Bread baking is as much a science as it is an art. When your dough fails to rise, it can feel like the entire process has collapsed—literally. But before you discard that lifeless lump of flour and water, understand that most failed rises are fixable. The reasons behind sluggish or non-rising dough range from inactive yeast to incorrect temperature, improper hydration, or even ingredient imbalances. With a clear understanding of what went wrong and a few strategic interventions, you can often revive your dough and still pull a golden, airy loaf from the oven.

Understanding the Science of Dough Rise

Dough rises because of fermentation—a biological process driven by yeast. When active dry or fresh yeast is mixed with warm water and food (typically sugar or starch in flour), it metabolizes those sugars and releases carbon dioxide gas. This gas gets trapped in the gluten network formed during kneading, causing the dough to expand. For this process to work efficiently, several conditions must be met: viable yeast, proper temperature, sufficient time, and balanced ingredients.

If any one of these factors is off, the fermentation slows or stops altogether. A dough that doesn’t rise isn’t always a lost cause. Often, it’s simply dormant rather than dead. Recognizing the difference between inactive and irreversibly failed dough is the first step toward rescue.

“Yeast is resilient but sensitive. It thrives in a narrow window of warmth and nourishment. Most ‘failed’ doughs just need a second chance under better conditions.” — Dr. Elena Ruiz, Food Microbiologist and Fermentation Specialist

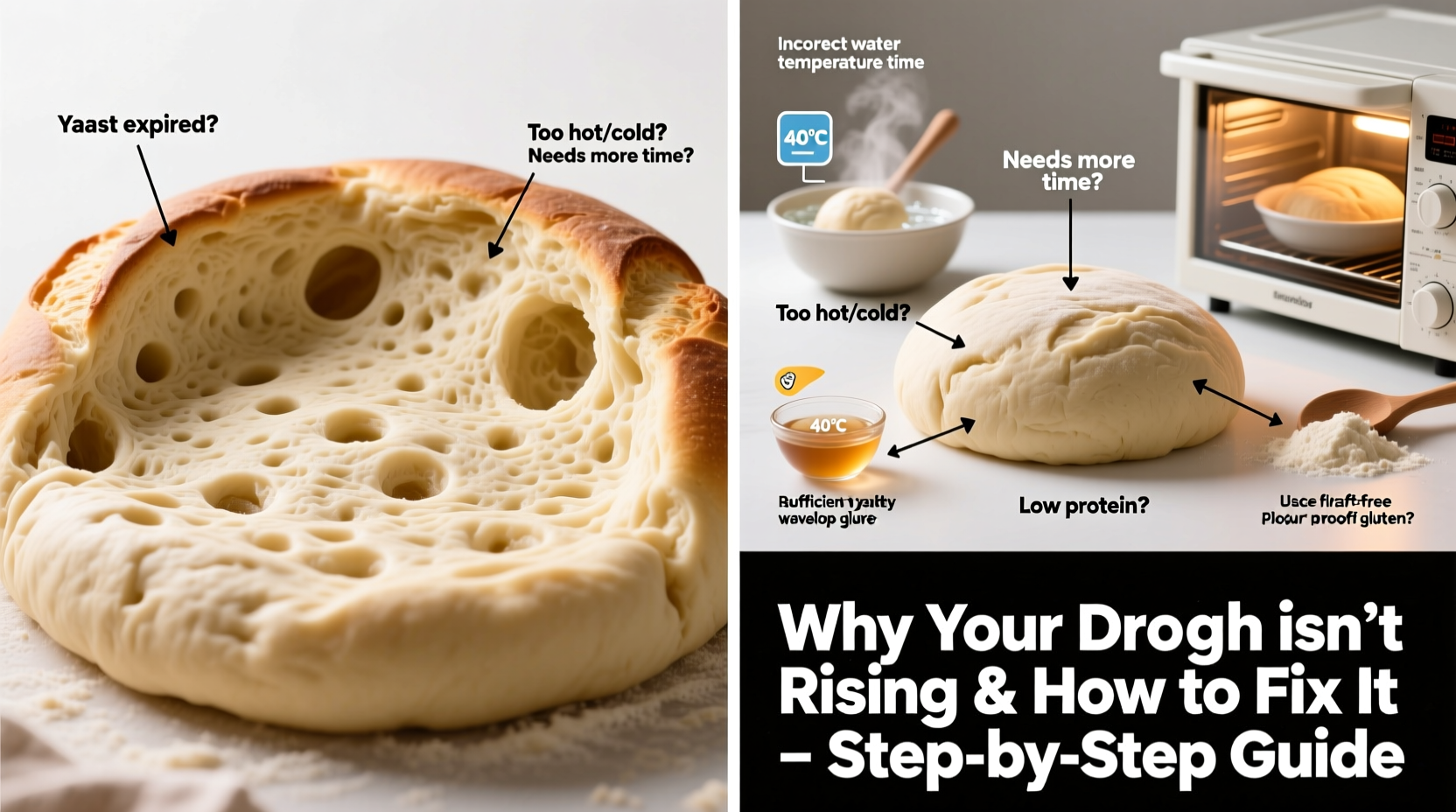

Common Reasons Why Bread Dough Won’t Rise

Before attempting a rescue, diagnose the root cause. Treating symptoms without addressing the underlying issue rarely works. Below are the most frequent culprits behind flat dough.

1. Inactive or Dead Yeast

Yeast is a living organism. If it’s old, improperly stored, or exposed to extreme temperatures during mixing, it may not activate. Using boiling water when dissolving yeast kills it instantly. Conversely, water below 95°F (35°C) may not wake it up effectively.

2. Cold Environment

Fermentation slows dramatically in cold temperatures. A drafty kitchen, chilly countertop, or winter ambient air can stall rising completely. Yeast works best between 75°F and 85°F (24–29°C).

3. Excess Salt or Fat

Salt controls yeast activity. While necessary for flavor and structure, too much salt (more than 2% of flour weight) can inhibit or kill yeast. Similarly, high-fat doughs like brioche require longer rise times because fat coats yeast cells, slowing their metabolism.

4. Poor Gluten Development

If the dough hasn’t been kneaded enough—or if low-protein flour was used—the gluten matrix won’t form properly. Without this elastic structure, gas escapes instead of being trapped, preventing expansion.

5. Overhydration or Underhydration

Too much water weakens the gluten network; too little restricts yeast mobility and gas retention. Ideal hydration varies by flour type but generally falls between 60–75% of flour weight in water.

6. Old or Improperly Stored Flour

Flour loses enzymatic activity over time, especially if exposed to moisture or pests. Stale flour provides less food for yeast, resulting in poor fermentation.

Step-by-Step Guide to Diagnose and Rescue Flat Dough

Not all hope is lost when your dough sits stubbornly still. Follow this timeline-based approach to assess and potentially revive it.

- Wait Patiently (0–2 Hours): Sometimes, especially in cooler kitchens, rising takes longer. Give the dough at least two hours in a warm spot before declaring failure.

- Check for Signs of Life: Look for tiny bubbles on the surface or along the bowl’s edge. Gently press a finger into the dough—if it slowly springs back, fermentation may be underway.

- Create a Warm Proofing Environment: Place the bowl in a turned-off oven with a pan of boiling water on the rack below. Close the door. The steam and radiant heat create an ideal proofing chamber (around 80°F).

- Add Fresh Yeast (If Needed): If after 2 hours there’s no activity, mix 1/2 teaspoon active dry yeast with 1 tablespoon warm water and 1/2 teaspoon sugar. Let it foam for 5–10 minutes, then knead it into the dough.

- Knead Again Briefly: After adding fresh yeast, knead for 2–3 minutes to distribute it evenly and redevelop gluten.

- Retard in the Fridge for Slow Fermentation: If immediate revival fails, place the dough in the refrigerator for 8–12 hours. Cold fermentation allows natural enzymes and residual yeast to work slowly, often producing better flavor and some volume.

- Shape and Bake as Flatbread (Last Resort): If the dough still won’t rise, roll it thin and bake as focaccia, pizza, or crackers. You’ll salvage texture and flavor even without loft.

Do’s and Don’ts: Table of Best Practices

| Do’s | Don’ts |

|---|---|

| Use water between 105°F and 115°F to activate yeast | Use boiling or ice-cold water with yeast |

| Store yeast in the freezer for long-term viability | Leave yeast in a humid pantry for months |

| Proof yeast before mixing into flour | Assume expired yeast will still work |

| Place dough in a lightly oiled bowl, covered with a damp cloth | Leave dough exposed to dry air |

| Use a digital thermometer to check water and room temperature | Rely solely on touch to judge water warmth |

| Measure salt precisely—usually 1.8–2% of flour weight | Double the salt for taste without adjusting yeast time |

Real Example: Rescuing a Holiday Sourdough That Wouldn’t Rise

Sarah, a home baker in Vermont, prepared a sourdough boule for Thanksgiving dinner. She fed her starter the night before and mixed the dough early in the morning. By evening, however, the dough hadn’t risen. The house was cold—only 64°F—and the kitchen had no heating vent.

Instead of starting over, Sarah placed the bowl inside her oven with a bowl of steaming water. She repeated this every 45 minutes, maintaining a stable 78°F environment. After three hours, the dough had doubled. She shaped it, did a final proof, and baked it. The result? A crackling crust and open crumb that impressed her guests.

Her mistake wasn’t technique—it was environment. Her rescue method addressed the core issue: temperature. This case illustrates how external conditions often matter more than recipe precision.

Checklist: How to Prevent Dough From Failing to Rise

- ✅ Check yeast expiration date before use

- ✅ Proof yeast in warm water with sugar to confirm activity

- ✅ Use a thermometer to verify water temperature

- ✅ Mix salt separately or add it after initial yeast activation

- ✅ Knead until dough passes the “windowpane test” (stretch a small piece thin enough to see light through without tearing)

- ✅ Place dough in a warm, draft-free area (ideal: 75–85°F)

- ✅ Cover dough to prevent skin formation

- ✅ Allow sufficient time—some whole-grain or rye doughs take 3+ hours to rise

- ✅ Consider using a proofing box, microwave with hot water, or oven light for warmth

- ✅ Label and date your flour and yeast containers

FAQ: Common Questions About Dough That Won’t Rise

Can I still bake bread if the dough didn’t rise at all?

Yes, but don’t expect a light loaf. Flat, dense bread like Irish soda bread or certain flatbreads can result. Roll the dough thin and bake it as a pizza base or crackers. Add herbs and olive oil for flavor. It won’t be airy, but it will be edible and tasty.

How long should dough take to rise?

Most standard white doughs rise in 1–2 hours at 75–80°F. Whole grain, sourdough, or refrigerated doughs can take 4–12 hours. Cooler temperatures slow fermentation; warmer ones accelerate it. Use visual cues—doubled in size, puffy, jiggly—over strict timing.

Can I add more yeast after the dough is mixed?

Yes. Rehydrate 1/2 to 1 teaspoon of fresh yeast in warm water with sugar, let it foam, then knead it into the dough. This works best within the first few hours of the rise. After that, gluten may degrade, and acidity could inhibit new yeast.

When to Accept Failure and Start Over

Some situations are beyond rescue. If your dough smells sharply acidic, alcoholic, or rotten, it’s likely over-fermented or contaminated. If it’s been sitting out for over 12 hours in warm conditions, bacteria may have overtaken the culture. Similarly, dough made with rancid flour or completely dead yeast cannot be revived.

In these cases, compost the dough and begin again. Note what went wrong: Was the yeast expired? Was the kitchen too cold? Did you forget the yeast entirely? Every failed batch teaches something valuable.

Conclusion: Turn Failure Into Flavor

A dough that refuses to rise isn’t necessarily a loss. More often than not, it’s a signal—telling you about your environment, ingredients, or technique. With careful diagnosis and patient intervention, you can frequently bring it back to life. Even when revival isn’t possible, creative repurposing ensures nothing goes to waste.

Bread baking rewards observation, adaptability, and persistence. The next time your dough sits motionless on the counter, don’t despair. Assess, adjust, and act. Whether you end up with a lofty sourdough or a crisp rosemary flatbread, you’ve still succeeded in creating something real, handmade, and nourishing.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?