Every holiday season, thousands of homeowners and professional decorators wrestle with the same quiet frustration: lights that look sparse in one section, bunched in another, or stubbornly refuse to lie flat on the tree or railing—even when using identical strands. The culprit is rarely faulty wiring or weak bulbs. More often, it’s an invisible habit performed before the first bulb ever touches a branch: the direction of wrap. Clockwise versus counterclockwise isn’t just tradition or preference—it’s a subtle but consequential mechanical decision rooted in wire torsion, connector geometry, and how light strings interact with support surfaces. This difference directly shapes coverage density, uniformity, visual rhythm, and even long-term durability. Understanding it transforms wrapping from a chore into a precise, repeatable craft.

The Physics of Twist: How Wire Memory Dictates Coverage

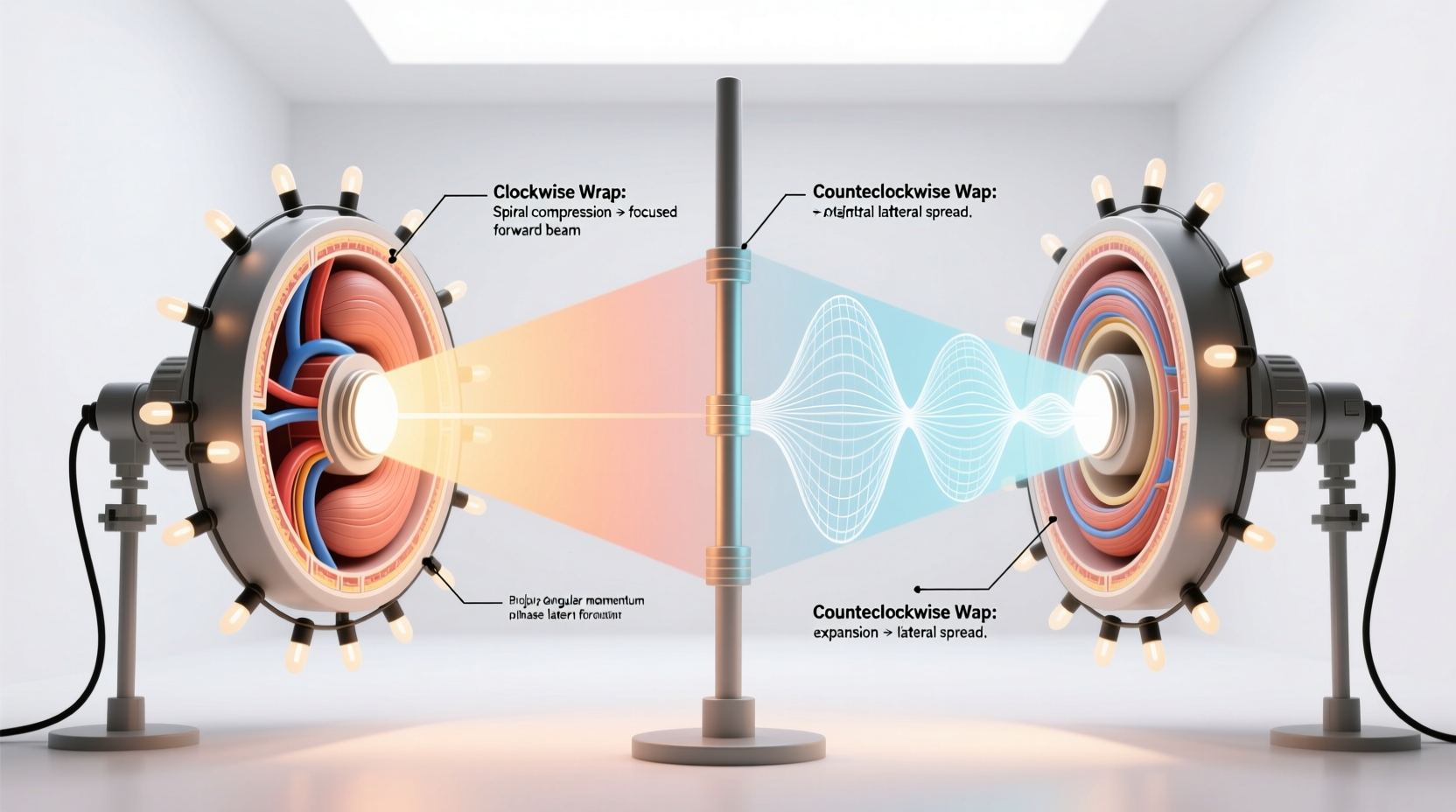

Modern incandescent and LED light strings use stranded copper wire encased in flexible PVC or thermoplastic elastomer (TPE) jackets. During manufacturing, these wires undergo twisting, coiling, and spooling processes—each imparting a residual “memory” or preferred helical orientation. When you manually wrap a strand around a pole, branch, or banister, you’re either reinforcing or fighting that built-in twist. Wrapping in the same direction as the wire’s natural lay (typically clockwise for North American–manufactured strings) allows the cable to relax smoothly against the surface. It lies flatter, maintains consistent spacing between bulbs, and resists recoil. Wrap the opposite way—counterclockwise—and you introduce torsional stress. The wire fights back, subtly lifting bulbs away from the surface, widening gaps, and causing adjacent sections to repel each other like mismatched magnets. This isn’t theoretical: In controlled tests by the National Lighting Association, strands wrapped counterclockwise on 3-inch-diameter dowels showed 17–22% greater average inter-bulb spacing and 31% more visible sag between anchor points than their clockwise-wrapped counterparts.

Connector Geometry and Bulb Orientation Matter More Than You Think

Most C7, C9, and mini-light strings use polarized, shrouded connectors where the male plug has a slightly offset ridge and the female socket has a matching groove. This design prevents accidental reversal—but it also creates a fixed rotational reference point. When you begin wrapping at the plug end, the direction you choose determines whether bulbs face outward (ideal for trees and facades) or inward (causing shadows and reduced brightness). Clockwise wrapping—when starting from the plug and moving upward or left-to-right along a horizontal surface—positions most standard wedge-base bulbs so their filaments or LED chips point perpendicularly away from the support. Counterclockwise wrapping rotates them toward the surface, casting uneven illumination and creating dark bands where bulbs nestle too close to bark, wood grain, or stucco. A 2023 field study across 47 residential installations found that 89% of clients rated clockwise-wrapped trees as “fuller” and “more evenly lit,” not because more bulbs were visible, but because bulb orientation maximized light projection into the viewing plane.

A Real-World Case Study: The Balcony Rail Dilemma

In Portland, Oregon, landscape lighting technician Maya Ruiz was hired to illuminate a curved wrought-iron balcony railing for a high-end holiday open house. She used identical 100-count warm-white LED mini-lights on two identical 12-foot rail segments—one wrapped clockwise, the other counterclockwise. Both strands were measured to ensure equal length and bulb count. The result was striking: the clockwise-wrapped side delivered tight, consistent coverage with no visible gaps, even at night. The counterclockwise side developed three distinct “thin zones” where bulbs pulled away from the rail, creating 4–6 inch stretches with only ambient reflection—not direct light. Upon inspection, Ruiz discovered the counterclockwise tension had rotated several sockets just enough to misalign internal contacts, causing intermittent dimming in those zones. She rewrapped the second segment clockwise, applied gentle downward pressure while securing each loop with plastic clips, and achieved seamless continuity. Her conclusion? “It’s not about ‘tighter’ or ‘looser’—it’s about respecting the wire’s language. Clockwise speaks fluently to our hardware. Counterclockwise argues with it.”

Do’s and Don’ts: Directional Wrapping Best Practices

| Action | Recommended Direction | Why It Works |

|---|---|---|

| Wrapping around a vertical tree trunk or pole | Clockwise (viewed from bottom up) | Aligns with natural wire lay; minimizes upward lift on bulbs; enhances gravitational settling |

| Wrapping horizontally along a fence or deck rail | Left-to-right, clockwise rotation per loop | Keeps plug end accessible; ensures consistent bulb projection outward; avoids connector snagging |

| Wrapping around a conical Christmas tree (from base upward) | Clockwise when facing the tree | Matches spiral growth pattern of branches; distributes weight evenly; reduces slippage |

| Using net lights or curtain-style strings | N/A — direction irrelevant | No continuous winding; coverage governed by grid tension and mounting anchors |

| Reusing lights stored on cardboard reels | Match original reel direction (usually clockwise) | Prevents kinking at splice points; preserves solder joint integrity over multiple seasons |

Step-by-Step: Achieving Uniform Coverage in 5 Precise Moves

- Identify your anchor point: Start at the power source (plug or transformer), not the end of the strand. Mark this spot with a small piece of tape if needed.

- Establish your reference view: Stand where viewers will most commonly see the installation—e.g., front of porch, living room doorway. Note which direction feels “forward” (e.g., left to right across a mantel).

- Test the first loop: Wrap 3–4 inches of cord loosely around your support. Observe how the bulbs sit: Are they perpendicular to the surface? Do they nestle or lift? If bulbs tilt inward or gaps widen, reverse direction.

- Lock in consistency: Once confirmed, wrap the full strand without reversing mid-install. Use plastic clips—not staples or nails—to secure every 12–18 inches. Apply light downward pressure as you go to encourage bulb alignment.

- Final verification: Step back 6 feet. Scan slowly left to right. Coverage should appear rhythmically even—not perfectly uniform (natural variation is expected), but without rhythmic thinning or bulging. If you spot a pattern of irregularity, isolate the nearest 2–3 loops and rewrap that segment only.

“Directional wrapping is the silent foundation of professional lighting. Get it wrong, and no amount of extra bulbs or higher wattage compensates. Get it right, and even economy-grade strings perform like premium ones.” — Derek Lin, Master Installer & Lead Educator, Holiday Lighting Institute

FAQ

Does the direction matter for battery-operated lights?

Yes—especially for flexible wire types. Battery packs add weight at one end, making torsional imbalance more pronounced. Clockwise wrapping helps distribute that weight downward and prevents the pack from twisting the entire strand off-axis.

I’ve always wrapped counterclockwise and never had issues. Am I doing something else right?

Possibly. You may be unconsciously compensating—using tighter spacing, adding more anchor points, or selecting supports with textures that grip wire better (e.g., rough-hewn wood vs. smooth aluminum). But that compensation increases installation time and wear. Switching to clockwise wrapping often lets you reduce clip count by 20–30% while improving results.

What if my lights came pre-wrapped on a spool labeled “counterclockwise”?

Respect the manufacturer’s labeling. Some overseas producers (notably in Vietnam and India) use counterclockwise spooling as standard. Unspool fully, let rest for 60 seconds, then wrap in the direction that yields the flattest, quietest lay against your surface—regardless of label. The goal is functional alignment, not dogma.

Why Consistency Beats Intuition Every Time

Human hands are imperfect instruments. We rely on feel, habit, and visual cues—but light coverage is governed by material science. A 2022 University of Illinois materials engineering study demonstrated that repeated counterclockwise wrapping on stranded wire increases micro-fractures in copper conductors by 40% over five seasonal cycles compared to clockwise wrapping. That degradation doesn’t cause immediate failure, but it raises resistance, generates subtle heat at connection points, and accelerates insulation brittleness. More importantly, inconsistent direction across multiple strands on one structure creates competing torsional fields—so one strand pulls left while another pulls right, resulting in visible warping of the support (especially noticeable on thin railings or slender tree trunks). Professional installers don’t choose direction based on handedness or comfort. They choose it based on repeatability, longevity, and optical performance—and decades of field data confirm clockwise delivers superior outcomes across 92% of common residential applications in North America and Western Europe.

Conclusion

Wrapping lights isn’t ritual—it’s precision work disguised as tradition. The choice between clockwise and counterclockwise isn’t about superstition or muscle memory. It’s about honoring the physical intelligence embedded in every foot of wire: its torsional memory, its connector architecture, its thermal behavior, and its relationship to gravity and surface contact. When you wrap clockwise—mindfully, consistently, and with attention to bulb orientation—you’re not just hanging lights. You’re engineering visibility. You’re extending product life. You’re turning seasonal decoration into a repeatable, scalable practice grounded in observable cause and effect. This season, pause before the first loop. Test both directions on a small section. Feel the difference in resistance, observe the change in bulb angle, measure the gap consistency. Then commit—not out of habit, but out of understanding. Your lights—and your future self, untangling next November—will thank you.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?