For decades, Freon—specifically R-22 refrigerant—was a cornerstone of air conditioning and refrigeration systems across homes and industries. But today, its use is heavily restricted, and production has been largely phased out in the United States and many other countries. This shift isn’t arbitrary; it’s the result of decades of scientific research, international cooperation, and environmental policy designed to protect both the Earth’s atmosphere and public health. Understanding why Freon is regulated requires examining its chemical impact, the global response, and the practical implications for consumers and businesses alike.

The Environmental Impact of Freon

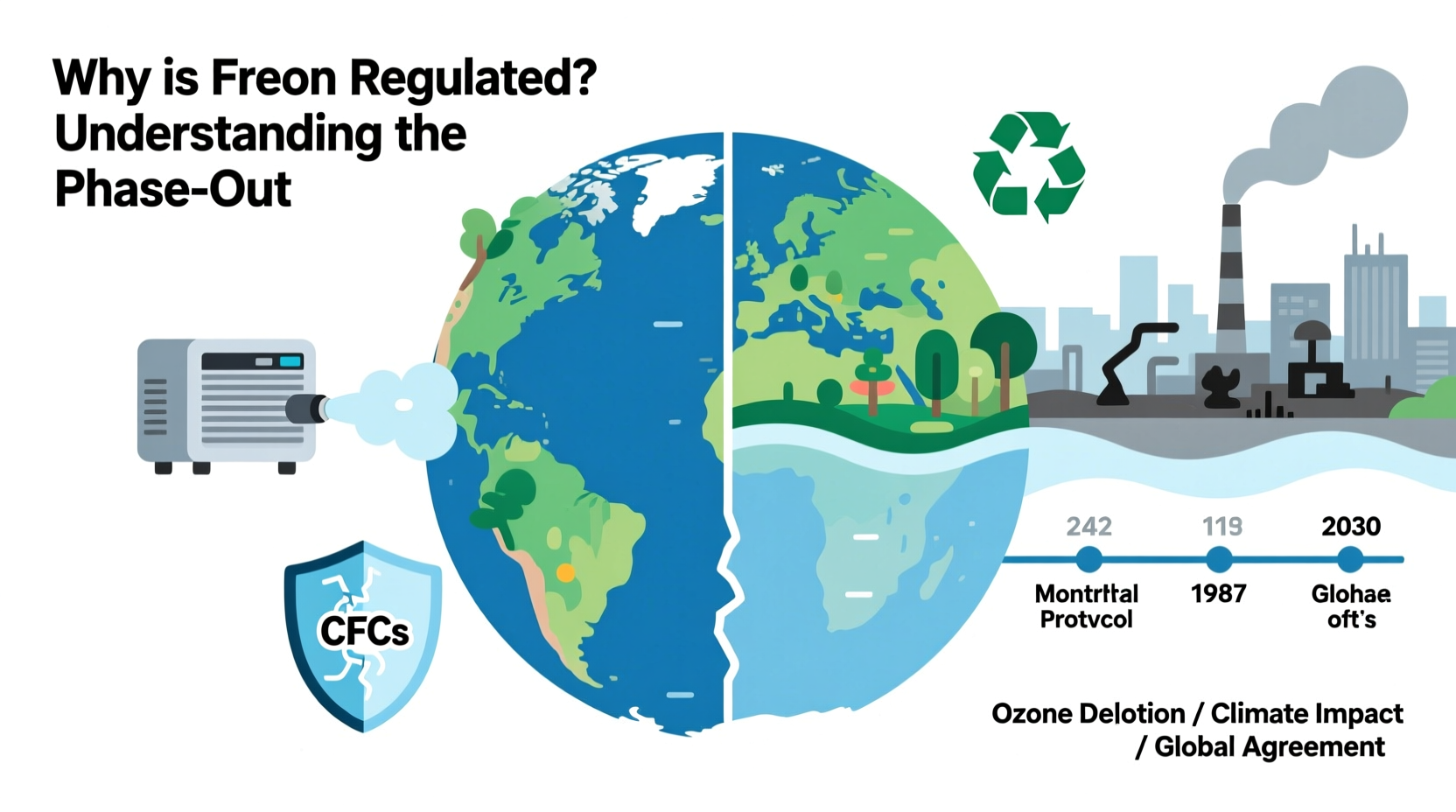

Freon, a brand name for chlorofluorocarbons (CFCs) and hydrochlorofluorocarbons (HCFCs), was widely used due to its stability and effectiveness as a refrigerant. However, this same stability allows these chemicals to persist in the lower atmosphere until they eventually rise into the stratosphere. There, ultraviolet (UV) radiation breaks them down, releasing chlorine atoms that catalytically destroy ozone molecules.

The thinning of the ozone layer increases the amount of harmful UV radiation reaching the Earth’s surface, contributing to higher rates of skin cancer, cataracts, and damage to ecosystems. In the 1980s, scientists discovered a massive seasonal \"ozone hole\" over Antarctica, directly linked to CFC emissions. This alarming finding prompted urgent global action.

“Without the Montreal Protocol, we would have faced catastrophic increases in UV radiation by mid-century.” — Dr. Stephen O. Andersen, Co-Chair of the Montreal Protocol Technology and Economic Assessment Panel

The Montreal Protocol and Global Phaseout Timeline

In 1987, the world came together to sign the Montreal Protocol on Substances that Deplete the Ozone Layer. This landmark international treaty mandated the gradual elimination of ozone-depleting substances, including HCFC-22 (R-22), commonly known as Freon. The agreement has since been ratified by all 197 United Nations member states, making it one of the most successful environmental treaties in history.

The phaseout of Freon in the U.S. followed a structured timeline under the guidance of the Environmental Protection Agency (EPA):

| Year | Milestone |

|---|---|

| 1995 | CFC production banned in developed countries |

| 2003 | HCFC-22 phaseout begins; new equipment must reduce usage |

| 2010 | Ban on manufacturing or importing R-22 for new AC units |

| 2020 | Nearly complete phaseout: production and import of R-22 prohibited |

| 2030 | Final deadline: complete elimination of all HCFCs, including stockpiled reserves |

This step-by-step approach allowed industries time to transition to safer alternatives while minimizing economic disruption.

Why HCFCs Like R-22 Were Targeted

While CFCs were the primary culprits behind ozone depletion, HCFCs like R-22 were introduced as transitional substitutes because they have lower ozone depletion potential (ODP). However, they still contain chlorine and contribute to ozone breakdown, albeit at a reduced rate. Additionally, HCFCs are potent greenhouse gases with high global warming potential (GWP), meaning they trap heat in the atmosphere far more effectively than carbon dioxide.

R-22 has a GWP of about 1,810—meaning one pound of R-22 traps as much heat as 1,810 pounds of CO₂ over 100 years. Given the scale of HVAC systems globally, even limited emissions contribute significantly to climate change. Phasing out R-22 thus serves dual environmental goals: protecting the ozone layer and mitigating climate change.

Modern Alternatives to Freon

Today’s refrigerants are designed to be more environmentally responsible without sacrificing performance. Common replacements include:

- R-410A (Puron): A non-ozone-depleting HFC refrigerant widely adopted in residential HVAC systems. Though it has zero ODP, it still has high GWP (~2,088).

- R-32: Used increasingly in Asia and Europe, it has one-third the GWP of R-410A and improved energy efficiency.

- R-454B and R-290 (propane): Emerging low-GWP options with excellent thermodynamic properties, though flammability requires careful handling.

Manufacturers like Carrier, Trane, and Lennox now produce systems specifically engineered for these next-generation refrigerants, offering better efficiency and compliance with current regulations.

What the Phaseout Means for Homeowners and Businesses

For those with older HVAC systems installed before 2010, the Freon phaseout has real-world consequences. As R-22 becomes scarcer, its price has skyrocketed—from around $5 per pound in 2010 to over $30–$50 per pound today in some markets. Repairs involving refrigerant recharge can now cost hundreds or even thousands of dollars.

Moreover, EPA regulations prohibit the venting of R-22 during servicing. Only certified technicians may handle it, adding to labor costs and complexity. Eventually, maintaining an R-22 system will become impractical due to lack of supply and support.

Mini Case Study: The Johnson Family’s AC Upgrade

The Johnsons in Phoenix, Arizona, had a 15-year-old central AC unit that relied on R-22. Last summer, their system developed a refrigerant leak. A repair quote included $800 just for 3 pounds of R-22, plus $400 in labor. Faced with recurring issues and rising cooling bills, they opted to replace the unit with a new R-410A-compatible model. Although the upfront cost was $4,500, their energy bills dropped by 28% in the first month, and they qualified for a $600 utility rebate. Within five years, they expect to break even—plus gain reliability and comfort.

Action Plan: Navigating the Freon Phaseout

If you're affected by the Freon phaseout, follow this step-by-step guide to make informed decisions:

- Determine your system’s refrigerant type. Check the label on your outdoor condenser unit or consult installation records.

- Schedule a professional inspection. A licensed HVAC technician can assess system age, efficiency, and refrigerant condition.

- Evaluate repair vs. replacement. If your system is over 10 years old or uses R-22, replacement is often more economical long-term.

- Research modern, eco-friendly models. Look for ENERGY STAR-rated units using R-410A, R-32, or other low-GWP refrigerants.

- Explore rebates and incentives. Many utilities and governments offer discounts for upgrading to efficient, compliant systems.

Checklist: Preparing for a Post-Freon HVAC System

- ☑ Confirm whether your current system uses R-22

- ☑ Monitor for signs of refrigerant leaks (reduced cooling, hissing sounds, ice buildup)

- ☑ Get maintenance from EPA Section 608-certified technicians

- ☑ Budget for eventual system replacement

- ☑ Research available tax credits or utility rebates

- ☑ Consider smart thermostats to maximize efficiency with new units

Frequently Asked Questions

Can I still buy R-22 for my old AC unit?

Yes, but only reclaimed or recycled R-22 is legally available since new production ceased in 2020. Supply is limited and prices are high. Availability varies by region and supplier.

Is it illegal to use an R-22 system?

No. You can continue using an existing R-22 system. However, servicing it is restricted to certified professionals, and future repairs may be cost-prohibitive due to refrigerant scarcity.

Are newer refrigerants safe?

Yes. Modern refrigerants like R-410A and R-32 undergo rigorous safety testing. While some, like R-290, are mildly flammable, they are used in sealed systems with strict installation standards to ensure safety.

Conclusion: A Sustainable Future Beyond Freon

The regulation and phaseout of Freon represent a pivotal achievement in environmental protection. What began as a response to a growing ozone crisis has evolved into a broader movement toward sustainable refrigeration technologies. The science is clear, the policies are in place, and the alternatives are viable. For homeowners and businesses, the transition may require investment, but it brings long-term benefits: lower operating costs, improved efficiency, and a smaller environmental footprint.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?