If your sourdough starter is bubbling vigorously but fails to rise—meaning it doesn’t double in volume or collapse predictably—you’re not alone. This is one of the most common frustrations among home bakers. Bubbles indicate microbial activity, but a lack of lift suggests something is off in the balance of yeast, bacteria, food supply, or environment. The good news: this issue is almost always fixable with targeted adjustments.

Understanding why bubbling doesn’t equal rising requires looking beyond surface-level signs. True strength in a starter comes from consistent doubling within 4–8 hours after feeding, forming an airy structure that can leaven bread. When that doesn’t happen, even with visible fermentation, the root causes are often related to feeding practices, flour quality, temperature, or maturity of the culture.

Why Bubbling Doesn’t Mean a Healthy Starter

Bubbling is caused by carbon dioxide production from wild yeast and lactic acid bacteria fermenting sugars in flour. However, bubbles alone don't confirm a robust, leavening-capable starter. A starter may bubble due to:

- Overactive acid-producing bacteria (lactobacilli) outcompeting yeast

- Weak yeast colonies unable to produce enough gas for lift

- Inadequate gluten network formation in the starter matrix

- Exhaustion of food supply before peak rise occurs

As baking expert Ken Forkish explains:

“Bubbles are encouraging, but volume increase is what matters. A starter should reliably double—and then fall—in a predictable window. That’s the sign of balanced fermentation.” — Ken Forkish, Artisan Bread Baker & Author

The absence of rise despite bubbling usually means your starter is either undernourished, imbalanced, too cold, or not mature enough. Let’s break down how to diagnose and correct each factor.

Key Fixes That Work: Step-by-Step Adjustments

Solving a non-rising starter isn’t about drastic changes—it’s about systematic refinement. Follow this timeline over 3–7 days to restore strength and consistency.

Day 1: Reset Your Feeding Ratio

Many starters fail to rise because they’re being fed incorrectly. An unbalanced ratio starves microbes or creates overly acidic conditions.

Switch to a 1:2:2 feeding ratio immediately:

- 1 part mature starter

- 2 parts water (by weight)

- 2 parts flour (by weight)

This dilutes acidity and provides ample food. Use filtered water and unbleached all-purpose or whole grain flour (rye or whole wheat boost microbial diversity).

Day 2–3: Increase Feeding Frequency

If your starter peaks and collapses within 4–6 hours, feed it twice daily at 12-hour intervals—even if no visible activity remains. Frequent feeding rebuilds yeast populations weakened by bacterial dominance.

Example schedule:

- 7:00 AM – Discard all but 25g starter, feed 25g water + 25g flour

- 7:00 PM – Repeat same process

Track volume changes hourly using a clear jar with measurement lines. Look for steady expansion, not just bubbles on the surface.

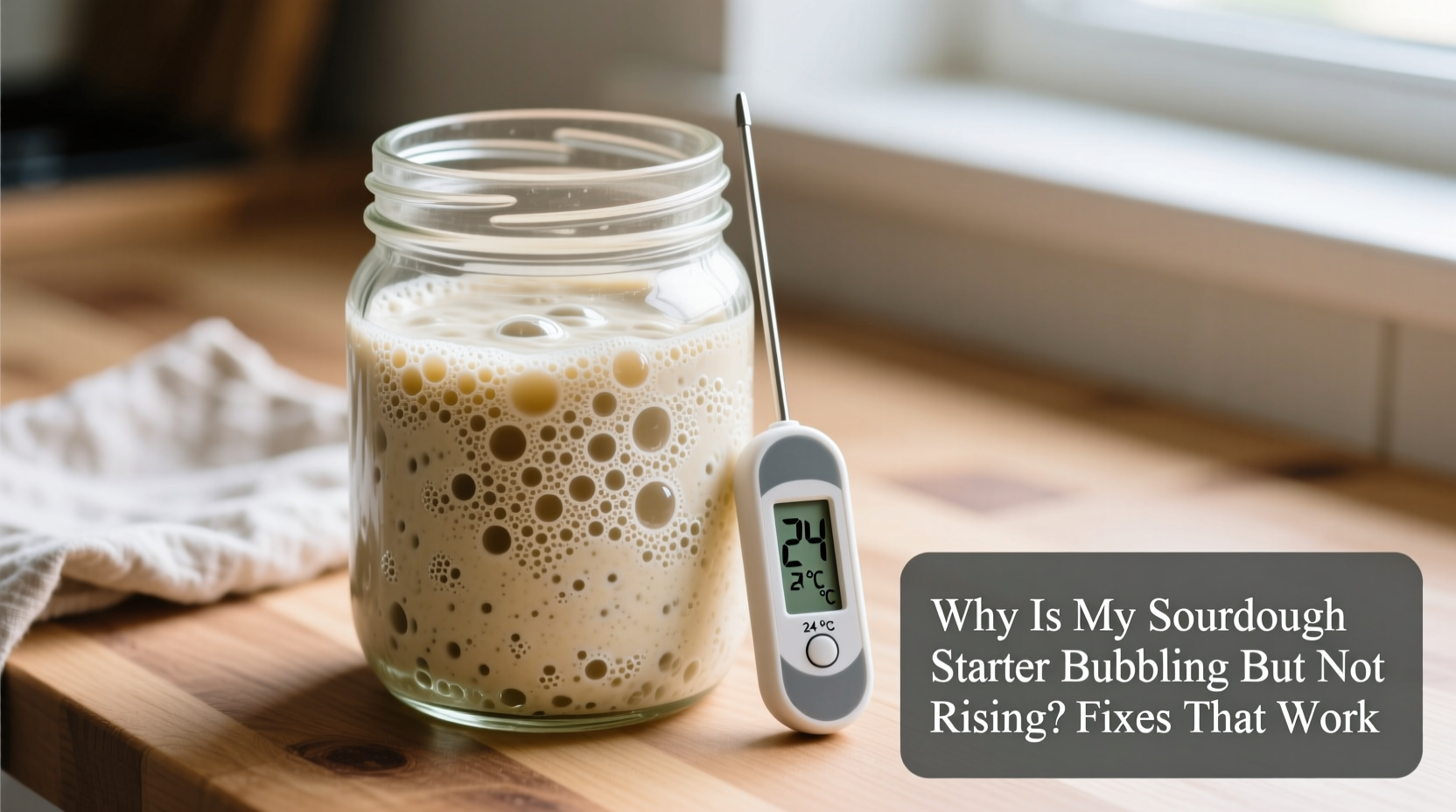

Day 4: Optimize Temperature

Yeast thrives between 70°F and 78°F (21°C–26°C). Below 68°F, activity slows dramatically; above 80°F, bacteria dominate and weaken structure.

If your kitchen is cool:

- Place starter near a warm appliance (oven with light on)

- Use a seedling mat or sous-vide setup to maintain 75°F

- Wrap jar in a towel to retain ambient heat

Avoid placing near drafts, AC units, or windows exposed to direct sunlight.

Day 5–7: Test for Maturity with a Float Test

Once your starter consistently doubles within 6–8 hours, perform a float test to check leavening power.

- Fill a glass with room-temperature water.

- Drop a teaspoon of starter into the water.

- If it floats, it’s ready for baking. If it sinks, continue refining.

Note: A sinker doesn’t mean failure—it means more feeding cycles are needed. Whole grain-heavy starters sometimes sink despite being active due to density, so rely primarily on visual rise.

Common Mistakes That Prevent Rise (And How to Avoid Them)

Even with regular feeding, subtle errors sabotage starter development. These pitfalls are often overlooked but easy to correct.

| Mistake | Why It Hinders Rise | Solution |

|---|---|---|

| Using chlorinated tap water | Chlorine kills beneficial microbes | Use filtered, bottled, or boiled-and-cooled water |

| Infrequent feeding (once daily) | Acidity builds up, weakening yeast | Feed twice daily until stable |

| Over-discarding or under-discard | Too little culture = slow recovery; too much = waste | Keep 20–25g leftover starter per feed |

| Only using white flour | Lacks nutrients for diverse microbiome | Add rye or whole wheat 1–2x/week |

| Covering too tightly | Traps pressure, distorts rise observation | Use loose lid, cloth + rubber band, or jar lid placed on top without screwing |

Flour Type Matters: Choosing the Right Food

Not all flours support strong starter development equally. While all-purpose flour works, certain types accelerate microbial balance and gas retention.

Rye flour, for example, contains high levels of soluble sugars and minerals that feed both yeast and lactobacilli rapidly. Many bakers report noticeable improvement in rise within 48 hours of introducing rye.

Try this weekly boost:

- Once per week, feed your starter with 50% rye flour and 50% all-purpose

- Observe increased bubble structure and faster rise time

- Return to regular flour afterward unless rye performs better long-term

Conversely, bleached flour or low-protein cake flour should be avoided—they lack the nutrients and gluten-forming proteins needed to trap gas effectively.

Real Example: Reviving a Stalled Starter

Sarah, a home baker in Portland, maintained her starter for three weeks. It bubbled actively every morning but never rose. She was discouraged and nearly discarded it.

She began logging observations: peak activity occurred at 5 hours, followed by rapid deflation. The smell was sharply vinegary—signaling excess acidity.

Her fixes:

- Switched to 1:2:2 feeding ratio with rye flour on day one

- Started feeding every 12 hours instead of once daily

- Moved the jar to a heating pad set to 75°F

- Used filtered water exclusively

By day four, her starter doubled in 6 hours and held its peak for nearly two hours before falling. On day six, she baked her first successful loaf with open crumb and proper oven spring.

“I thought I needed a new starter,” Sarah said. “But really, I just needed better conditions and consistency.”

Essential Checklist: Restore Your Starter in One Week

Follow this actionable checklist to troubleshoot and strengthen your starter:

- ✅ Switch to 1:2:2 feeding ratio (starter:water:flour by weight)

- ✅ Feed every 12 hours for 3–5 days, regardless of appearance

- ✅ Use unbleached all-purpose, whole wheat, or rye flour

- ✅ Use filtered or dechlorinated water

- ✅ Maintain temperature between 70°F–78°F (21°C–26°C)

- ✅ Store in a clear container with measurement markings

- ✅ Loosely cover to allow gas exchange

- ✅ Track rise height with a rubber band or marker

- ✅ Perform a float test after 5 days of consistent doubling

- ✅ Bake a small test loaf if float test passes

Stick with the full week even if early improvements appear. Consistency builds resilience.

Frequently Asked Questions

Can a starter be too bubbly?

Yes. Excessive small bubbles, especially on the surface, often indicate hemicellulase activity or bacterial overgrowth rather than strong yeast production. Focus on volume gain, not bubble quantity. If it bubbles but doesn’t rise, adjust feeding frequency and flour type.

How long does it take to fix a weak starter?

With correct feeding and temperature, most starters show improved rise within 3–5 days. Full stabilization may take up to 10 days, especially if transitioning from infrequent feeding or poor conditions.

Should I throw away a starter that won’t rise?

Rarely. Most starters can be revived unless contaminated (pink/orange mold, foul sewage smell). More often, the issue lies in care routine, not the culture itself. Only discard if mold appears or if it smells putrid.

Conclusion: Patience and Precision Build a Strong Starter

A bubbling but non-rising sourdough starter isn’t broken—it’s communicating. It tells you that fermentation is happening, but structural strength is missing. With precise feeding, stable warmth, and the right flour, you can transform a sluggish culture into a powerful leavening agent.

The journey to a reliable starter is less about luck and more about observation and adjustment. Track your results, stay consistent, and trust the process. Within a week, you’ll likely see dramatic improvement. And when your starter finally doubles with a domed top and webbed bubbles beneath, you’ll know you’ve built something alive, resilient, and ready to bake with.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?