If you've ever stood in your kitchen watching the oven temperature crawl toward 350°F while your recipe waits impatiently on the counter, you're not alone. A slow-to-preheat oven disrupts meal planning, extends cooking times, and can compromise the quality of your dishes. Baked goods may rise unevenly, meats might not sear properly, and delicate pastries could collapse before they even get started.

Ovens are designed to reach standard baking temperatures—typically between 325°F and 450°F—in 10 to 15 minutes under normal conditions. When that timeline stretches to 30 minutes or more, something’s wrong. The good news: most causes of delayed preheating are diagnosable and often fixable without replacing the entire appliance.

This guide breaks down the top reasons your oven might be lagging, how to identify each issue, and what you can do—whether it's a simple DIY adjustment or when it's time to call a technician.

How Long Should an Oven Take to Preheat?

Understanding what \"normal\" looks like is key to identifying a problem. Most modern electric and gas ovens should reach 350°F within 10–15 minutes. Convection ovens, which use a fan to circulate hot air, typically preheat even faster—often in under 10 minutes.

Several factors can influence preheat time slightly:

- Ambient kitchen temperature (colder rooms may slow initial heat-up)

- Oven age and insulation condition

- Whether the oven was previously used (residual heat helps)

- The accuracy of the thermostat display

But if your oven consistently takes over 20 minutes to reach target temperature, especially from a cold start, it's worth investigating further.

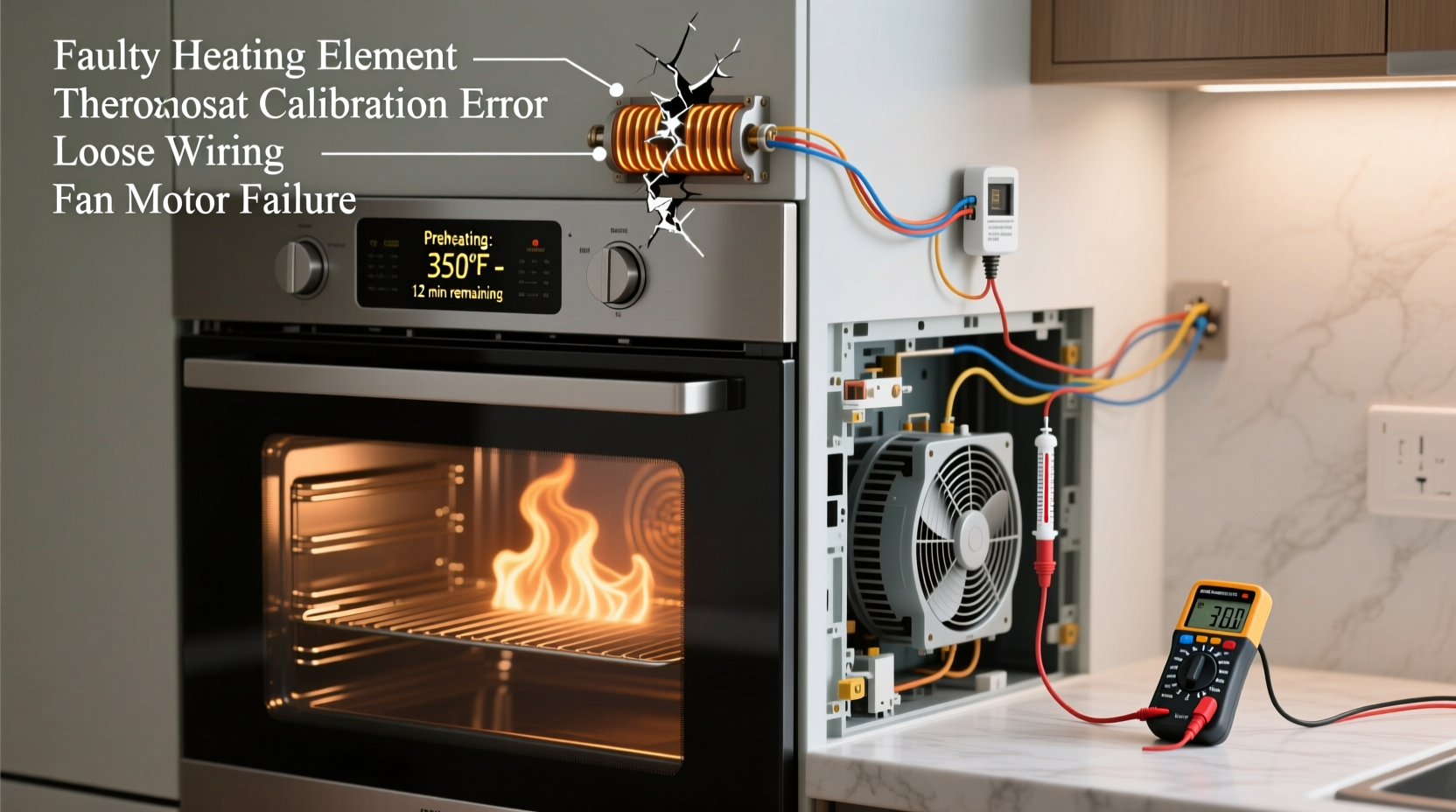

Common Causes of Slow Oven Preheating

Slow preheating rarely stems from a single mysterious flaw. Instead, it's usually one of several mechanical or maintenance-related issues affecting the oven’s ability to generate or retain heat efficiently.

1. Faulty or Weak Heating Elements (Electric Ovens)

In electric ovens, the main heating element is located at the bottom (and sometimes also at the top for broiling). If this coil is damaged, burned out, or degraded, it won’t produce sufficient heat. Even if it glows red, a partially failed element may only operate at reduced power.

Symptoms include:

- Visible gaps, blistering, or sagging in the heating coil

- Only part of the element glowing red

- Baking results that are uneven or take much longer than expected

Replacing a faulty heating element is a straightforward repair for most models and can restore full heating performance.

2. Igniter Problems (Gas Ovens)

Gas ovens rely on an igniter to open the gas valve and ignite the flame. Over time, igniters weaken and fail to heat up enough to trigger gas flow—even if they glow dimly. This results in no flame, or intermittent ignition, delaying or preventing proper heating.

A failing igniter often shows these signs:

- Faint orange glow but no \"whoosh\" of gas ignition

- Oven clicking repeatedly without lighting

- Long delays before the burner finally fires

Igniters are wear items and typically last 5–7 years. Replacing them costs under $50 for the part and can be done by a homeowner with basic tools.

“Over 60% of slow preheat complaints in gas ovens trace back to a weak or failing igniter. It’s the most overlooked component because people assume ‘if it glows, it works.’ But insufficient resistance means no gas release.” — Mark Reynolds, Appliance Repair Technician with 18 years of field experience

3. Poor Oven Door Seal

The oven door gasket (the rubber-like seal around the door) is critical for heat retention. If it’s cracked, brittle, warped, or covered in grease and debris, hot air escapes continuously during preheating. This forces the heating system to work harder and longer just to maintain temperature.

To test the seal:

- Close the door on a dollar bill placed at various points around the frame.

- Pull gently. If the bill slides out easily, the seal is compromised.

- Check for visible gaps, charring, or separation from the door.

Replacing the gasket is a low-cost fix and dramatically improves efficiency. Never ignore a damaged seal—it also increases energy bills and fire risk.

4. Thermostat or Temperature Sensor Issues

If the oven thinks it’s hotter than it actually is, it will stop heating prematurely. This happens when the temperature sensor fails or drifts out of calibration. Similarly, a malfunctioning thermostat can misread internal conditions, leading to inconsistent or incomplete heating cycles.

You can test this with an external oven thermometer. Place it inside and compare its reading to the oven’s display once the \"preheat complete\" signal sounds. A difference of more than 25°F indicates a calibration or sensor issue.

Some ovens allow manual recalibration through the control panel settings. Others require sensor replacement—a task that usually involves removing a screw or two and swapping wires.

5. Dirty Interior or Burned-On Residue

Excessive grease, food spills, and carbonized buildup absorb heat instead of reflecting it. A grimy oven must first burn off residue before effectively warming the cavity, adding minutes to preheat time. In extreme cases, smoke may appear during preheating as old grease burns away.

Regular cleaning prevents this. For stubborn grime, use a commercial oven cleaner or a paste of baking soda and water. Avoid steam-clean functions on heavily soiled ovens—they can bake on residue further if not followed by wiping.

Step-by-Step Diagnostic Checklist

Follow this sequence to pinpoint the cause of your oven’s sluggish preheating. Many issues can be ruled in or out without tools.

- Verify the actual temperature: Place an oven-safe thermometer inside and monitor real-time heat rise. Does it match the display?

- Inspect the heating element (electric): Look for damage, discoloration, or uneven glowing. Listen for buzzing or flickering during operation.

- Observe the igniter (gas): Watch during startup. Does it glow brightly and lead to immediate gas ignition? Or does it stay on for more than 90 seconds without lighting?

- Test the door seal: Perform the dollar bill test. Also check for visible wear or warping.

- Assess interior cleanliness: Shine a flashlight on walls and floor. Are there thick layers of grease or baked-on food?

- Listen for unusual sounds: Clicking, popping, or prolonged humming may indicate electrical or gas flow problems.

- Check for error codes: Modern ovens often display fault codes (e.g., F1, E2) that point to specific components.

If all visual and functional checks pass but preheating remains slow, the issue may lie in less accessible components like the control board or safety valve—best handled by a professional.

Do’s and Don’ts of Oven Maintenance

| Do | Don't |

|---|---|

| Clean spills promptly after cooling | Use abrasive scrubbers on glass or enamel |

| Inspect the door seal every 3 months | Ignore persistent smoke during preheat |

| Replace worn heating elements early | Attempt gas line repairs without certification |

| Use an external thermometer monthly | Block oven vents with foil or pans |

| Ventilate the kitchen during self-cleaning cycles | Run self-clean mode with pets nearby (toxic fumes) |

Real-World Example: Sarah’s Gas Oven Struggle

Sarah, a home baker in Portland, noticed her favorite sourdough loaf wasn’t rising properly. She timed her oven preheat and was shocked to find it took 38 minutes to reach 425°F—nearly triple the expected time. She checked the igniter and saw it glowing faintly but never triggering the gas flame. After 90 seconds, it would shut off, then restart.

She called a technician who diagnosed a failing igniter with insufficient resistance. The part cost $42, and installation took 20 minutes. Post-repair, her oven reached 425°F in 11 minutes. Her bread rose evenly again, and she regained confidence in her weekly baking routine.

Sarah’s case highlights how a small, inexpensive component can have an outsized impact on performance—and why visual cues matter more than assumed functionality.

When to Call a Professional

While many oven issues are DIY-friendly, some require expert handling:

- Gas valve malfunctions: Any suspicion of gas leaks (rotten egg smell) demands immediate professional attention.

- Control board failures: These involve complex circuitry and software diagnostics.

- Wiring issues: Burnt, frayed, or loose wires inside the oven should not be handled without electrical training.

- No heat at all: If neither the bake nor broil elements activate, the problem may be deeper than a single component.

Always unplug electric ovens or shut off the gas supply before attempting any inspection or repair. Safety should never be compromised for convenience.

Frequently Asked Questions

Why does my oven say “preheat complete” but feel cold inside?

This usually means the temperature sensor is faulty or the thermostat is miscalibrated. The oven thinks it’s hot based on incorrect feedback. Use an external thermometer to confirm. Recalibrate or replace the sensor as needed.

Can I speed up preheating by turning on both bake and broil elements?

Yes—many chefs use this trick. Turning on both elements simultaneously increases heat input and can cut preheat time by 30–50%. Just remember to turn off the broil element once the target temperature is reached to avoid burning the tops of dishes.

Does altitude affect oven preheating time?

Altitude doesn’t significantly change how fast an oven heats up, but it does affect cooking times and temperatures due to lower atmospheric pressure. However, the preheat phase itself remains largely unaffected.

Conclusion: Restore Speed and Confidence to Your Kitchen

A slow preheating oven isn’t just an inconvenience—it undermines recipe accuracy, wastes energy, and erodes trust in your appliances. But in most cases, the root cause is identifiable and fixable. From replacing a $40 igniter to cleaning decades of grime, restoring peak performance often requires minimal investment.

Start with the basics: verify the temperature, inspect the seal, and clean the interior. Then move to component checks. You might solve the issue yourself—or gather enough evidence to help a technician diagnose it quickly.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?