A dryer that runs smoothly during the cool cycle but starts thumping as soon as the heat kicks in can be both puzzling and concerning. Unlike constant mechanical noises, this intermittent issue suggests a problem tied specifically to thermal expansion or heat-related component behavior. While it might seem minor at first, ignoring such symptoms can lead to more serious damage—or even fire hazards in extreme cases. Understanding the root causes, recognizing warning signs, and knowing how to respond can save time, money, and ensure your appliance continues operating safely.

This article breaks down the most likely reasons behind heat-triggered thumping, walks through diagnostic steps, and provides practical repair guidance—all based on real-world technician insights and homeowner experiences.

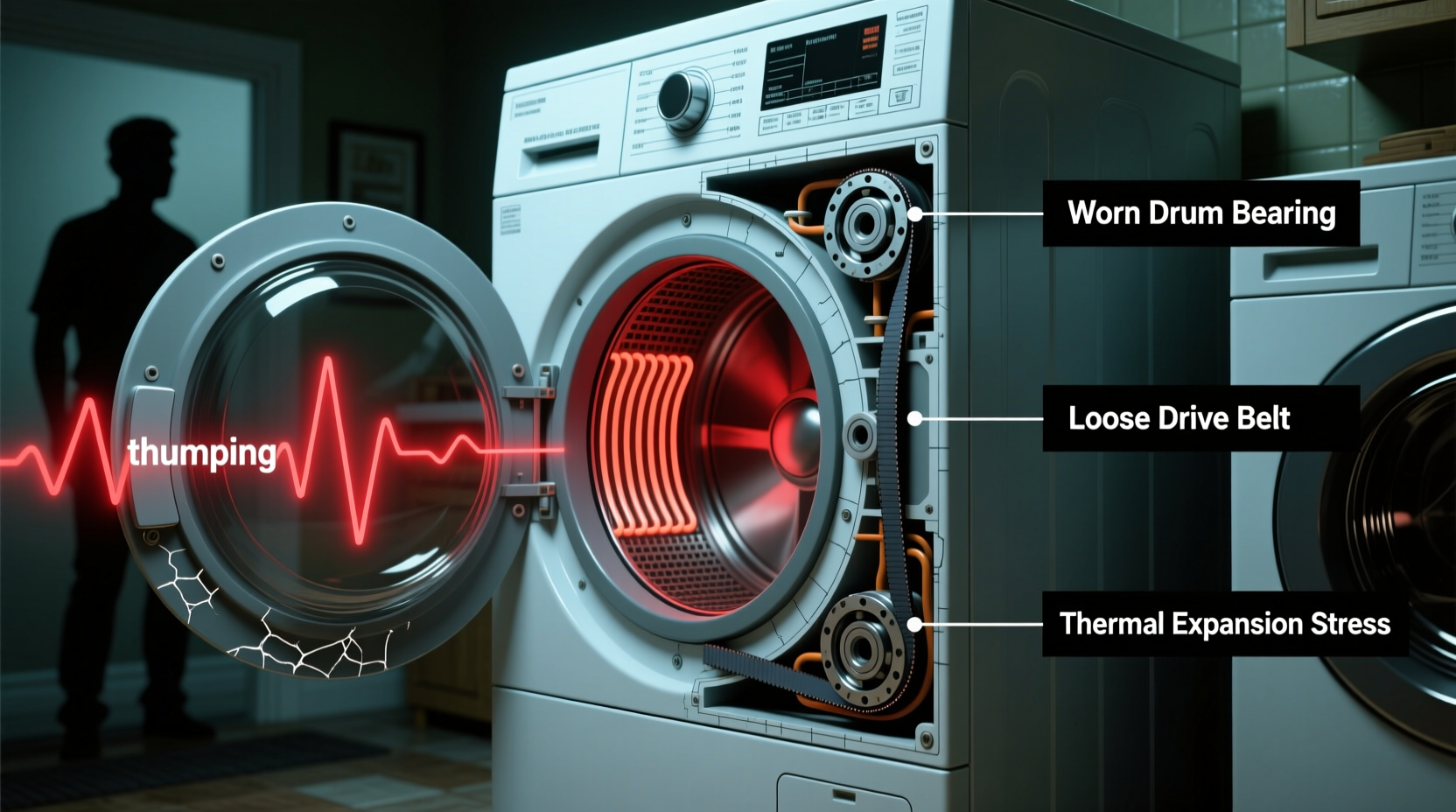

How Heat Affects Dryer Components

Dryers are engineered to handle high temperatures, but repeated heating and cooling cycles cause materials to expand and contract. Over time, this stress impacts various internal parts. When a thumping noise occurs only when the dryer heats up, the issue is often related to components that shift, warp, or loosen under thermal load.

Common materials affected include metal drum supports, plastic rollers, rubber seals, and mounting brackets. As these parts age, their tolerance for expansion diminishes. What once operated silently may begin to rub, vibrate, or knock against adjacent surfaces when heated.

For example, a slightly misaligned drum may rotate smoothly when cold but expand just enough when hot to contact the housing. Similarly, worn support rollers may develop flat spots that only become problematic under heat-induced softening of rubber compounds.

“Thermal expansion is often overlooked in appliance diagnostics. A part that seems fine at room temperature can behave completely differently at 150°F.” — Daniel Reyes, Senior Appliance Engineer at Midwest Home Systems

Top 5 Causes of Heat-Activated Thumping Noises

The following issues are the most frequent culprits behind thumping sounds that appear exclusively during the heating phase of a drying cycle.

1. Worn or Warped Drum Support Rollers

Dryer drums are supported by small roller wheels made of rubber over plastic or solid polymer. These rollers degrade over time, especially when exposed to sustained heat. As they wear, they may develop flat spots or lose roundness. When cold, the deformation might not cause noticeable vibration. But once heated, the rubber softens, amplifying imbalances and creating rhythmic thumps with each rotation.

2. Loose or Expanding Drum Glides

Front and rear drum glides (also called skates) are small pads—usually made of nylon or Teflon—that allow the drum to spin smoothly. Over time, these wear down or crack. When heated, degraded glides may expand unevenly or shift position, causing the drum to wobble and strike nearby components.

3. Damaged Blower Wheel

The blower wheel pulls air through the dryer and exhausts it. It’s typically made of plastic and mounted on a motor shaft. Cracks or missing fins on the wheel may not disrupt balance when cold. However, heat can soften the plastic, allowing warped sections to flex and strike the housing, producing a rhythmic thump or thud.

4. Loose Heating Element or Bracket

In electric dryers, the heating element is held in place by ceramic insulators and metal brackets. If one of these brackets becomes loose or cracks, it may remain stable when cold. Once heated, however, metal expansion can cause the bracket to shift or vibrate against the ductwork, resulting in a metallic knocking sound that syncs with drum rotation.

5. Misaligned Drum or Bent Shaft

If the drum itself is slightly bent or the drive shaft has warped due to overheating, the imbalance may only manifest when components expand. This is less common but possible in older units or those that have experienced poor ventilation leading to chronic overheating.

Step-by-Step Diagnostic Process

Before disassembling your dryer, follow this logical sequence to identify the source of the noise without unnecessary effort.

- Reproduce the Noise Safely: Run an empty load using a regular cycle. Listen closely to determine if the thumping starts after heating begins (typically within 3–7 minutes).

- Check Load Distribution: Add a few towels to test if unbalanced laundry could be contributing. If the noise persists with no clothes, the issue is mechanical.

- Feel for Vibration: Place a hand lightly on the top and sides of the dryer. Increased vibration during heating indicates a structural or rotating component issue.

- Inspect Ventilation: Ensure the exhaust duct is clear. Restricted airflow can cause overheating, exacerbating component expansion.

- Unplug and Open the Dryer: Disconnect power. Remove the front or top panel (consult your model’s manual). Look for visible wear on rollers, glides, and belts.

- Manually Rotate the Drum: With the belt off, spin the drum by hand. Note any grinding, catching, or uneven resistance—especially after briefly warming components with a hairdryer to simulate operating temperature.

- Examine the Blower Housing: Access the blower wheel (usually at the rear). Check for cracks, debris, or contact marks on the housing.

Do’s and Don’ts When Troubleshooting

| Do’s | Don’ts |

|---|---|

| Unplug the dryer before inspection | Ignore persistent noises hoping they’ll go away |

| Clean lint from all internal areas, including behind the drum | Operate the dryer with panels removed |

| Replace both drum rollers at the same time—even if only one looks bad | Use generic or non-OEM replacement parts without verifying compatibility |

| Lubricate glide surfaces with silicone-based dry lubricant (if recommended) | Apply oil or WD-40 to rollers or bearings—they attract lint and degrade rubber |

| Check drum alignment by measuring gap consistency around the front seal | Force components into place; misalignment can cause premature failure |

Mini Case Study: The Case of the Expanding Roller

Janice from Columbus, Ohio, noticed her Samsung dryer began thumping during medium and high-heat cycles. The noise disappeared on air-fluff mode. She initially assumed it was a foreign object but found nothing after checking the drum and vent.

After consulting a technician forum, she decided to run the dryer with the front panel off (while unplugged between tests). She observed that the drum seemed level when cold, but after five minutes of heating, a slight wobble developed near the left-side roller.

Upon replacement of both rear drum rollers—original parts costing $28 total—the noise vanished. The old rollers appeared intact at room temperature, but close inspection revealed micro-cracks in the rubber that expanded under heat, causing asymmetrical compression and imbalance.

This case highlights how visual inspection alone isn’t always sufficient—thermal behavior must be considered.

Repair Checklist: Fixing Heat-Related Thumping

- ✅ Unplug the dryer and shut off gas supply (for gas models)

- ✅ Remove front or top panel per manufacturer instructions

- ✅ Disconnect the drive belt and manually rotate the drum

- ✅ Inspect drum support rollers for flat spots, cracking, or hardening

- ✅ Examine front and rear drum glides for wear or breakage

- ✅ Check blower wheel for cracks or imbalance (remove and inspect if necessary)

- ✅ Inspect heating element brackets and mounting hardware for looseness

- ✅ Clean all lint buildup around motor, blower, and ducts

- ✅ Replace worn parts with OEM-equivalent components

- ✅ Reassemble carefully, ensuring belt tension and drum alignment are correct

- ✅ Test run using a timed heat cycle with no clothing

When to Call a Professional

While many repairs are DIY-friendly, certain situations warrant professional help:

- The heating element shows signs of arcing or melted insulation.

- You suspect a cracked blower housing or damaged motor mount.

- The drum appears visibly bent or cannot be rotated smoothly after reassembly.

- You’re uncomfortable working with electrical connections or gas lines.

According to the U.S. Consumer Product Safety Commission, faulty dryers account for nearly 15,000 home fires annually. Many stem from ignored noises, blocked vents, or improper repairs. A certified technician can perform a full safety inspection and ensure compliance with local codes.

Frequently Asked Questions

Can a clogged dryer vent cause a thumping noise?

Indirectly, yes. A blocked vent forces the dryer to overheat, increasing thermal stress on internal components. This can accelerate wear on rollers, glides, and mounts, potentially triggering noise only under heat. However, a clog alone won’t produce a rhythmic thump—it’s more likely to cause a steady hum or strain sound.

Why does my dryer thump only on heavy-duty cycles?

Heavy-duty cycles use higher heat and longer durations, intensifying thermal expansion. If components are already near failure, the added stress reveals the issue. Additionally, heavier loads increase mechanical strain, compounding the effect of weakened supports.

Is it safe to keep using my dryer if it thumps when heating?

Short-term use may be acceptable, but continued operation risks further damage. A failing roller or glide can seize, damaging the drum or motor. In rare cases, a loose heating element can short-circuit. If the noise persists beyond one or two cycles, discontinue use until repaired.

Preventive Maintenance Tips

Extending the life of your dryer and avoiding heat-related noises starts with consistent care:

- Clean the lint filter after every use. A clogged filter reduces airflow and increases internal temperatures.

- Inspect the exhaust duct annually. Remove kinks, crushes, or lint buildup in the vent line.

- Vacuum inside the dryer cabinet every 6–12 months. Use a crevice tool to reach behind the drum and around the blower.

- Avoid overloading. Heavy loads strain bearings and mounts, accelerating wear.

- Level the dryer properly. Uneven flooring causes misalignment, worsening vibration when heated.

Conclusion: Act Before the Problem Escalates

A thumping dryer that only acts up when heating is sending a clear signal: internal components are degrading under thermal stress. While the cause may seem mysterious, the solutions are often straightforward—replacing worn rollers, glides, or securing loose hardware can restore quiet operation. Ignoring the noise risks costly breakdowns or safety hazards down the line.

By applying systematic diagnostics, adhering to best practices, and performing timely maintenance, you can extend your dryer’s lifespan and maintain peace in your laundry routine. Whether you tackle the repair yourself or call in a pro, don’t delay. Address the issue now, while it’s still a noise—not a breakdown.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?