If you're investing time and effort into 3D printing only to face repeated nozzle clogs, you're not alone. This frustrating issue disrupts print jobs, wastes filament, and can damage your printer over time. While occasional clogs may be expected, consistent blockages signal underlying problems that need diagnosis and correction. Understanding why your 3D printer nozzle keeps clogging is the first step toward reliable, high-quality output. From filament quality and temperature settings to mechanical wear and maintenance habits, multiple factors contribute to this persistent problem. Addressing them systematically can transform your printing experience from chaotic to seamless.

Understanding Nozzle Clogs: Types and Symptoms

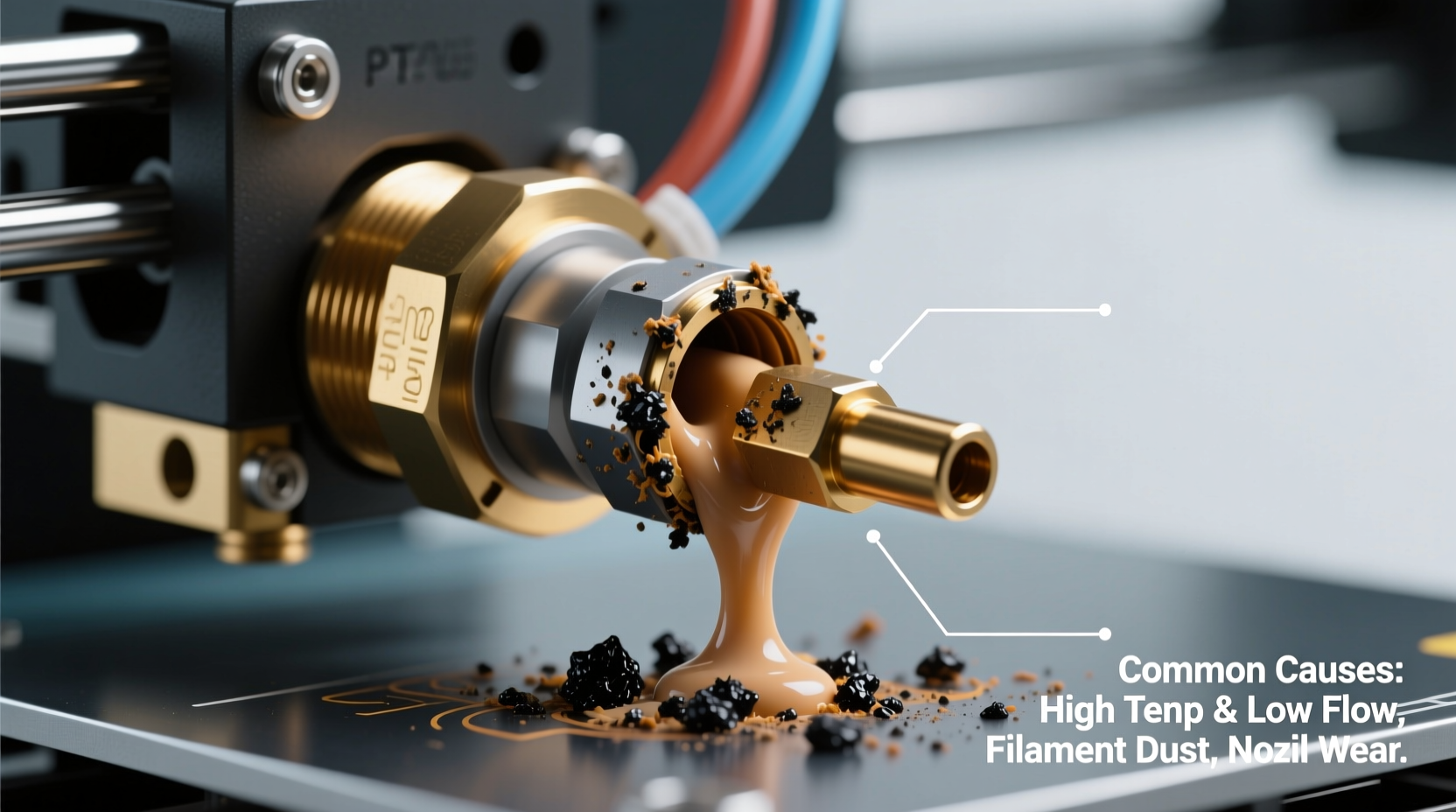

Nozzle clogs aren’t always total blockages. They can manifest in subtle ways that degrade print quality before fully stopping extrusion. Recognizing the types helps identify root causes:

- Partial clogs: Reduced filament flow, inconsistent layer lines, under-extrusion, or stringing.

- Full clogs: Complete stoppage of filament extrusion, clicking sounds from the extruder gear slipping.

- Heat creep: Filament softens too early in the hotend and jams above the melt zone.

- Carbonized buildup: Burnt filament residue accumulates inside the nozzle after prolonged high-temperature use.

Each type points to different issues—mechanical, thermal, or material-related. Ignoring early signs often leads to worsening performance and more frequent interventions.

Common Causes of Consistent Nozzle Clogs

1. Poor Filament Quality or Contamination

Inexpensive or improperly stored filament absorbs moisture from the air, especially hygroscopic materials like PLA, PETG, and nylon. Wet filament creates steam when heated, causing bubbles, sputtering, and internal carbon deposits that lead to clogs.

Filament with inconsistent diameter forces the extruder to adjust constantly, increasing stress on the feeding system. Debris such as dust or spool labels caught in the filament path can also jam the nozzle.

2. Incorrect Printing Temperatures

Running the nozzle too cold prevents proper melting, leading to under-extrusion and gradual buildup. Conversely, excessively high temperatures cause filament to degrade and carbonize inside the hotend, especially if left idle at high heat.

Different filaments require precise temperature ranges. For example:

- PLA: 190–220°C

- PETG: 220–250°C

- ABS: 230–260°C

- Nylon: 240–280°C

“Temperature stability is critical. Even 10 degrees off can change how cleanly a filament melts and flows through the nozzle.” — Daniel Reyes, 3D Printer Technician & MakerSpace Lead

3. Heat Creep Due to Cooling Issues

Heat creep occurs when heat from the hotend travels upward into the cold end, softening filament prematurely. This is often due to a failing heatsink fan or blocked cooling fins. When filament softens outside the intended melt zone, the extruder can’t push it down effectively, causing jams.

This is especially common with direct-drive setups and high-speed printing where heat dissipation is crucial.

4. Worn or Low-Quality Nozzles

Standard brass nozzles wear out faster when printing abrasive filaments like glow-in-the-dark PLA, carbon fiber, or metal-filled composites. As the inner bore erodes, material builds up unevenly, creating flow restrictions.

Using a worn nozzle increases the risk of internal ridges catching molten plastic, promoting clogs over time.

5. Infrequent Maintenance and Residue Buildup

Over time, degraded filament and color mixing leave behind residues. Without regular cleaning, these form hardened layers inside the nozzle and throat. Skipping routine maintenance turns minor buildup into chronic clogs.

Step-by-Step Guide to Diagnose and Fix Nozzle Clogs

Follow this systematic approach to identify and resolve the source of recurring clogs:- Check filament condition: Inspect for moisture (listen for popping sounds during printing), kinks, or debris. Store filament in sealed containers with desiccants.

- Verify temperature settings: Confirm you’re using manufacturer-recommended temps. Use a calibration tower to test optimal extrusion across a range.

- Inspect cooling systems: Ensure the heatsink fan runs continuously during printing. Clean dust from fins and check for obstructions.

- Perform a cold pull (atomic pull): Heat the nozzle to printing temp, then cool to 90–100°C. Pull out the filament sharply to remove internal debris.

- Disassemble and clean the hotend: Remove the nozzle and use a needle or ultrasonic cleaner to clear blockages. Replace if pitted or worn.

- Upgrade components if needed: Switch to a hardened steel nozzle for abrasive filaments or install an all-metal hotend for better heat resistance.

Prevention Checklist: Avoid Future Clogs

Use this actionable checklist to minimize the risk of recurring nozzle issues:- ✅ Store all filament in airtight bins with silica gel packs.

- ✅ Calibrate extruder steps/mm and flow rate monthly.

- ✅ Print temperature towers when switching filament brands or colors.

- ✅ Run a cold pull every 10–15 hours of print time.

- ✅ Keep the PTFE tube (if present) trimmed correctly and replace if frayed or discolored.

- ✅ Upgrade to a high-temp throat liner if printing above 240°C regularly.

- ✅ Monitor hotend cooling fan operation—replace if noisy or slow.

- ✅ Use reputable filament brands with consistent diameter tolerances.

Real-World Example: The Case of the Recurring PETG Clog

Jamal, a product designer running a small prototyping studio, faced daily interruptions due to nozzle clogs while printing PETG enclosures. Despite cleaning attempts, the issue returned within hours. He assumed it was a faulty spool—until he reviewed his workflow.

He discovered three contributing factors: his garage workspace had high humidity, he was storing filament on open shelves; he used a standard brass nozzle; and his hotend fan was partially clogged with dust. After sealing his filament in dry boxes, installing a hardened steel nozzle, and cleaning the heatsink, clogs dropped from daily to once every few weeks. A simple maintenance schedule reduced downtime by over 80%.

His experience underscores that consistent clogs are rarely due to one single flaw—but rather a chain of overlooked details.

Do’s and Don’ts: Best Practices for Nozzle Longevity

| Do’s | Don’ts |

|---|---|

| Use filtered compressed air to blow out the nozzle after disassembly | Don’t leave filament loaded in the hotend when powered off for long periods |

| Run a retraction test print monthly to detect early flow issues | Don’t exceed recommended printing temperatures “to improve flow” |

| Replace PTFE tubes every 3–6 months if printing frequently | Don’t use metal tools to poke the nozzle while hot—use a brass needle |

| Label nozzles by material type (e.g., “PETG Only”) to avoid cross-contamination | Don’t ignore clicking sounds from the extruder motor |

| Keep a log of nozzle usage hours for timely replacement | Don’t mix abrasive and non-abrasive filaments without purging |

Frequently Asked Questions

How often should I replace my 3D printer nozzle?

For standard brass nozzles used with non-abrasive filaments like PLA or ABS, replacement every 3–6 months with regular use is advisable. If printing abrasive materials, consider replacing every 1–2 months or switching to hardened steel nozzles, which last significantly longer.

Can I fix a clogged nozzle without removing it?

Sometimes. A cold pull (also called atomic pull) can clear minor blockages without disassembly. Heat the hotend to normal printing temperature, load a piece of flexible filament like nylon or PETG, then cool to around 90°C and pull firmly. Repeat until debris comes out. For severe clogs, physical removal and deep cleaning are necessary.

Why does my nozzle clog only when I switch colors?

Color changes often trap old filament or create mixed-material residues that degrade at different temperatures. Incomplete purging leaves behind material that hardens during cooldown. Always perform a thorough purge with a cleaning filament or matching base material when switching colors, especially between chemically different types (e.g., PLA to ABS).

Conclusion: Turn Frustration into Reliable Prints

Consistent nozzle clogs are not inevitable—they’re signals. Your printer is communicating that something in the system needs attention, whether it’s filament storage, hardware condition, or process consistency. By approaching the issue methodically, applying preventive maintenance, and upgrading components where appropriate, you can achieve smooth, uninterrupted printing sessions. The key is vigilance: monitor performance, act early on warning signs, and treat your printer as a precision tool that thrives on care.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?