Printer jams are among the most frustrating disruptions in both home and office environments. They interrupt workflow, damage print jobs, and often lead to torn paper that’s difficult to remove without causing further issues. While occasional jams can happen, constant jamming signals an underlying problem—mechanical, environmental, or user-related. More importantly, repeated tearing of paper inside the machine can leave debris that worsens performance over time. Understanding the root causes and implementing preventive strategies not only saves time but also extends the life of your printer.

Common Causes of Frequent Printer Jams

Before addressing prevention, it's essential to identify what’s triggering the jams. Most recurring issues stem from a combination of mechanical wear, improper supplies, or environmental factors.

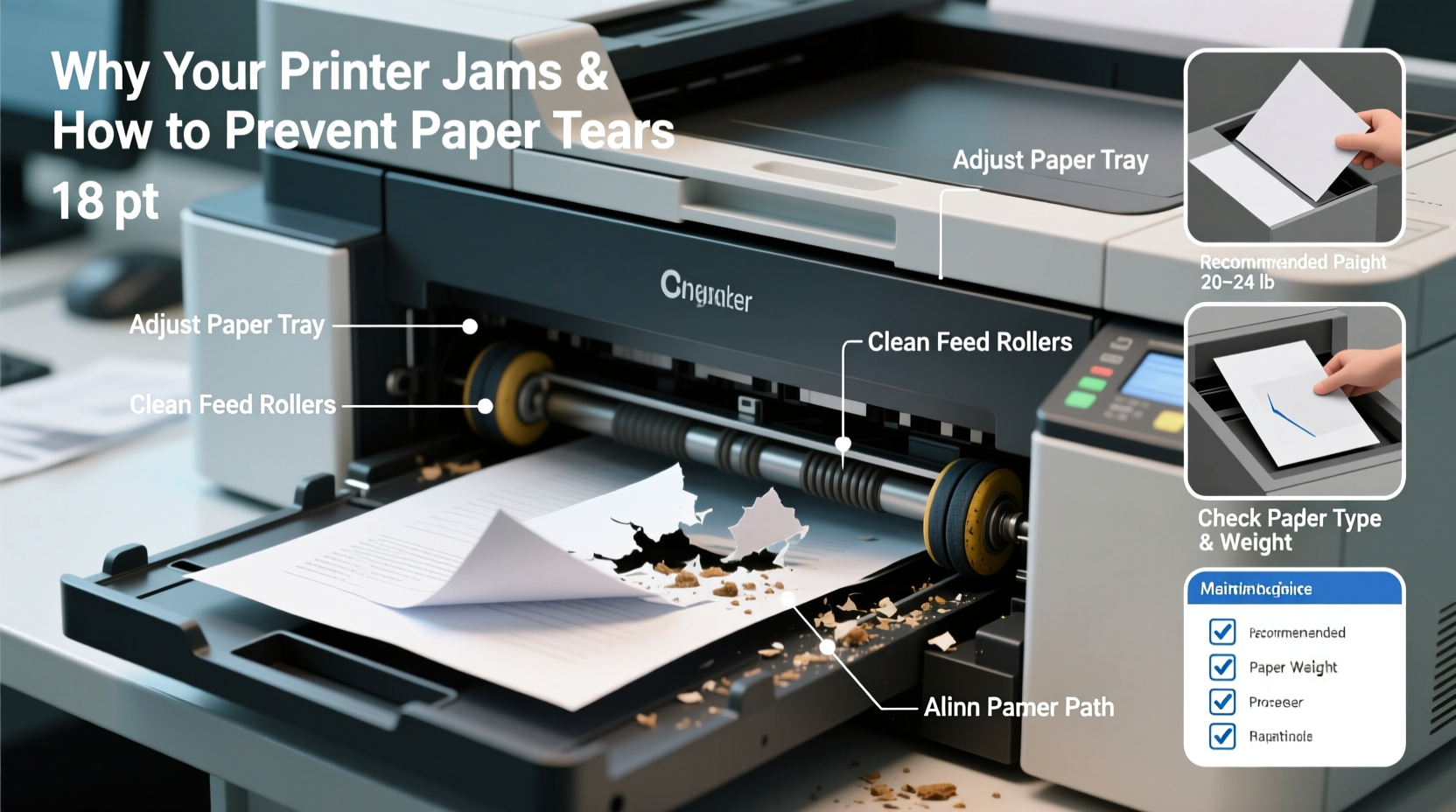

- Worn or dirty rollers: The feed and separation rollers pull paper through the printer. Over time, they accumulate dust, toner residue, or moisture, reducing grip and causing misfeeds.

- Incompatible or low-quality paper: Using paper that’s too thick, too thin, wrinkled, or non-standard size can confuse the printer’s feeding mechanism.

- Overloaded paper tray: Overfilling the input tray increases friction between sheets, making multiple sheets feed at once—a common cause of jams.

- Moisture-damaged paper: Humidity causes paper fibers to swell, increasing the likelihood of sticking or tearing during transport.

- Misaligned internal components: If the printer has been moved frequently or suffered impact, guides or rollers may be out of alignment.

- Firmware or software glitches: Outdated drivers or firmware can send incorrect signals to the paper handling system.

Step-by-Step Guide to Clearing a Jam Safely

When a jam occurs, especially one involving a torn sheet, how you respond matters. Incorrect removal can damage rollers or leave fragments behind. Follow this sequence carefully:

- Turn off the printer and unplug it. This prevents unexpected movement during clearance and protects internal circuits.

- Open all accessible panels—input tray, output tray, rear access door, and any side covers recommended by the manufacturer.

- Locate the jammed paper. Look for crumpled sheets or visible fragments. Use a flashlight if needed.

- Pull the paper slowly in the direction of paper travel. Never yank backward; this can tear the paper or damage gears.

- If the paper tears, check deeper pathways. Use tweezers (non-metallic if possible) to extract small pieces, avoiding contact with sensitive components.

- Clean rollers gently. Dampen a lint-free cloth with distilled water and wipe rollers in the direction of rotation. Let them dry completely before reassembly.

- Reassemble and test. Plug the printer back in, power it on, and run a test page using plain paper.

Some printers display jam locations via on-screen prompts. Consult your manual to interpret error codes like “Paper Jam Tray 1” or “Fuser Jam,” which guide you to the affected area.

Preventing Future Paper Tears: Best Practices

Once the immediate issue is resolved, focus shifts to long-term prevention. Many users overlook simple habits that dramatically reduce jam frequency.

| Do’s | Don’ts |

|---|---|

| Use manufacturer-recommended paper types and weights. | Use folded, creased, or recycled paper with rough edges. |

| Store paper in sealed containers away from humidity. | Leave paper exposed in damp basements or near windows. |

| Load paper below the maximum fill line in the tray. | Overstuff trays to avoid frequent refills. |

| Run a cleaning cycle monthly on inkjet models. | Ignore maintenance alerts or error history. |

| Align paper guides snugly against the stack. | Leave guides loose, allowing sideways slippage. |

Environmental control plays a bigger role than many realize. Printers perform best in stable conditions—ideally between 68°F and 77°F (20–25°C) with 40–60% relative humidity. Basements, garages, and sunlit rooms often fall outside this range, accelerating paper degradation and mechanical stress.

“Over 60% of service calls for laser printers involve paper handling issues—most of which could have been avoided with proper media selection and storage.” — Carlos Mendez, Senior Field Technician at OfficeTech Solutions

Mini Case Study: Resolving Chronic Jams in a Small Law Office

A downtown law firm with ten employees reported weekly printer jams, often resulting in torn documents mid-billing statement. Their HP LaserJet M404dn had become a source of daily frustration. An on-site assessment revealed three key issues: the paper was stored under a sink cabinet prone to leaks, the tray was consistently overfilled with mixed-weight stock, and no roller cleaning had occurred in over a year.

The technician recommended switching to moisture-resistant packaging, standardizing on 20 lb. bond paper, reducing tray load to 75% capacity, and scheduling bi-monthly roller wipes. Additionally, they enabled automatic jam recovery in the printer settings. After three months, jam incidents dropped from 3–4 per week to zero. Staff reported improved print quality and reliability, particularly during high-volume filing periods.

This case underscores how seemingly minor oversights compound into chronic problems—and how systematic correction yields outsized results.

Essential Maintenance Checklist

To keep your printer running smoothly and minimize paper tears, follow this routine checklist every 30–60 days, depending on usage volume:

- ✅ Inspect and clean feed and exit rollers with a lint-free cloth and distilled water.

- ✅ Remove and reload paper, fanning each ream before insertion.

- ✅ Check for firmware updates via the printer’s embedded web server or manufacturer app.

- ✅ Examine paper path for residual debris or fiber buildup.

- ✅ Verify alignment of paper guides and tray latches.

- ✅ Run a nozzle check (inkjet) or calibration page (laser) to confirm mechanical integrity.

- ✅ Replace worn pickup rollers if slipping is evident (typically after 50,000 pages).

High-volume users—offices printing more than 500 pages per week—should consider professional servicing annually. Technicians can inspect gear trains, replace worn belts, and lubricate moving parts inaccessible to end users.

Frequently Asked Questions

Why does my printer jam only when printing double-sided?

Duplex printing requires paper to make a longer path through additional rollers. If the reversing mechanism is worn or dirty, or if the paper is slightly curled, the second pass increases jam risk. Use flat, rigid paper and ensure duplex unit rollers are clean.

Can using third-party paper really cause more jams?

Yes. While many generic brands are reliable, others cut corners on consistency—varying thickness, edge smoothness, or moisture resistance. Reputable brands undergo rigorous testing for compatibility. For critical jobs, stick with known performers like Hammermill, Xerox, or Canon-branded paper.

Is it safe to use compressed air to clean inside the printer?

Use caution. Low-pressure canned air can dislodge dust, but excessive force may push debris deeper or damage delicate sensors. Never use household compressors, which can introduce moisture. Always power down first and avoid direct spray on rollers.

Conclusion: Take Control of Your Printer’s Performance

Constant printer jams aren't inevitable—they're indicators. Whether it's degraded rollers, poor paper quality, or environmental neglect, each jam offers a clue to improve your setup. By adopting a proactive maintenance routine, storing supplies correctly, and responding to early warning signs, you can eliminate most paper feeding issues. Preventing paper tears isn’t just about convenience; it protects your printer’s internal components and ensures professional-quality output every time.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?