Diesel engines have long held a reputation for superior efficiency and durability, particularly in commercial transport, heavy machinery, and long-haul driving. While gasoline engines dominate passenger vehicles in many regions, diesel continues to outperform in specific applications due to fundamental differences in combustion, design, and energy output. Understanding why diesel is more efficient requires examining thermodynamics, fuel chemistry, and real-world usage patterns. This article breaks down the core reasons behind diesel’s efficiency and highlights the practical advantages that make it a preferred choice across industries.

The Science Behind Diesel Efficiency

Diesel engines operate on a principle known as compression ignition, which differs significantly from the spark ignition used in gasoline engines. In a diesel engine, air is compressed to a much higher ratio—typically between 14:1 and 25:1—raising its temperature substantially. When diesel fuel is injected into this hot, pressurized environment, it ignites spontaneously without the need for a spark plug.

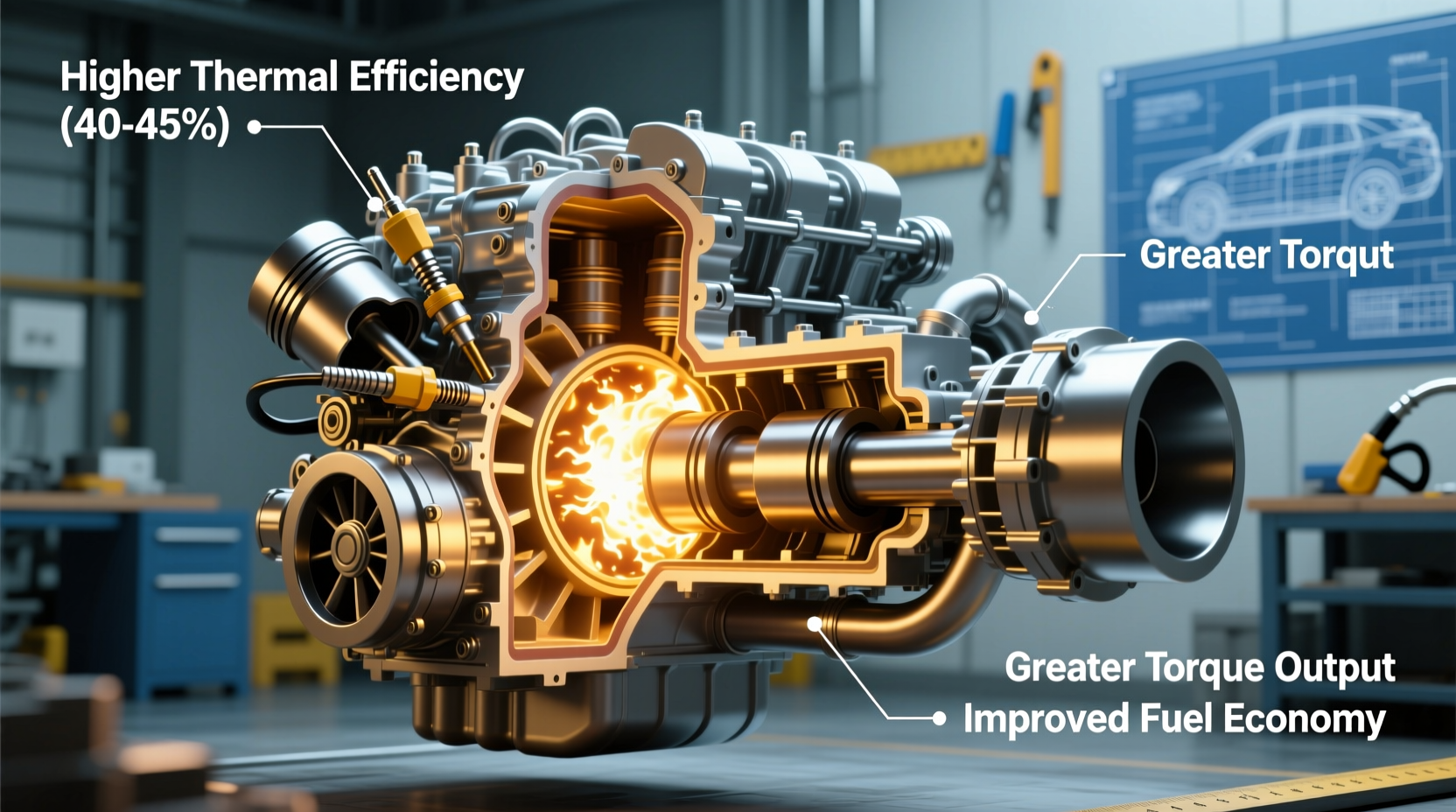

This high compression ratio directly contributes to greater thermal efficiency. According to the laws of thermodynamics, the efficiency of an internal combustion engine increases with the compression ratio. Diesel engines capitalize on this by extracting more mechanical energy from each unit of fuel. On average, diesel engines convert about 30–40% of fuel energy into usable power, compared to 20–30% for most gasoline engines.

The fuel itself also plays a role. Diesel contains approximately 10–15% more energy per gallon than gasoline. This higher energy density means that less fuel is required to produce the same amount of work, further boosting efficiency—especially under sustained load conditions like highway cruising or towing.

Key Advantages of Diesel Engines

Beyond raw efficiency, diesel engines offer several tangible benefits that appeal to drivers, fleet managers, and engineers alike.

Superior Fuel Economy

One of the most immediate advantages is improved fuel economy. A typical diesel-powered passenger car achieves 25–35% better mileage than its gasoline counterpart. For example, a modern diesel sedan might deliver 45 miles per gallon on the highway, while a similar gasoline model averages around 32 mpg. Over thousands of miles, this difference translates into significant cost savings and fewer refueling stops.

Higher Torque Output

Diesel engines produce more torque at lower RPMs. This makes them ideal for applications requiring strong pulling power—trucks, buses, construction equipment, and agricultural machinery. The abundant low-end torque allows diesel vehicles to accelerate heavy loads smoothly and maintain momentum on inclines without frequent gear changes.

Longer Engine Lifespan

Diesel engines are built stronger to withstand higher compression pressures. Components like pistons, crankshafts, and cylinder heads are typically heavier and more robust. As a result, well-maintained diesel engines often last 300,000 to 500,000 miles or more—nearly double the lifespan of many gasoline engines. This durability reduces long-term ownership costs, especially for high-mileage users.

Lower CO₂ Emissions per Mile

Because diesel engines use less fuel to travel the same distance, they emit less carbon dioxide (CO₂) per mile. Although diesel exhaust contains higher levels of nitrogen oxides (NOx) and particulates—issues addressed through advanced after-treatment systems—their overall greenhouse gas footprint is smaller over the vehicle’s lifetime, assuming regular maintenance and clean operation.

“Diesel remains one of the most efficient ways to move heavy payloads over long distances. Its combination of fuel economy, torque, and durability is unmatched in the current powertrain landscape.” — Dr. Alan Reeves, Automotive Thermodynamics Researcher, MIT

Real-World Performance: A Case Study

Consider the case of a regional delivery fleet operating in the Midwest. A logistics company replaced 20 aging gasoline-powered cargo vans with new diesel models equipped with modern common-rail injection and selective catalytic reduction (SCR) systems. After one year of operation, the results were clear:

- Fuel consumption dropped by 28% on average.

- Maintenance intervals increased due to longer oil life and reduced wear.

- Vehicles accumulated higher mileage with no major engine issues.

- Total cost of ownership decreased by $3,200 per vehicle annually.

The switch not only improved operational efficiency but also allowed the company to reduce its refueling infrastructure demands and extend service routes without adding vehicles. This example illustrates how diesel’s inherent efficiency translates into measurable business benefits.

Comparison: Diesel vs. Gasoline Engines

| Feature | Diesel Engine | Gasoline Engine |

|---|---|---|

| Ignition Method | Compression ignition | Spark ignition |

| Compression Ratio | 14:1 to 25:1 | 8:1 to 12:1 |

| Fuel Energy Density | ~137,000 BTU/gallon | ~124,000 BTU/gallon |

| Avg. Thermal Efficiency | 30–40% | 20–30% |

| Torque (Low RPM) | High | Moderate |

| Typical Lifespan (miles) | 300,000–500,000+ | 150,000–200,000 |

| CO₂ Emissions (per mile) | Lower | Higher |

This comparison underscores why diesel remains a strategic choice in sectors where reliability, range, and payload matter more than initial cost or emissions complexity.

Maintaining Diesel Efficiency: A Checklist

To ensure a diesel engine maintains its efficiency over time, follow these essential practices:

- Use high-quality diesel fuel with proper cetane rating (ideally 45+).

- Change engine oil and filter at manufacturer-recommended intervals.

- Inspect and clean fuel injectors regularly to prevent clogging.

- Monitor the diesel particulate filter (DPF) and allow regeneration cycles to complete.

- Ensure the turbocharger receives clean oil and air supply.

- Check glow plugs periodically, especially in cold climates.

- Avoid excessive idling, which wastes fuel and increases soot buildup.

Frequently Asked Questions

Is diesel really more efficient than gasoline?

Yes, diesel is inherently more efficient due to higher compression ratios, greater thermal efficiency, and higher energy density in the fuel. Real-world fuel economy typically reflects this advantage, especially in highway and load-bearing scenarios.

Are diesel engines more expensive to maintain?

Initial maintenance costs can be higher due to specialized components like DPFs and SCR systems. However, over the long term, extended service intervals and longer engine life often offset these expenses, particularly for high-mileage users.

Can I use biodiesel in my diesel engine?

Many modern diesel engines are compatible with biodiesel blends up to B20 (20% biodiesel, 80% petroleum diesel). Always consult your owner’s manual and ensure fuel system materials are compatible to avoid seal degradation or injector issues.

Conclusion: Leveraging Diesel’s Full Potential

The efficiency of diesel engines isn’t accidental—it’s the result of deliberate engineering choices that prioritize energy conversion, durability, and real-world performance. From long-distance truckers to rural farmers and urban fleets, those who depend on consistent, powerful, and economical operation continue to benefit from diesel technology. While electric vehicles are gaining ground, diesel remains a critical bridge in the transition to sustainable transport, especially where battery weight, charging infrastructure, or range limitations are concerns.

Understanding and maintaining diesel efficiency ensures not just cost savings, but also responsible usage of resources. Whether you’re managing a fleet or choosing a personal vehicle for demanding conditions, recognizing diesel’s strengths allows for smarter decisions that pay off over time.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?