarely has a single cause. More often, it's the result of multiple small issues compounding. Below are the top culprits and their solutions.

1. Incorrect Needle Size or Type

The needle is the final point of contact before the thread forms a stitch. Using the wrong needle can create friction, bend the needle, or damage the thread. For example, a fine needle used on heavy denim will struggle, causing thread stress and breakage.

- Fabric too thick for needle? Upgrade to a heavier needle (e.g., 90/14 or 100/16).

- Using universal needle on stretch fabric? Switch to a ballpoint or stretch needle.

- Is the needle inserted correctly? Flat side should face the back, and it must be pushed all the way up.

2. Poor Quality or Old Thread

Low-grade thread has inconsistent thickness and weak fibers. Over time, even good thread degrades—exposure to light, humidity, and temperature changes weakens it. If your thread looks fuzzy, brittle, or sheds lint excessively, replace it.

“Always match your thread quality to your project. A $2 spool won’t hold up on couture garments.” — Linda Torres, Industrial Sewing Instructor

3. Improper Threading Path

If the thread misses a guide or tension disc, tension becomes uneven. This creates sudden strain points, especially during high-speed stitching. Always rethread the machine from scratch when troubleshooting.

4. Dirty or Lint-Clogged Bobbin Area

Lint and thread fragments accumulate under the needle plate and around the bobbin case. This restricts smooth thread flow and increases friction. Machines used frequently may need cleaning after every 8–10 hours of use.

5. Incorrect Tension Settings

Excessively tight upper tension is a leading cause of breakage. However, loose bobbin tension can also cause problems by creating drag. Tension should be balanced so both threads meet in the middle of the fabric layers.

| Symptom | Most Likely Cause | Solution |

|---|---|---|

| Top thread breaks repeatedly | Upper tension too tight, needle too small, or incorrect threading | Rethread, reduce tension, check needle size |

| Bobbin thread breaks | Bent bobbin case, lint buildup, or incorrect bobbin winding | Clean area, inspect bobbin, re-wind evenly |

| Thread snaps only at start of seam | Pulling thread too hard or needle position issue | Hold thread tails for first few stitches, adjust needle bar height if needed |

| Breakage increases with speed | Poor thread quality or machine timing issue | Use higher-grade thread, have machine serviced |

Step-by-Step Troubleshooting Timeline

Follow this logical sequence to isolate and resolve the issue:

- Stop and unplug the machine. Safety first—never adjust internal components while powered.

- Remove the needle and inspect it. Look for bends, burrs, or dullness. Replace if questionable.

- Clean the bobbin area thoroughly. Use a small brush and lint-free cloth to remove debris.

- Rethread the entire machine with the presser foot up. Ensure thread passes through every guide and tension disc.

- Check the spool cap and holder. A spool that wobbles or spins unevenly can cause erratic tension.

- Test tension on scrap fabric. Use the same materials as your project. Adjust upper tension in small increments.

- Run a test seam slowly, then increase speed. Observe where and when breakage occurs.

- Inspect machine timing if problem persists. Misaligned hook and needle require professional adjustment.

Mini Case Study: Fixing Persistent Breakage on a Vintage Machine

Sarah, a quilt maker, struggled with frequent thread snapping on her 1970s Singer. She replaced needles, changed thread brands, and adjusted tension—but the issue returned within minutes. After following the full checklist, she discovered the real culprit: a worn bobbin case spring. The spring had lost its tension, causing erratic bobbin thread delivery. Replacing the spring (a $12 part) resolved the issue completely. Sarah now performs monthly maintenance checks and keeps a log of service dates. Her machine runs smoother than it has in decades.

Essential Checklist: Prevent Thread Breakage Before It Starts

- ✅ Use the correct needle for fabric weight and type

- ✅ Rethread the machine with the presser foot up

- ✅ Clean lint from bobbin area after every major project

- ✅ Use high-quality thread appropriate for the fabric

- ✅ Check that the spool rotates freely with the right cap size

- ✅ Test stitches on scrap fabric before starting

- ✅ Replace needles every 8–10 hours of sewing

- ✅ Store thread away from sunlight and moisture

Frequently Asked Questions

Why does my thread keep breaking even with a new needle?

A new needle helps, but it doesn’t solve everything. Double-check that the needle is the correct size and type for your fabric. Also verify that the machine is threaded properly—missing a guide or tension disc is a common oversight. Finally, inspect the thread path for rough spots or burrs on the needle plate or hook.

Can the type of fabric cause thread breakage?

Absolutely. Dense fabrics like denim or canvas require stronger thread and heavier needles. Delicate fabrics like silk can snag on rough needle eyes. Always match your thread, needle, and tension to the fabric. Testing on a scrap piece first prevents costly mistakes.

How do I know if my bobbin is wound correctly?

A properly wound bobbin has even, consistent tension from center to edge. It shouldn’t be overfilled (no bulging), and the thread should unwind smoothly without tangling. Wind bobbins at medium speed and trim excess thread from the ends.

Maintaining Long-Term Machine Health

Prevention is always better than repair. Regular maintenance extends your machine’s life and reduces downtime. Most manufacturers recommend professional servicing every 1–2 years, depending on usage. At home, wipe down the machine after each use, cover it when not in use, and store in a dust-free environment. Use only manufacturer-recommended oil—over-oiling attracts lint and gumms up moving parts.

“A sewing machine is like a car: it needs fuel, tune-ups, and care to perform well.” — Carlos Mendez, Sewing Machine Technician with 25 years’ experience

Conclusion

Thread breakage isn’t a mystery—it’s a signal that something in your sewing system needs attention. Whether it’s a worn needle, dirty bobbin case, or mismatched materials, the solution lies in careful observation and methodical testing. By applying the steps in this guide, you’ll spend less time frustrated and more time creating. Don’t let thread issues discourage you. With the right knowledge, every break becomes a learning opportunity.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?