There’s nothing more frustrating than planning a family dinner, only to find your oven still hasn’t reached the desired temperature after 30 minutes. While ovens typically take 10 to 15 minutes to preheat, delays beyond that signal an underlying issue. Understanding the causes of slow preheating—ranging from simple fixes to serious mechanical faults—is essential for maintaining cooking efficiency and safety. This guide explores common culprits, provides actionable solutions, and clarifies when professional intervention is necessary.

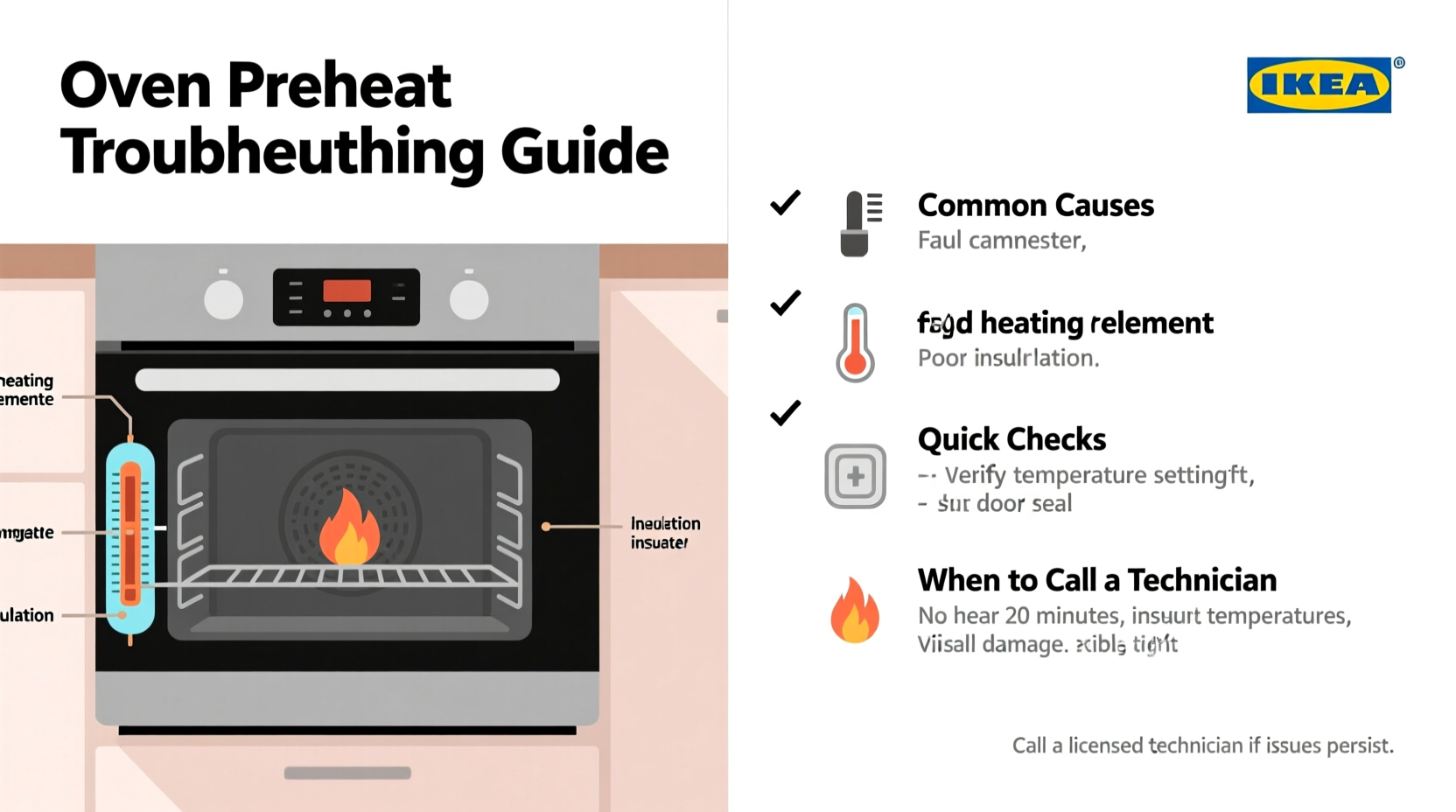

Common Reasons Your Oven Takes Too Long to Preheat

Oven preheating times depend on several factors, including model type, age, ambient kitchen temperature, and internal components. However, if your oven consistently exceeds 20–25 minutes to reach standard baking temperatures (350°F to 400°F), one or more issues may be at play.

- Faulty heating elements: Electric ovens rely on bake and broil elements. If either fails, heat output drops significantly.

- Defective thermostat or temperature sensor: An inaccurate reading prevents the oven from knowing when it has reached the set temperature.

- Door seal leaks: A damaged or loose gasket allows heat to escape, forcing the oven to work harder and longer.

- Old or inefficient model: Older ovens, especially those over 10 years old, often lack modern insulation and heating technology.

- Cold kitchen environment: Garages or unheated spaces can drastically increase preheat time.

- Convection fan failure: In convection ovens, a non-working fan disrupts even heat distribution, prolonging preheating.

Step-by-Step Guide to Diagnose Slow Preheating

Before calling a technician, conduct a systematic check to identify potential problems. Many issues can be resolved with minimal effort or inexpensive parts.

- Verify actual temperature: Use an independent oven thermometer placed in the center rack. Set the oven to 350°F and monitor how long it takes to reach that mark. If the built-in display shows “preheated” but the thermometer reads much lower, there’s a calibration or sensor issue.

- Inspect the heating elements: For electric ovens, visually examine the bottom (bake) and top (broil) elements. Look for signs of blistering, warping, or separation. A broken element won’t glow red uniformly when activated.

- Check the door seal: Close the door on a dollar bill at various points around the perimeter. If you can pull the bill out easily, the seal is compromised. Also look for cracks, brittleness, or visible gaps.

- Listen for the convection fan: In convection models, you should hear the fan running shortly after preheating begins. Silence may indicate motor failure.

- Review recent repairs or cleaning: Self-cleaning cycles can damage sensors or wiring. Ensure no residual cleaner residue is interfering with components.

- Test circuit breakers: For electric ovens, ensure the correct breaker is fully engaged. A partially tripped breaker reduces power delivery.

Do’s and Don’ts When Troubleshooting Oven Preheat Issues

| Do’s | Don’ts |

|---|---|

| Use an oven thermometer to verify accuracy | Ignore error codes on digital displays |

| Clean the oven regularly to prevent grease buildup near sensors | Attempt internal electrical repairs without disconnecting power |

| Replace worn door gaskets promptly | Use abrasive cleaners on heating elements |

| Keep vents around the oven unobstructed | Run the oven empty at high temps for extended periods unnecessarily |

| Reset the oven by turning off the breaker for 5 minutes | Continue using an oven that emits smoke or burning smells |

When to Call a Technician: Warning Signs You Can’t Ignore

Some problems require professional diagnosis and repair. Attempting DIY fixes on gas lines, control boards, or internal wiring can lead to fire hazards or permanent appliance damage.

Call a certified technician if you observe any of the following:

- No heat at all: Neither the bake nor broil element glows, and the oven remains cold.

- Burning smell or smoke: Indicates electrical shorts, melting wires, or oil residue igniting on heating elements.

- Flickering display or error codes: Codes like F1, E0, or “PF” suggest electronic control board failure.

- Gas oven won’t ignite: Clicking sounds without ignition point to faulty igniters or gas valve issues.

- Inconsistent temperatures: Swings of more than 50°F above or below the set point, confirmed by a thermometer.

- Recent power surge or lightning strike: These events can fry sensitive electronics even if the oven appears functional.

“Ovens are complex appliances combining electrical, thermal, and sometimes gas systems. If basic troubleshooting doesn’t resolve the issue within 15 minutes, it’s safer and more cost-effective to consult a professional.” — Carlos Mendez, Appliance Repair Specialist with 18 years of field experience

Mini Case Study: The Persistent Preheat Delay

Sarah from Portland noticed her electric range took nearly 40 minutes to preheat for roasting vegetables. She initially assumed it was normal for her 12-year-old model. After placing an oven thermometer inside, she discovered the oven only reached 320°F despite the display showing “Preheated” at 400°F.

She checked the door seal—tight—and the heating elements appeared intact. However, upon closer inspection, she found the broil element was cracked near the terminal end. Though the bake element worked, the oven relied on both for rapid heating in some modes. Replacing the broil element restored normal preheat time to under 15 minutes. The total repair cost was $85 for the part and installation.

This case highlights how partial component failure can degrade performance without completely disabling the appliance. Regular observation and simple tools like a thermometer can catch issues early.

Preventive Maintenance Checklist

Regular care extends your oven’s lifespan and ensures consistent performance. Use this checklist monthly or quarterly:

- ✅ Clean spills and food debris from oven floor and walls

- ✅ Inspect door gasket for cracks or looseness

- ✅ Verify heating elements glow evenly (electric models)

- ✅ Test convection fan operation (if applicable)

- ✅ Wipe down control panel and buttons

- ✅ Check for error messages during startup

- ✅ Confirm oven reaches 350°F within 15 minutes using a thermometer

- ✅ Vacuum ventilation slots around the oven frame

Understanding Oven Types and Their Preheat Norms

Not all ovens heat at the same rate. Knowing your model’s expected behavior helps determine what’s abnormal.

| Oven Type | Avg. Preheat Time (350°F) | Common Issues |

|---|---|---|

| Standard Electric | 12–18 minutes | Failing bake element, sensor drift |

| Convection Electric | 9–14 minutes | Fan motor failure, blocked airflow |

| Gas Oven | 10–16 minutes | Igniter wear, gas flow restriction |

| Induction-Compatible (with oven) | 10–15 minutes | Electronic control glitches |

| Ovens Over 10 Years Old | 18–30+ minutes | Insulation degradation, outdated tech |

If your oven falls significantly outside these ranges, investigate further. Keep in mind that newer models with faster preheat features (e.g., “rapid preheat” or “turbo bake”) may achieve target temps in under 10 minutes.

FAQ: Common Questions About Oven Preheating

Why does my oven say “preheated” but feel cold inside?

This usually indicates a faulty temperature sensor or miscommunication between the sensor and control board. The oven thinks it’s hot enough based on incorrect feedback. Use an external thermometer to confirm. Sensor replacement typically costs $50–$150 and resolves the issue in most cases.

Can a dirty oven affect preheating speed?

Yes. Excessive grease and food residue absorb heat and insulate surfaces, slowing temperature rise. Carbonized spills can also emit odors or smoke when heated. Clean spills promptly and avoid harsh chemical removers near sensors or vents.

Is it worth repairing an old oven with preheat issues?

It depends. If your oven is over 12–15 years old and requires multiple part replacements (e.g., sensor, element, control board), investing in a new energy-efficient model may save money long-term. Modern ovens use up to 30% less energy and offer better heat consistency.

Conclusion: Take Action Before Small Issues Become Big Problems

An oven that takes forever to preheat isn’t just inconvenient—it’s a sign that something needs attention. Whether it’s a simple fix like replacing a worn gasket or a deeper issue like a failing control board, timely action preserves both appliance longevity and kitchen safety. Start with basic diagnostics: verify temperature accuracy, inspect components, and maintain cleanliness. When in doubt, don’t hesitate to call a qualified technician. Ignoring persistent problems risks higher repair bills or even fire hazards down the line.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?