Concrete is one of the most widely used construction materials in the world due to its compressive strength, versatility, and cost-effectiveness. However, it has a critical weakness: low tensile strength. When subjected to bending, stretching, or shifting forces, plain concrete cracks and fails. This is where rebar—short for reinforcing bar—comes into play. By embedding steel bars within concrete, engineers create a composite material capable of withstanding both compression and tension, making modern infrastructure possible.

Understanding the role of rebar in concrete isn't just relevant for civil engineers and contractors—it's essential knowledge for anyone involved in building design, property development, or even homeowners planning structural renovations. This article explores the science behind rebar use, the types available, best practices for installation, and real-world implications of proper reinforcement.

The Science Behind Concrete’s Weakness and Rebar’s Role

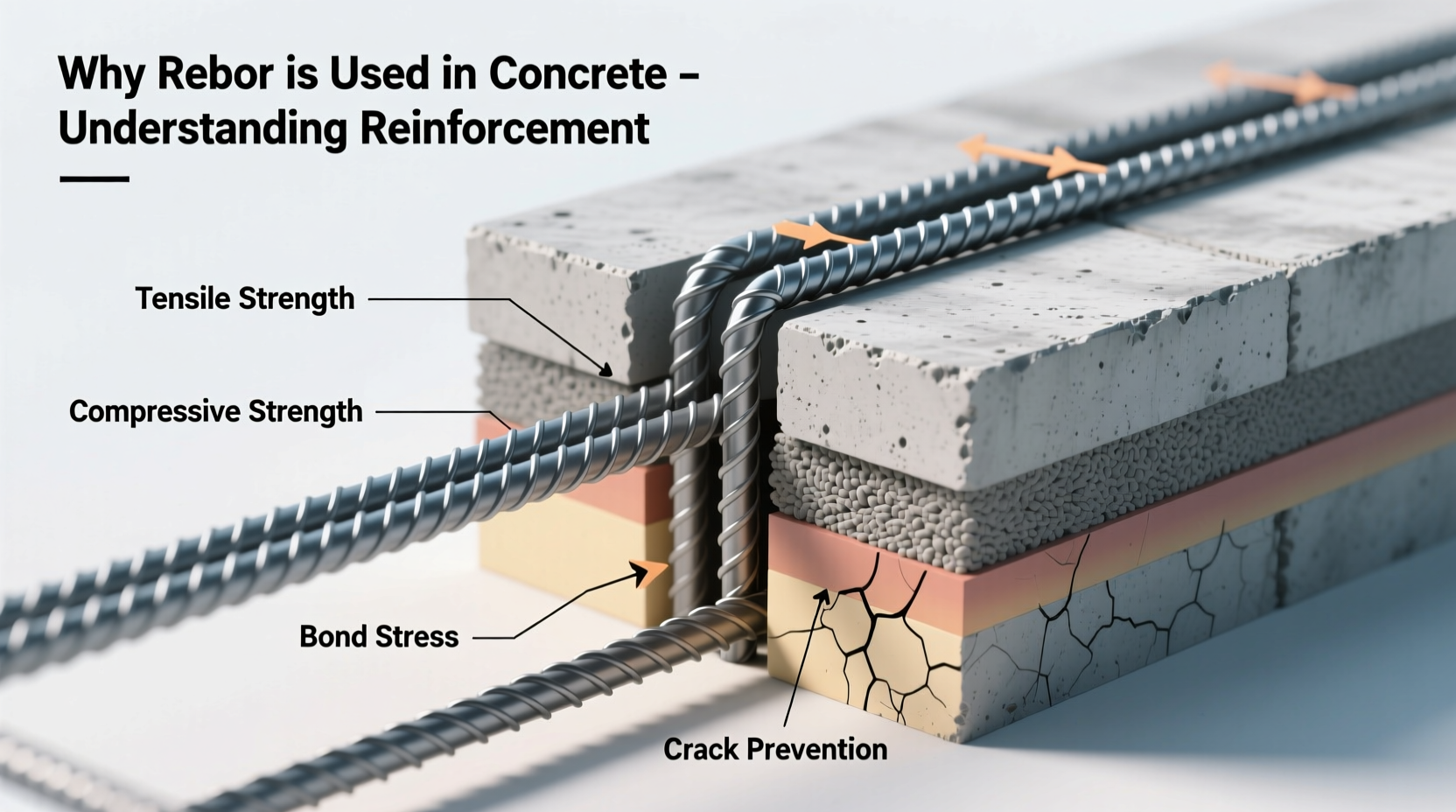

Concrete excels under compressive forces—those that push down or squeeze material together. It can support immense weight, which is why it's ideal for foundations, columns, and slabs. But when forces act to stretch or bend the material (tensile stress), concrete performs poorly. Even minor ground movement, thermal expansion, or load shifts can cause cracks that compromise integrity.

Steel, on the other hand, has excellent tensile strength. When steel reinforcing bars are embedded in concrete before it sets, they absorb tensile stresses, preventing cracks from spreading and maintaining structural continuity. The bond between concrete and steel is strong due to their similar coefficients of thermal expansion—meaning they expand and contract at comparable rates when exposed to temperature changes. This compatibility prevents internal stress buildup over time.

Moreover, concrete provides a protective alkaline environment around the rebar, shielding it from corrosion during the structure’s early life. Over decades, however, moisture and chlorides (from de-icing salts or seawater) can penetrate and initiate rusting—a major concern in long-term durability.

Types of Rebar and Their Applications

Not all rebar is created equal. Different projects demand different reinforcement solutions based on load requirements, environmental conditions, and budget constraints. Below is a comparison of common rebar types:

| Type of Rebar | Material | Key Advantages | Common Uses |

|---|---|---|---|

| Carbon Steel Rebar | Carbon steel with ribbed surface | Inexpensive, strong bond with concrete | Residential buildings, bridges, roads |

| Epoxy-Coated Rebar | Steel coated with epoxy resin | Corrosion-resistant, suitable for wet climates | Marine structures, parking garages, bridge decks |

| Stainless Steel Rebar | High-alloy steel | Extremely durable, highly corrosion-resistant | Critical infrastructure, coastal constructions |

| Glass Fiber Reinforced Polymer (GFRP) | Synthetic composite | Non-conductive, immune to rust | Electromagnetic-sensitive areas, chemical plants |

| Galvanized Rebar | Zinc-coated steel | Better corrosion resistance than plain steel | Humid regions, moderate exposure environments |

The choice of rebar impacts not only performance but also lifecycle costs. While carbon steel remains the most popular due to affordability, high-risk environments justify the higher upfront cost of stainless or composite alternatives.

Best Practices for Installing Rebar in Concrete

Even the highest-quality rebar will fail if not installed correctly. Proper placement, spacing, and anchoring are crucial for optimal performance. Here’s a step-by-step guide to ensure effective reinforcement:

- Design according to structural plans: Rebar size, spacing, and layout must follow engineering specifications based on load analysis.

- Cut and bend bars accurately: Use hydraulic benders or automated systems to achieve precise shapes without weakening the steel.

- Secure with tie wire or mechanical fasteners: Bars should be tied at intersections to maintain position during concrete pouring.

- Maintain proper cover depth: Ensure at least 1.5–2 inches of concrete covers the rebar to protect against fire, weather, and corrosion.

- Inspect before pouring: Conduct a pre-pour inspection to verify alignment, lap lengths, and support stability.

- Use spacers and chairs: These keep rebar elevated and centered within the formwork, preventing contact with soil or forms.

“Reinforcement is only as good as its placement. A misplaced bar can reduce structural capacity by up to 40%.” — Dr. Rajiv Gupta, Structural Engineering Professor, MIT

Real-World Example: The I-35W Bridge Collapse

In August 2007, the I-35W Mississippi River bridge in Minneapolis collapsed during rush hour, killing 13 people and injuring 145. The National Transportation Safety Board (NTSB) investigation revealed multiple factors, including inadequate gusset plates and unexpected additional loads from construction materials. However, a key underlying issue was insufficient reinforcement detailing in certain sections of the deck truss system.

While the collapse wasn’t solely due to poor rebar use, it highlighted how small design oversights—such as undersized steel components and lack of redundancy in tension zones—can lead to catastrophic failure. In response, many U.S. states revised inspection protocols and mandated stricter adherence to reinforcement standards in aging infrastructure.

This case underscores that rebar isn’t just about strength; it’s about resilience, redundancy, and long-term safety. Properly reinforced concrete doesn’t just support weight—it absorbs shocks, resists fatigue, and protects lives.

Common Mistakes and How to Avoid Them

- Insufficient concrete cover: Leads to premature corrosion. Always verify cover thickness using spacers and inspect before pouring.

- Poor lap splicing: Rebar segments must overlap sufficiently (typically 40–60 times the bar diameter) to transfer stress effectively.

- Cross-contamination: Never allow rebar to sit directly on soil or grass; dirt and moisture accelerate rust formation.

- Incorrect bar size substitution: Using smaller bars to cut costs compromises structural integrity and violates building codes.

- Lack of temperature/shrinkage reinforcement: Even non-load-bearing slabs need light mesh or bars to control cracking.

Frequently Asked Questions

Can concrete be strong enough without rebar?

Only in limited cases. Small, non-structural elements like garden paths or shallow slabs with minimal load may not require reinforcement. However, any structure subject to dynamic loads, spanning distances, or exposed to environmental stress should include rebar or alternative reinforcement.

How does rebar prevent cracking?

Rebar doesn’t stop micro-cracks from forming—these are natural in concrete shrinkage—but it holds the cracks tightly closed, preventing them from widening and compromising structural performance. This is known as crack control.

Is rebar recyclable?

Yes. Steel rebar is 100% recyclable. At demolition, it can be extracted and reused in new steel production, making reinforced concrete a relatively sustainable option when deconstruction is planned.

Conclusion: Building Smarter with Reinforced Concrete

Rebar transforms concrete from a brittle, fracture-prone material into a resilient, adaptable building block capable of supporting skyscrapers, highways, and dams. Its integration is not optional in modern construction—it’s fundamental. Understanding why rebar is used, how it functions, and what happens when it’s misapplied empowers builders, designers, and property owners to make informed decisions that impact safety and longevity.

Whether you're overseeing a large-scale project or repairing a basement wall, never underestimate the importance of proper reinforcement. Invest in quality materials, adhere to engineering guidelines, and prioritize correct installation. The strength of your structure depends on it.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?