A steady drip from your espresso machine can be more than just a nuisance—it's a sign that something’s wrong. Water leaks not only create messes on your countertop but can also lead to mold, electrical hazards, or permanent damage if ignored. The good news? Most leaks stem from predictable issues that are relatively simple to diagnose and repair with basic tools and care.

Whether you own a semi-automatic, super-automatic, or manual lever machine, understanding the anatomy of your device helps pinpoint where and why leaks occur. From worn seals to overfilled reservoirs, this guide breaks down the most frequent culprits behind espresso machine leaks—and how to fix them before they escalate.

Understanding How Espresso Machines Work

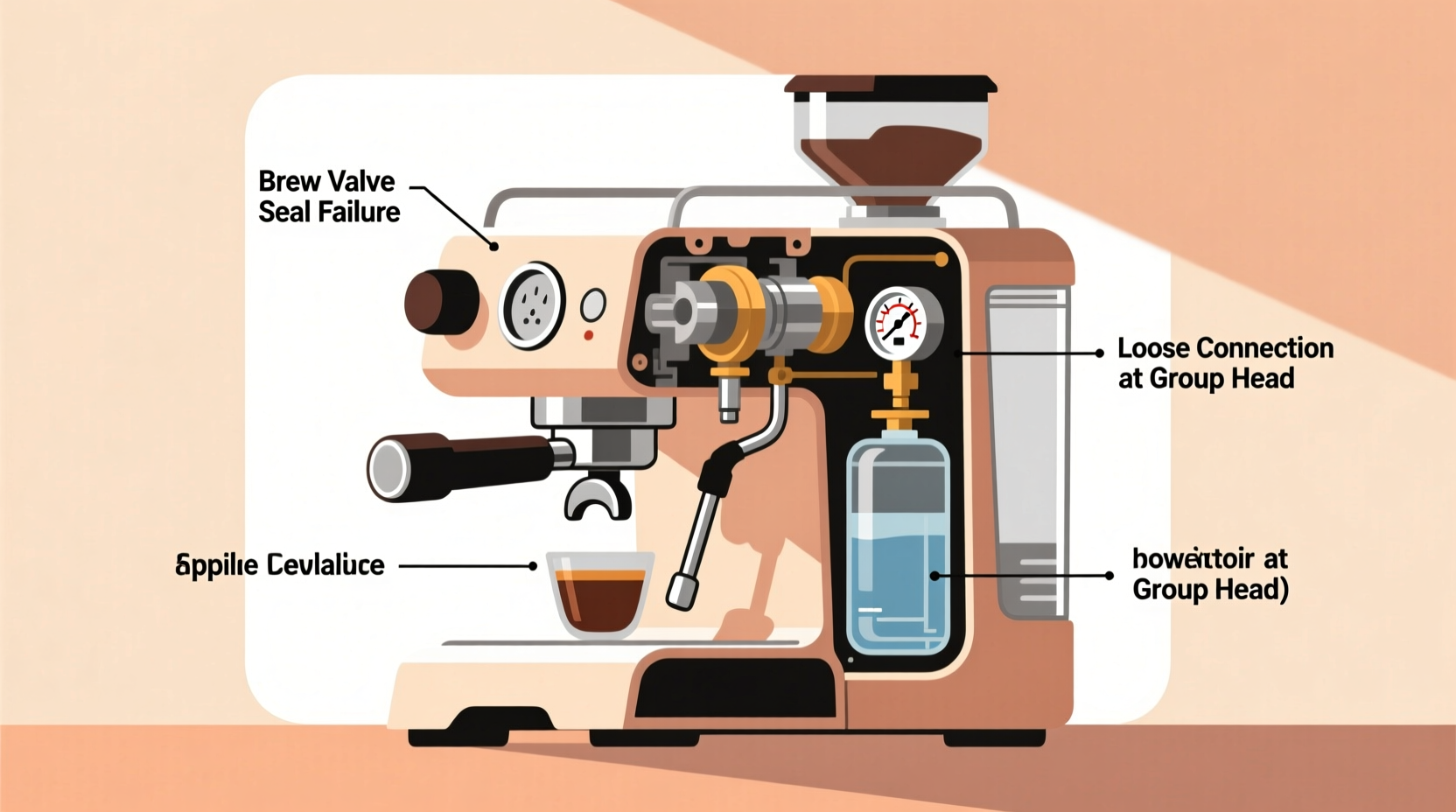

To troubleshoot leaks effectively, it helps to know how an espresso machine moves water through its system. Most home machines operate using a pump (either vibratory or rotary) that draws water from the reservoir or direct plumbing line. This water passes through a heating element—often a thermoblock or boiler—where it reaches optimal brewing temperature (around 90–96°C). From there, pressurized hot water flows through the group head and into the coffee puck.

After brewing, excess water drains via a drip tray or internal tubing. Steam wands use a separate path connected directly to the boiler for milk frothing. Any break in this sealed network—due to wear, misalignment, or poor maintenance—can result in leaks.

Because these systems rely on precise pressure and heat management, even minor cracks or degraded gaskets can compromise integrity and cause dripping.

Common Causes of Leaks and Their Fixes

1. Loose or Damaged Group Head Gasket

The group head gasket sits between the portafilter and the machine’s group head. Over time, constant exposure to high temperatures causes this rubber seal to harden, crack, or shrink. When compromised, it allows water to escape during brewing instead of flowing cleanly through the coffee grounds.

Symptoms: Water seeping around the edges of the portafilter during extraction, especially under pressure.

Fix: Turn off and cool the machine. Remove the portafilter and unscrew the retaining ring holding the gasket in place. Slide out the old gasket and insert a new one compatible with your model. Reassemble and test with a blank shot (no coffee).

2. Cracked or Warped Portafilter Basket or Seal

If the portafilter doesn’t seat properly due to warping or mineral buildup, pressure escapes during brewing. In some cases, the basket itself may develop micro-cracks from thermal shock or physical impact.

Symptoms: Uneven flow, spraying from the sides, or persistent dripping after pulling a shot.

Fix: Inspect the portafilter for visible cracks or deformation. Soak it in a descaling solution to remove limescale. If warping persists, replace the portafilter. Ensure proper alignment when inserting it into the group head—never force it.

3. Faulty Steam Wand O-Rings or Valve

Steam wand connections contain small o-rings that degrade over time. These seals prevent steam and condensation from leaking when the wand is closed. A failing o-ring often results in slow drips or sudden bursts of water when opening the knob.

Symptoms: Dripping from the tip of the steam wand, especially after steaming milk or during idle periods.

Fix: Shut off the machine and allow it to cool. Unscrew the tip of the steam wand and inspect the internal o-rings. Replace any that appear flattened, cracked, or brittle. Apply food-safe silicone lubricant before reassembly to extend seal life.

4. Overflowing Drip Tray or Clogged Drain Tube

Some leaks aren’t mechanical failures but rather oversights in maintenance. An overflowing drip tray gives the illusion of a machine leak, while a clogged drain tube prevents proper drainage of used water.

Symptoms: Puddles forming beneath the drip tray, water backing up into the machine base.

Fix: Empty the drip tray regularly. Check the drain hose (if applicable) for kinks or blockages. Flush the tube with warm water and a pipe cleaner. For plumbed-in models, ensure the waste line isn’t obstructed.

5. Cracked Boiler or Internal Pipe (Advanced Issue)

In older or heavily used machines, metal fatigue or limescale buildup can cause tiny fractures in the boiler or connecting pipes. These leaks typically occur internally and manifest as moisture near the base or strange noises during heating.

Symptoms: Persistent dampness inside the machine, hissing sounds, inconsistent pressure, or failure to heat.

Fix: Internal boiler issues require professional service. Do not attempt repairs unless qualified. Continuing to operate a machine with a cracked boiler poses safety risks, including potential scalding or electrical shorts.

Step-by-Step Leak Diagnosis Guide

Follow this logical sequence to identify and resolve the source of your leak efficiently:

- Power down and unplug the machine. Safety first—never work on a powered espresso machine.

- Dry all surfaces thoroughly. Use a lint-free cloth to wipe down the exterior, drip tray, group head, and steam wand.

- Fill the water reservoir and power on. Let the machine heat up normally without attaching the portafilter.

- Observe for early leaks. Watch the group head, steam wand, and base for signs of dripping during warm-up. Leaks at this stage suggest faulty seals or internal cracks.

- Attach the portafilter and run a blank shot. Place a cup under the group head and engage the brew cycle. Look for spray patterns or side leakage indicating gasket failure.

- Test the steam wand. Open the valve briefly and check for drips or sputtering. Close it and monitor for residual leakage.

- Inspect the drip tray and drain path. Confirm it’s not full and that water flows freely away from the machine.

- Repeat after replacing suspected parts. Verify the fix by running multiple cycles.

Preventative Maintenance Checklist

- Descale monthly (or every 2–3 months depending on water hardness)

- Clean group head and portafilter after each use

- Backflush with water weekly; use cleaning tablets monthly (for machines with three-way valves)

- Replace group head gasket every 6–12 months

- Inspect steam wand o-rings every 3 months

- Empty and rinse drip tray daily

- Check water reservoir for cracks or algae buildup

- Use filtered water to reduce mineral deposits

Do’s and Don’ts: Avoiding Common Mistakes

| Do’s | Don’ts |

|---|---|

| Use soft, damp cloths to clean the group head | Never submerge electrical components in water |

| Replace worn seals promptly | Ignore small drips—they often worsen over time |

| Run blank shots after changing gaskets | Over-tighten portafilters or knobs |

| Store the machine with an empty reservoir if unused for days | Leave standing water in the tank for weeks |

| Consult the user manual before disassembling parts | Use vinegar as a long-term descaling agent (can corrode metals) |

Real Example: Fixing a Persistent Leak on a Breville BES870

Mark, a home barista in Portland, noticed his Breville Barista Express was leaving puddles after every morning shot. At first, he assumed it was overflow from tamping too hard. But after checking grind size and distribution, the leak persisted—especially around the portafilter rim.

He followed the step-by-step diagnosis above. During the blank shot test, he observed water spraying laterally from the group head. That pointed to a seal issue. He removed the portafilter and found the group head gasket cracked and slightly lifted at one edge.

After ordering a replacement gasket online ($12), he replaced it in under 20 minutes. A quick backflush and test shot confirmed the leak had stopped. Mark now schedules gasket changes annually and keeps spares on hand.

“Most espresso problems are preventable with consistent care. A leaking machine isn’t necessarily broken—it’s often just asking for attention.” — Luca Moretti, Commercial Espresso Technician with 15 years of experience

Frequently Asked Questions

Is a small drip after brewing normal?

Yes, minimal dripping immediately after a shot ends is normal. The three-way brew valve releases residual pressure and flushes leftover coffee slurry into the drip tray. However, continuous dripping beyond 10–15 seconds indicates a problem with the valve or gasket.

Can I use plumber’s tape on espresso machine fittings?

No. Teflon tape (plumber’s tape) can shed fibers and contaminate water pathways. For sealing threaded connections, use food-grade thread sealant or silicone paste rated for potable water systems. Better yet, rely on factory-installed o-rings and gaskets designed for high heat and pressure.

Why does my machine leak only when I use the steam wand?

This usually points to degraded o-rings inside the steam wand assembly or a faulty steam valve. Condensation builds up in the wand during shutdown; if the seal fails, it escapes as liquid. Disassemble and inspect the wand tip and internal seals. Replacement kits are inexpensive and widely available.

Conclusion: Act Now to Protect Your Machine

A leaking espresso machine doesn’t have to mean expensive repairs or replacement. In most cases, the cause is a simple, fixable component like a worn gasket or clogged drain. By staying proactive with maintenance and responding quickly to signs of leakage, you protect both your investment and your daily ritual.

Start today: clean the group head, inspect your seals, and empty that drip tray. Small actions prevent big problems down the line. Whether you're troubleshooting a drip or optimizing performance, taking ownership of your machine’s health leads to better coffee and longer lifespan.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?