String lights add charm and warmth to homes, patios, and holiday displays. But when a section suddenly goes dark while the rest remains lit, it can be frustrating. Unlike older series-wired strands where one dead bulb killed the whole string, modern mini-light sets often use parallel or shunted wiring that keeps most bulbs glowing even if one fails. Yet partial failures still occur — usually due to a single faulty bulb, loose connection, or damaged wire segment. Understanding why this happens and how to systematically locate the problem saves time, prevents repeated frustration, and extends the life of your lighting display.

How Modern Light Strands Are Wired

Most contemporary Christmas and decorative light strands use a hybrid design: multiple small circuits wired in parallel, each containing several bulbs in series. This means that within a single strand, different sections operate independently. If one bulb burns out in a series group, only that segment goes dark — not the entire string. This setup improves reliability but complicates troubleshooting because failure is localized rather than total.

The bulbs themselves are typically low-voltage incandescent or LED types with internal shunts. A shunt is a tiny wire inside the bulb base designed to activate when the filament breaks, allowing current to bypass the dead bulb and keep the circuit closed. However, shunts don’t always work perfectly. Corrosion, manufacturing defects, or physical damage can prevent them from engaging, breaking the circuit for that entire section.

“Modern light strings are more reliable than ever, but their segmented design means you need precision diagnostics when part of the strand fails.” — James Reed, Electrical Systems Technician with 18 years in residential lighting

Common Causes of Partial Failure in Light Strands

When only one section of your light strand stops working, several factors could be responsible. Identifying the root cause streamlines repair and helps avoid future issues.

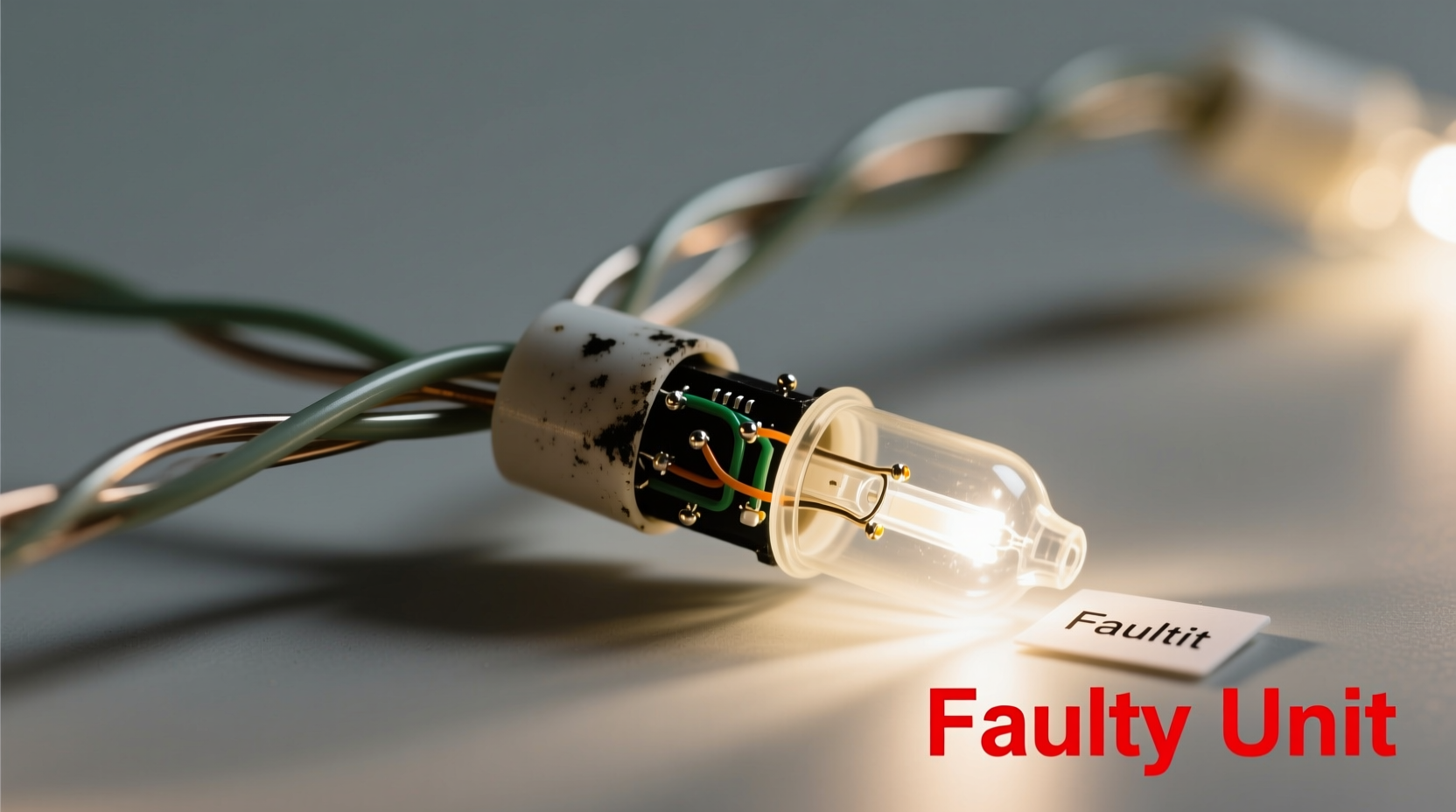

- Faulty bulb: The most common culprit. Even with shunts, some bulbs fail in a way that interrupts the circuit.

- Loose bulb: Vibration or improper seating can disconnect a bulb from its socket, breaking continuity.

- Damaged wire: Pinched, chewed, or frayed wires — especially near connectors or between sockets — can interrupt power flow.

- Corroded contacts: Outdoor exposure leads to oxidation on bulb bases or socket terminals, reducing conductivity.

- Failed shunt: The backup path inside a bulb doesn’t activate, leaving the circuit open after filament burnout.

- Section-specific fuse: Some advanced strands include inline fuses for individual segments; a blown micro-fuse may affect only one area.

Step-by-Step Guide to Finding the Faulty Bulb

Locating the defective component in a partially darkened light strand requires methodical testing. Follow this proven process to identify and resolve the issue efficiently.

- Unplug the strand immediately. Safety first — never work on live electrical devices.

- Inspect visually. Look for cracked bulbs, discolored sockets, or visible wire damage along the dark section.

- Check for loose bulbs. Gently twist each bulb in the dark segment to ensure it’s fully seated. Reseat any that feel loose.

- Test known-good bulbs. Remove a working bulb from the lit portion and insert it into each position in the dark section. Plug in the strand briefly after each swap to test.

- Use a bulb tester or voltage detector. These inexpensive tools detect current flow without requiring full illumination. Run the probe along the wire just before and after each socket in the dark section to find where voltage drops off.

- Replace suspect bulbs one at a time. Start with the first non-working socket. Insert a new bulb and test. Continue down the line until the section lights up.

- Examine the wire path. If no bulb replacement fixes the issue, inspect the wiring between sockets for cuts, kinks, or rodent damage.

This approach minimizes guesswork and avoids replacing all bulbs unnecessarily. In many cases, only one or two components are responsible for the outage.

Tips and Tools for Efficient Troubleshooting

Having the right tools and techniques makes diagnosing partial failures faster and safer.

| Tool | Purpose | Recommended Use |

|---|---|---|

| Bulb Tester (e.g., LightKeeper Pro) | Sends a pulse to clear shunt failures | First-line tool for stuck shunts in incandescent strands |

| Multimeter | Measures voltage and continuity | Verify power delivery across sockets and wires |

| Needle-Nose Pliers | Remove stubborn bulbs | Grip base gently to avoid socket damage |

| Splice Connectors | Repair broken wires | Waterproof versions for outdoor use |

| Extra Replacement Bulbs | On-hand replacements | Match voltage and size exactly |

Mini Case Study: Holiday Lights That Wouldn’t Stay On

Sarah in Portland had a 50-bulb icicle light set that consistently went dark in three lower strands every year. She replaced the entire string twice before deciding to investigate. After unplugging the lights, she used a multimeter to check continuity and found that voltage reached the first working section but dropped to zero at the third connector. Upon closer inspection, she discovered a pinched wire where the strand passed through a gutter bracket. The insulation was worn, and copper strands were corroded. She cut out the damaged section, spliced in a new connector, and sealed it with heat-shrink tubing. The lights worked perfectly thereafter — and have lasted four seasons since.

Sarah’s experience shows that recurring issues often stem from environmental stress points, not random bulb failure. Regular inspection of mounting points and wire routing can prevent repeat problems.

Do’s and Don’ts When Repairing Light Strands

Avoid common mistakes by following these guidelines:

| Do’s | Don’ts |

|---|---|

| Unplug before servicing | Never attempt repairs while plugged in |

| Use exact replacement bulbs | Don’t mix voltages or bulb types |

| Test with a known-working bulb | Don’t assume all dark bulbs are bad |

| Inspect wire paths for damage | Ignore signs of rodent activity or weather wear |

| Store lights coiled loosely with protectors | Throw lights into a box haphazardly |

“The biggest mistake people make is replacing every bulb instead of isolating the fault. One bad connection can mimic widespread failure.” — Linda Cho, Consumer Electronics Repair Specialist

Preventive Maintenance Checklist

To reduce future failures, perform these checks annually before installation:

- ✔️ Inspect entire length for cracked insulation or exposed wires

- ✔️ Ensure all bulbs are snug and undamaged

- ✔️ Clean socket contacts with a cotton swab and isopropyl alcohol

- ✔️ Test strand on a grounded outlet using a GFCI adapter (especially outdoors)

- ✔️ Replace aging strands showing frequent issues or discoloration

- ✔️ Store in labeled containers with soft padding to prevent crushing

Frequently Asked Questions

Can a single bulb really cause an entire section to go dark?

Yes, even in modern strings. While shunts are designed to bypass failed filaments, they can fail due to age, moisture, or poor manufacturing. When the shunt doesn’t activate, the circuit breaks and the entire series section loses power.

Why do my lights work for a few hours then go out again?

This often indicates an intermittent connection. It could be a loose bulb that shifts with temperature changes, a cracked solder joint, or a wire that intermittently touches due to vibration. Once the connection warms up or moves slightly, the circuit breaks. This requires careful inspection under load or with a continuity tester.

Are LED strands easier to troubleshoot than incandescent ones?

In some ways, yes. LEDs consume less power and generate less heat, reducing stress on components. However, many LED strands use constant-current drivers or integrated controllers, meaning a single failed diode or driver chip can disable a whole segment. They’re more efficient but sometimes harder to repair than traditional bulbs.

Final Thoughts and Action Steps

A dark section in your light strand isn’t a reason to discard the whole set. With basic tools and systematic testing, you can restore full function and extend the lifespan of your decorations. Start by ruling out simple causes like loose bulbs or tripped shunts. Then move to targeted diagnostics using testers or substitution methods. Pay attention to recurring failure points — they often reveal hidden damage in wiring or installation flaws.

Regular maintenance, careful storage, and prompt repairs not only save money but also enhance safety. Damaged cords and corroded contacts increase fire risk, especially in outdoor or high-moisture environments. Addressing small issues early prevents larger hazards later.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?