Kombucha brewing is a rewarding process that blends tradition, science, and flavor. But even experienced fermenters can hit roadblocks—especially when the fizz doesn’t come through. Flat kombucha is more than just disappointing; it’s a sign that something in the fermentation process has gone off track. Understanding the root causes of poor carbonation and other fermentation issues is essential for crafting consistently bubbly, tangy, and refreshing batches.

Carbonation in kombucha results from a secondary fermentation where yeast consumes sugar and produces carbon dioxide in a sealed environment. When this doesn’t happen effectively, the result is a still, lifeless drink. The reasons range from temperature imbalances to ingredient choices and container selection. This guide breaks down the most common problems, offers actionable solutions, and equips you with the knowledge to troubleshoot like a pro.

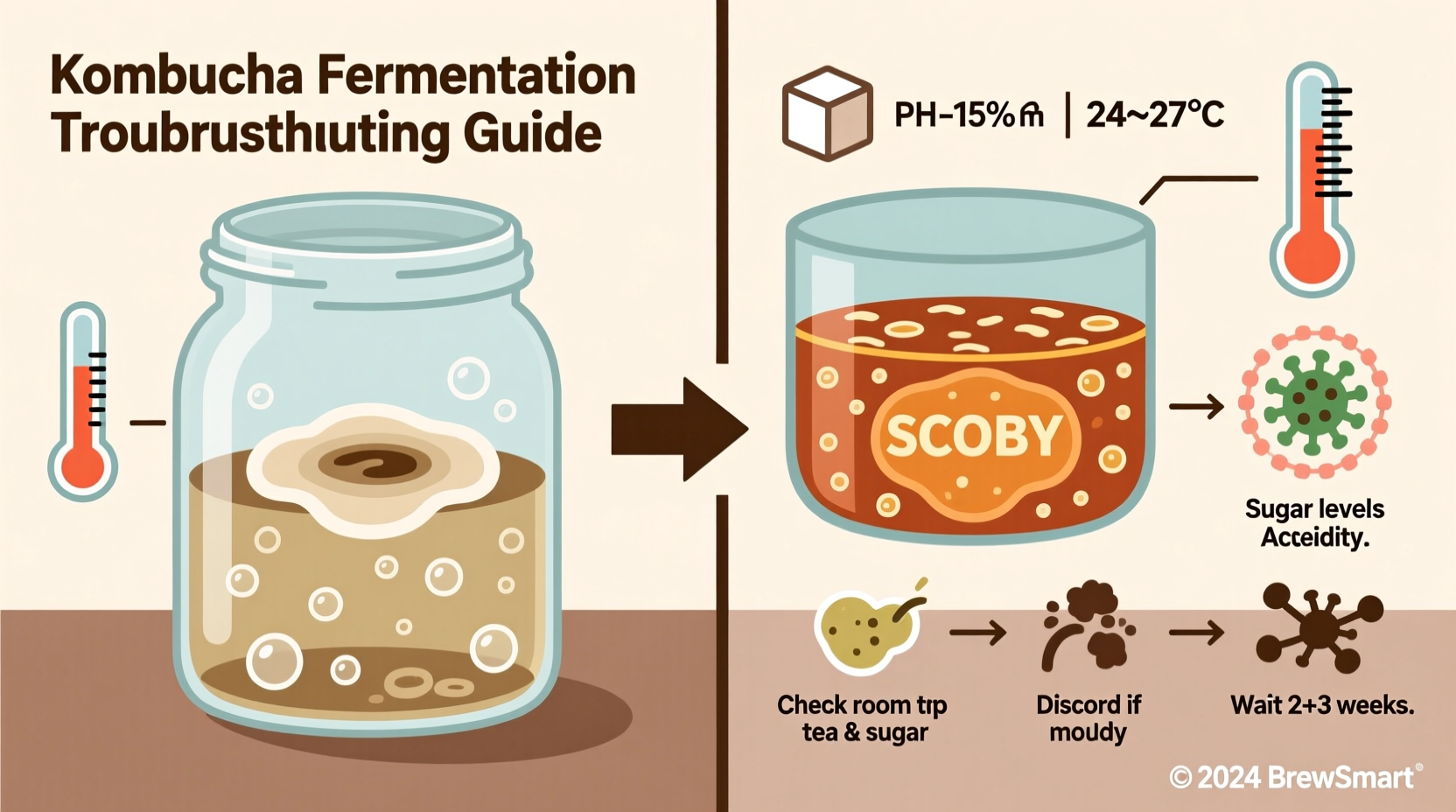

Understanding Kombucha Fermentation Basics

Kombucha is made through a two-stage fermentation process involving symbiotic cultures of bacteria and yeast (SCOBY), sweetened tea, and time. In the first fermentation, the SCOBY consumes sugar and caffeine, producing organic acids, trace alcohol, and minimal carbonation. This stage yields a tart, vinegary liquid—great for health but lacking in bubbles.

The real carbonation happens during the second fermentation (or “bottle phase”), where the kombucha is transferred into sealed bottles with added sugars or fruit. Here, residual yeasts continue fermenting, creating CO₂ that dissolves into the liquid under pressure. If any part of this process falters, carbonation suffers.

Key factors influencing successful carbonation include:

- Temperature: Ideal range is 72–78°F (22–26°C).

- Sugar availability: Enough fermentable sugar must remain or be added.

- Yeast activity: Healthy yeast populations are crucial for gas production.

- Bottle seal integrity: Pressure must be contained to dissolve CO₂ into the liquid.

- Fermentation time: Under- or over-fermenting both lead to flat or overly sour results.

Common Reasons Your Kombucha Isn’t Carbonating

When kombucha fails to carbonate, it’s rarely due to a single factor. More often, it's a combination of missteps in preparation, environment, or timing. Below are the most frequent culprits and their fixes.

1. Inadequate Sugar for Secondary Fermentation

The second ferment requires additional sugar—either from fruit, juice, or plain sugar—to feed the yeast. Without it, there’s nothing left to convert into CO₂.

Solution: Add 1–2 tablespoons of sugar, honey, or chopped fruit per liter before bottling. Fruit like ginger, berries, or citrus work well and add flavor.

2. Poor Bottle Seal or Wrong Container Type

If bottles don’t seal tightly, CO₂ escapes instead of building pressure. Plastic soda bottles may bulge if working correctly, while glass bottles require swing-top closures designed for carbonation.

Solution: Use only bottles rated for pressure, such as flip-top Grolsch-style bottles or PET plastic soda bottles. Avoid mason jars unless specifically designed for carbonation—they can explode under pressure.

3. Low Fermentation Temperature

Cool environments slow down yeast metabolism. Below 68°F (20°C), fermentation becomes sluggish or stalls entirely.

Solution: Move bottles to a warmer spot—near a radiator (not on it), on top of the fridge, or in a cupboard above room temperature. Consider using a fermentation heating pad if ambient temps are consistently low.

4. Over-Fermented First Ferment

If the initial ferment goes too long, most of the sugar is consumed, leaving little fuel for carbonation. Over-fermented kombucha tastes sharply vinegary and lacks sweetness.

Solution: Limit first fermentation to 7–14 days depending on temperature and taste. Taste test regularly after day 7. Stop when it’s pleasantly tart with a hint of sweetness.

5. Dead or Inactive Yeast

Pasteurized ingredients, chlorinated water, or exposure to mold-killing agents can kill yeast. Without active yeast, no CO₂ is produced.

Solution: Ensure all equipment is clean but not sterilized with harsh chemicals. Use raw cane sugar and filtered water. Reserve some liquid from a previous batch to inoculate the next one with live cultures.

“Many home brewers forget that carbonation depends on live yeast—not just the SCOBY. Killing the yeast kills the fizz.” — Dr. Lena Torres, Microbiologist & Fermentation Scientist

Troubleshooting Table: Diagnose Your Flat Kombucha

| Issue | Symptoms | Fix |

|---|---|---|

| Insufficient sugar in second ferment | No bubbles, flat taste | Add 1 tsp sugar or fruit per bottle before sealing |

| Cold fermentation environment | No pressure buildup after 3+ days | Move to warmer area (72–78°F) |

| Leaky or improper bottles | Lid loose, no hiss when opened | Use proper carbonation-rated bottles with tight seals |

| Over-fermented base | Very sour, no sweetness left | Shorten first ferment; taste at day 7 |

| Dead yeast culture | No activity even after 5 days | Inoculate with fresh starter tea; avoid chlorine |

| Too short second ferment | Mild tartness, no fizz | Wait 3–7 days longer; burp carefully to check pressure |

Step-by-Step Guide to Fixing and Preventing Carbonation Problems

Follow this proven sequence to revive a failed batch or ensure success in your next brew.

- Assess the current batch: Open a bottle gently. Is there any pressure? A slight hiss means partial carbonation. None suggests a deeper issue.

- Check the temperature: Measure the room where bottles are stored. If below 70°F, move them to a warmer location.

- Add fermentable sugar: For flat bottles, carefully open, add ½–1 teaspoon of sugar or juice per 16 oz, reseal, and return to warm storage.

- Wait and monitor: Allow 2–4 more days. Gently squeeze plastic bottles daily to check firmness (don’t shake).

- Reinforce with starter liquid: If no progress, mix in ¼ cup of unflavored, actively fermenting kombucha from a healthy batch to reintroduce live yeast.

- Prevent future failures: Standardize your process: consistent sugar ratios, reliable bottles, controlled temperatures, and timed ferments.

- Store properly post-carbonation: Once fizzy, refrigerate immediately to halt fermentation and preserve carbonation.

Mini Case Study: Reviving a Stalled Batch

Sarah, a home brewer in Portland, Oregon, noticed her last three kombucha batches were consistently flat. She followed recipes precisely but lived in a cooler climate (average 65°F indoors). Her bottles showed no pressure after seven days of second fermentation.

After reviewing her process, she identified two issues: she was using mason jars with standard lids (not airtight) and fermenting in a basement pantry at 64°F. She switched to swing-top bottles and moved the batch to a cupboard near her oven, raising the temp to 75°F. She also added 1 tablespoon of apple juice per liter before rebottling.

Within four days, the bottles were firm. Upon chilling and opening, the kombucha had a crisp, effervescent mouthfeel. Sarah now maintains a small thermometer in her brewing area and uses a dedicated shelf for fermentation.

Do’s and Don’ts of Kombucha Carbonation

| Do’s | Don’ts |

|---|---|

| Use fresh, raw ingredients and unchlorinated water | Use tap water with chlorine or chloramine |

| Add sugar or fruit to every second ferment | Bottle without adding extra fermentables |

| Ferment in a warm, stable environment (72–78°F) | Store bottles in cold basements or garages |

| Use bottles designed for carbonation | Seal mason jars with regular metal lids |

| Refrigerate once carbonated to stop fermentation | Leave bottles at room temperature indefinitely |

FAQ: Common Questions About Kombucha Fermentation

Why does my kombucha taste alcoholic?

A slight alcohol presence (usually under 0.5%) is normal in kombucha due to yeast activity. Extended fermentation or excessive sugar can increase alcohol levels. To reduce it, shorten the first ferment, lower sugar input, or refrigerate earlier.

Can I use honey instead of sugar for carbonation?

Yes, but only in the second ferment. Raw honey contains its own microbes and should be used sparingly. Avoid using honey in the first ferment if you’re relying on a traditional SCOBY, as it may inhibit growth (except in a \"jun\" culture, which thrives on honey).

How long should the second fermentation take?

Typically 3–7 days at 72–78°F. Warmer temperatures speed it up; cooler ones slow it down. Check daily by gently squeezing plastic bottles or doing a careful “burp test” with glass. Refrigerate once desired fizz is achieved.

Final Checklist for Bubbly Success

- ✅ Used non-chlorinated water and quality tea

- ✅ Added sugar or fruit in second ferment

- ✅ Bottled in airtight, pressure-safe containers

- ✅ Stored bottles in a warm (72–78°F), dark place

- ✅ Waited 3–7 days before refrigerating

- ✅ Burped bottles occasionally to prevent over-pressurization

- ✅ Refrigerated promptly once carbonated

Conclusion: Turn Flat Into Fizzy

Flat kombucha doesn’t mean failure—it’s feedback. Each batch teaches you more about your environment, ingredients, and process. With attention to temperature, sugar, vessel integrity, and timing, you can consistently produce sparkling, flavorful kombucha at home. Don’t let a still batch discourage you. Diagnose, adjust, and re-ferment with confidence. The perfect fizz is within reach.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?