A garbage disposal that suddenly starts making loud, grinding, or clunking noises can be alarming. While some level of sound is normal during operation, excessive noise often signals an underlying issue. Ignoring these sounds can lead to more serious damage, costly repairs, or even the need for full replacement. The good news is that many causes of loud noises are fixable with basic tools and a bit of know-how. Understanding what’s happening inside the unit—and knowing what to inspect—can save time, money, and prevent kitchen downtime.

Common Causes of Loud Noises in Garbage Disposals

Loud noises from a garbage disposal aren’t random—they usually point to specific mechanical or operational problems. Identifying the type of noise can help narrow down the cause:

- Grinding or rumbling: Often indicates a jammed impeller or foreign object obstructing the blades.

- Metallic clanging: Suggests loose components, broken parts, or metal objects accidentally dropped into the unit.

- High-pitched whining: May mean worn bearings or motor strain due to lack of lubrication.

- Humming without grinding: Typically means the motor is running but the blades aren’t turning—often due to a jam.

- Banging or knocking: Could result from loose mounting hardware or internal component failure.

Each of these symptoms corresponds to different potential issues, ranging from simple fixes to more complex mechanical failures.

Step-by-Step Guide to Diagnosing the Problem

Before disassembling anything, follow this systematic approach to safely identify the source of the noise:

- Turn off power at the breaker. Safety first—disconnect electrical supply completely.

- Inspect visually using a flashlight. Look inside the disposal chamber for visible obstructions like silverware, bones, or fruit pits.

- Listen carefully when powering on (briefly). Note the exact sound: grinding, humming, clanking?

- Test the reset button. Located on the bottom of most units; press if it’s popped out.

- Manually rotate the impellers. Use an Allen wrench inserted into the bottom center hole to turn the flywheel back and forth.

- Check for looseness in mounting. Shake the unit gently—excessive movement suggests loose mounting assembly.

- Run water and test again after clearing jams. If noise persists, further inspection is needed.

This process helps rule out common culprits like jams and tripped motors. If the unit still makes noise after these steps, deeper investigation is required.

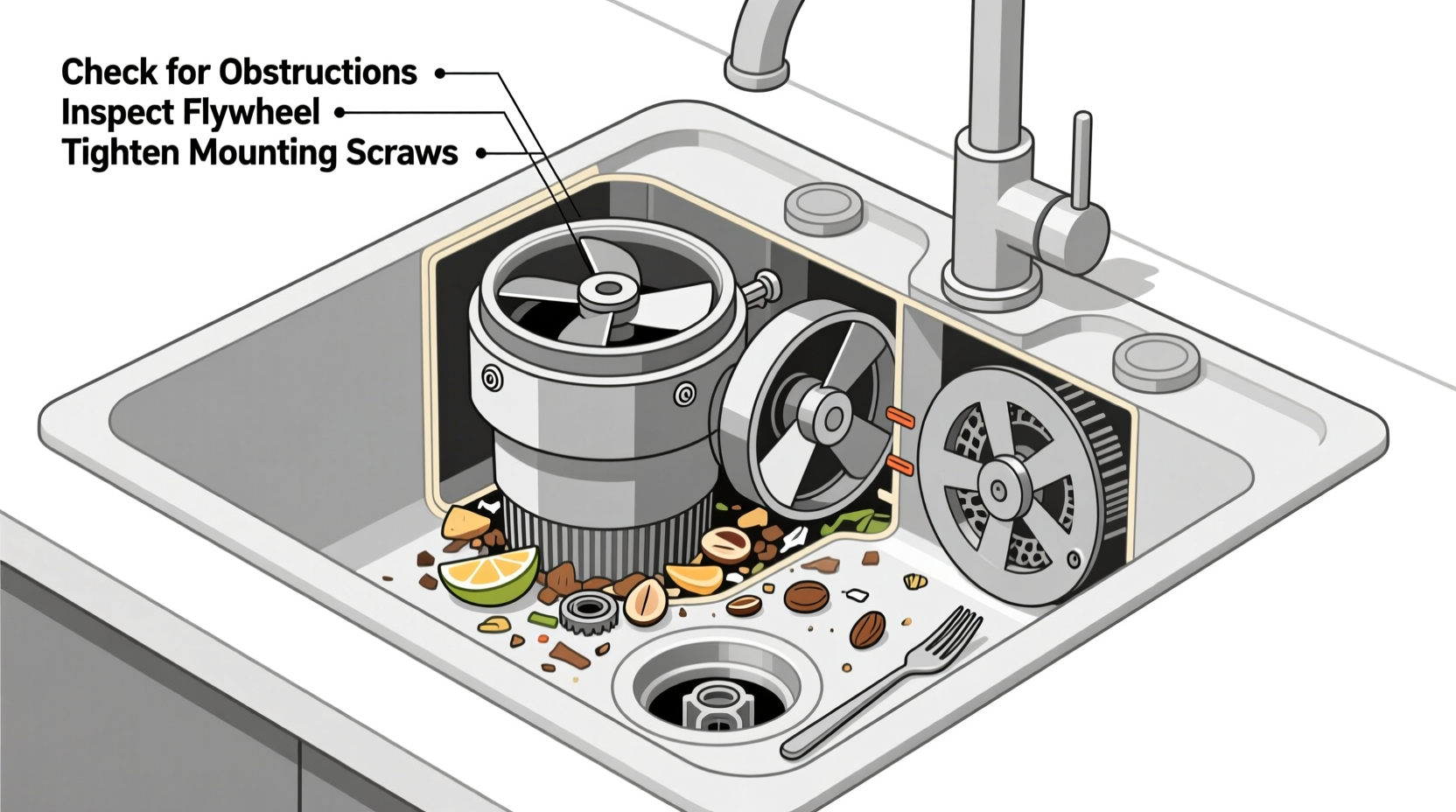

What to Check: A Detailed Inspection Checklist

Use this checklist to methodically evaluate each potential failure point in your garbage disposal:

- ✅ Power disconnected at circuit breaker

- ✅ Reset button pressed on unit base

- ✅ No visible debris inside grinding chamber

- ✅ Impellers rotate freely with Allen wrench

- ✅ Drain flange and splash guard secure and clean

- ✅ Mounting assembly tight (check screws and mounting ring)

- ✅ No rattling sounds indicating loose internal parts

- ✅ Unit doesn’t vibrate excessively when running

- ✅ No burning smell or smoke (sign of motor burnout)

- ✅ Test run with cold water flowing steadily

Completing this checklist ensures you don’t overlook simple fixes. Many homeowners find that a jammed impeller or loose mounting screw resolves the issue quickly.

When Foreign Objects Are the Culprit

One of the most frequent reasons for loud grinding or clunking is foreign objects lodged in the grinding chamber. Items like spoons, bottle caps, chicken bones, or even small toys can slip down the drain unnoticed. These objects prevent the impellers from rotating smoothly, causing strain on the motor and producing sharp, irregular noises.

To remove stuck items:

- Ensure power is off.

- Use needle-nose pliers or tongs to extract visible objects.

- If not accessible from above, access may require removing the disposal from the sink mount.

- Once removed, manually spin the flywheel to confirm smooth rotation.

Never use your fingers to retrieve objects—even with power off, accidental activation could occur.

“Over 60% of service calls for noisy disposals are due to foreign object jams or minor mechanical binding. Most can be resolved without professional help.” — Mark Reynolds, Licensed Appliance Technician with 18 years of experience

Internal Component Failures: Bearings, Impellers, and Motors

If no obstructions are found and the impellers rotate freely, yet loud noises persist, the issue may lie within internal components. Over time, wear and tear take a toll, especially in units used daily.

Worn Bearings

The motor shaft relies on bearings to spin smoothly. When these degrade, they produce a high-pitched squeal or constant grinding. This sound often increases with use and may be accompanied by heat buildup.

Cracked or Broken Impellers

Impellers (also called lugs or shredder rings) are responsible for pulverizing food waste. Made of stainless steel or galvanized metal, they can crack or break under stress—especially when hard items like pits or shells are disposed of regularly. Damaged impellers create imbalance and generate rhythmic banging.

Motor Burnout or Strain

A humming noise without blade movement typically points to a seized motor or capacitor failure. In older models, continuous overloading reduces motor efficiency and leads to overheating. Once a motor begins to fail, replacement is usually the only option.

| Component | Symptom | Repair Option | Replacement Needed? |

|---|---|---|---|

| Foreign Object | Intermittent clunking, jammed rotation | Remove object, reset unit | No |

| Loose Mounting | Vibration, knocking | Tighten mounting screws | No |

| Worn Bearings | High-pitched whine, heat | Lubrication ineffective | Yes (unit replacement) |

| Broken Impeller | Rhythmic banging, poor grinding | Not repairable | Yes |

| Seized Motor | Humming, no rotation | Reset or manual spin | Possible |

This comparison highlights which issues can be fixed and which typically require replacing the entire unit.

Mini Case Study: Resolving a Persistent Grinding Noise

Sarah, a homeowner in Portland, noticed her disposal began making a harsh grinding sound every time she turned it on. Initially, she assumed it was normal wear, but the noise worsened over two weeks. She followed basic troubleshooting: pressed the reset button, ran ice cubes through it, and checked for visible blockages—all with no improvement.

Determined to avoid a service call, Sarah consulted the manufacturer’s manual and located the hex socket on the bottom of the unit. Using a 1/4-inch Allen wrench, she attempted to rotate the flywheel but found it resisted movement. After applying gentle back-and-forth pressure, she felt it suddenly release. Upon restarting, the unit operated much more quietly—though a faint metallic tick remained.

She then disconnected the disposal from the sink and inspected the interior from below. With a flashlight, she spotted a small piece of a plastic utensil wedged between the impeller and the grind ring. Removing it eliminated the ticking sound entirely. Total time: 45 minutes. Cost: $0.

Sarah’s experience shows how methodical inspection and basic tools can resolve what seems like a major malfunction.

Preventative Measures to Reduce Future Noise Issues

Many noise problems stem from improper use or lack of maintenance. Implementing a few habits can extend the life of your disposal and keep it running quietly:

- Avoid disposing of fibrous foods like corn husks, celery stalks, or onion skins—they wrap around impellers and cause jams.

- Don’t put hard items down the drain such as bones, fruit pits, coffee grounds (in excess), or grease, which solidifies and creates clogs.

- Run cold water before, during, and after use to flush debris and cool the motor.

- Clean monthly with ice and salt to scour buildup from the grind chamber.

- Never use chemical drain cleaners—they corrode internal components and void warranties.

Frequently Asked Questions

Can I lubricate my garbage disposal to reduce noise?

While garbage disposals don’t have traditional lubrication points, running a small amount of vegetable oil (1–2 tablespoons) down the drain occasionally can help condition internal seals and reduce friction-related noise. However, avoid overuse, as oil can build up and attract debris.

Is it safe to use an electric disposal if it’s making noise?

Occasional minor noise may not be dangerous, but persistent grinding, screeching, or banging should not be ignored. Continuing to operate a damaged unit can overheat the motor, damage plumbing, or create safety hazards. Turn it off and investigate the cause promptly.

How long should a garbage disposal last before needing replacement?

Most disposals last between 8 and 15 years with regular use and proper care. Units subjected to heavy loads or misuse may fail sooner. Signs of aging include slow grinding, frequent jams, and chronic noise—even after maintenance.

Conclusion: Take Action Before It Gets Worse

A noisy garbage disposal isn’t just annoying—it’s a warning sign. Whether it’s a simple jam or a failing motor, addressing the issue early prevents bigger problems down the line. Most causes of loud noises are diagnosable and often fixable without professional help. By following a logical inspection process, understanding the mechanics involved, and practicing preventative care, you can maintain a quiet, efficient disposal for years.

Don’t wait until the unit fails completely. Take the time today to inspect your disposal, clear any obstructions, and ensure all components are secure. Your kitchen—and your ears—will thank you.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?