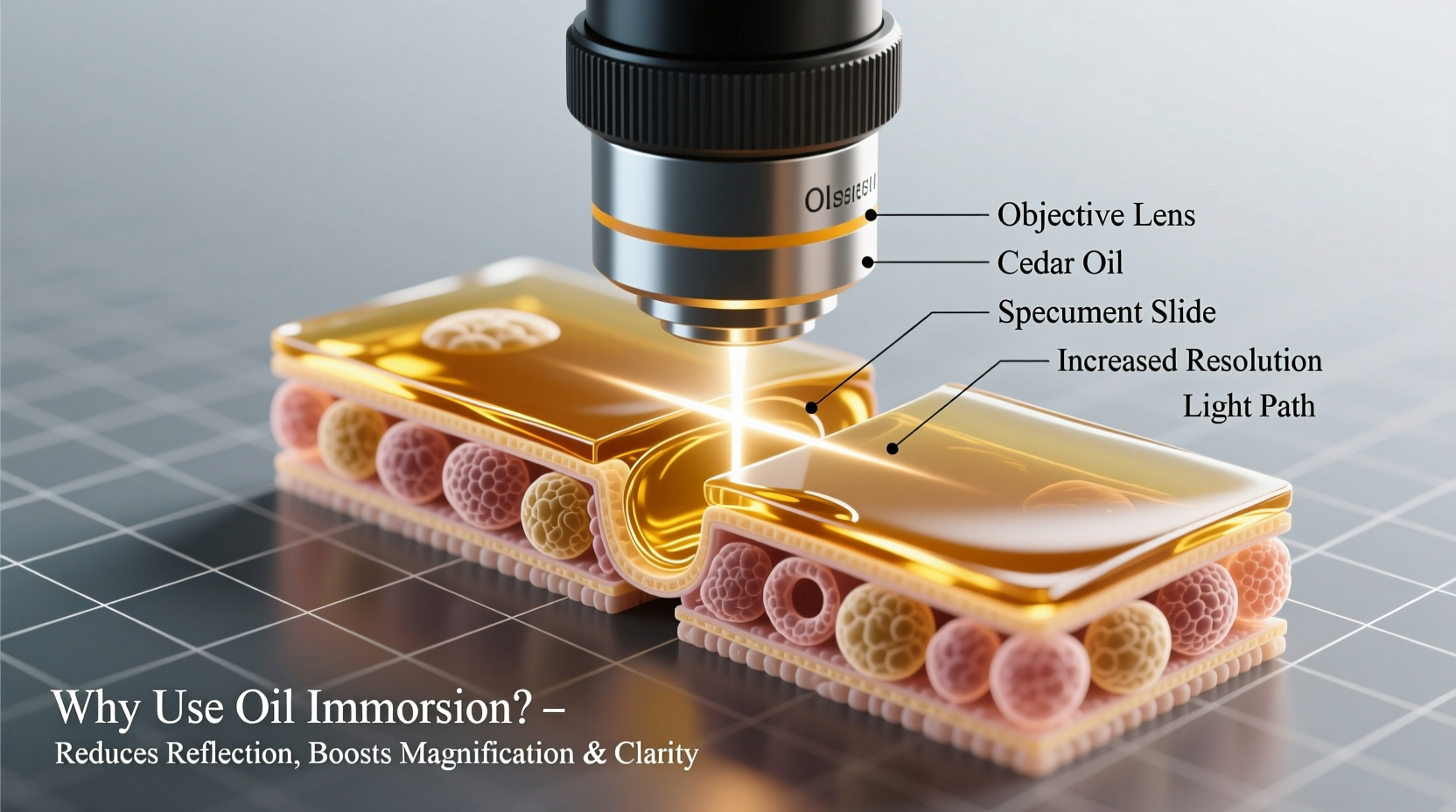

When examining microscopic specimens at high magnifications, clarity and detail are paramount. Yet even with powerful objective lenses, traditional air-based microscopy reaches a physical limit in resolving fine structures. This limitation is overcome through a simple but scientifically profound technique: oil immersion. By placing a drop of specialized immersion oil between the objective lens and the specimen slide, microscopists dramatically improve image resolution and light transmission. Understanding why this works—and when to use it—can transform your ability to observe cellular and subcellular details with precision.

The Science Behind Resolution Limits

In optical microscopy, resolution refers to the smallest distance between two points that can still be distinguished as separate entities. The theoretical maximum resolution is governed by Abbe’s diffraction limit, formulated by German physicist Ernst Abbe in the 19th century. According to this principle, resolution (d) is determined by the wavelength of light (λ) and the numerical aperture (NA) of the lens:

d = λ / (2 × NA)

The numerical aperture itself depends on the refractive index (n) of the medium between the specimen and the lens and the angular aperture (α) of the lens: NA = n × sin(α). In air, the refractive index is approximately 1.0, which limits how much light can be gathered by the objective. As magnification increases—especially beyond 40x—light rays begin to scatter or refract at steep angles, missing the lens entirely and reducing both brightness and sharpness.

This is where immersion oil changes the game. With a refractive index of about 1.515, closely matching that of glass, immersion oil minimizes light refraction and keeps more rays within the lens's acceptance angle. The result? A significant boost in NA—from around 0.95 in dry objectives to over 1.4 in oil-immersion lenses—directly improving resolution by up to 50%.

How Oil Immersion Enhances Image Quality

Beyond increasing numerical aperture, oil immersion improves three key aspects of microscopic imaging:

- Increased Light Collection: Less light is lost to refraction or reflection at the slide-lens interface, resulting in brighter images even at high magnifications.

- Improved Contrast: With more coherent light paths, fine structural differences become easier to distinguish, especially in unstained or phase-sensitive specimens.

- Reduced Spherical Aberration: Mismatched refractive indices cause light rays to focus at different planes. Oil corrects this by creating a uniform optical path from specimen to lens.

These advantages are particularly critical when observing bacteria, spores, organelles, or thin tissue sections where minute morphological features determine identification and analysis accuracy.

“Oil immersion isn’t just a refinement—it’s a necessity if you want to see what’s truly there at 100x. Without it, you’re working below the instrument’s potential.” — Dr. Lena Torres, Microbiology Lab Director, Boston Medical Institute

Step-by-Step Guide to Using Oil Immersion Correctly

Improper use of immersion oil can lead to blurry images, contamination, or lens damage. Follow these steps carefully to ensure optimal results:

- Begin with lower magnification: Focus on your specimen using the 10x or 40x objective to locate the area of interest.

- Rotate the nosepiece halfway: Move the 100x objective close to the slide without engaging it fully.

- Apply a small drop of immersion oil: Place one drop directly onto the coverslip over the focused area.

- Engage the 100x oil objective: Gently rotate the nosepiece so the oil objective enters the oil droplet. Do not force it.

- Refine focus using fine adjustment only: Use minimal movement on the fine focus knob to avoid crushing the slide or submerging the lens too deeply.

- After observation, clean thoroughly: Remove the slide, then wipe excess oil from the lens with lens paper. For residue, use a small amount of xylene or commercial lens cleaner sparingly.

Comparison: Dry vs. Oil-Immersion Objectives

| Feature | Dry Objective (e.g., 40x) | Oil-Immersion Objective (100x) |

|---|---|---|

| Numerical Aperture (NA) | Up to 0.95 | Up to 1.4–1.5 |

| Resolution Limit (at 550 nm) | ~290 nm | ~200 nm |

| Medium Between Lens and Slide | Air (n ≈ 1.0) | Immersion Oil (n ≈ 1.515) |

| Light Transmission Efficiency | Moderate | High |

| Typical Use Cases | Routine histology, basic microbiology | Bacterial morphology, blood smears, detailed cytology |

Real-World Example: Diagnosing Tuberculosis

In clinical laboratories, accurate diagnosis of tuberculosis relies on identifying *Mycobacterium tuberculosis* in sputum smears stained with the Ziehl-Neelsen technique. These rod-shaped bacteria are narrow—often less than 1 µm wide—and appear in clumps or chains. At 40x magnification, they may look like indistinct red streaks. Only under oil immersion at 100x can technicians clearly resolve individual bacilli, confirm their characteristic beaded appearance, and differentiate them from artifacts.

One case at a public health lab in Cape Town demonstrated this decisively. A preliminary report based on dry 40x examination suggested no acid-fast bacilli were present. However, upon switching to oil immersion, dozens of organisms became visible in the same field. This reversal prevented a missed diagnosis and ensured timely treatment initiation. It underscored that skipping oil immersion isn’t merely inconvenient—it can have real clinical consequences.

Frequently Asked Questions

Can I use water instead of immersion oil?

Water has a refractive index of 1.33, closer to air than glass, so it offers little improvement over dry objectives. While water immersion objectives exist—mainly for live-cell imaging—they are designed specifically for aqueous environments and won't perform well with standard slides.

Is oil immersion necessary for all 100x objectives?

Yes. All standard 100x objectives are labeled either “oil” or “oel” (German for oil). Using such an objective without oil will result in poor resolution, hazy images, and reduced contrast due to uncontrolled refraction.

Can immersion oil damage my microscope?

If left uncleaned, yes. Dried oil attracts dust, degrades lens coatings, and may seep into internal components. Always use lens-specific cleaning methods and never substitute non-optical oils like vegetable or silicone oil.

Best Practices Checklist

- ☑ Use only high-quality, non-fluorescent immersion oil

- ☑ Apply only one small drop—excess oil causes spillage and mess

- ☑ Clean the 100x objective immediately after use

- ☑ Store objectives capped and in a dust-free environment

- ☑ Label oil-immersion scopes clearly to prevent misuse

- ☑ Train new users on proper focusing technique to avoid slide breakage

Conclusion: Maximizing the Potential of Your Microscope

Oil immersion is not an outdated relic of classical microscopy—it remains a cornerstone of modern biological and medical research. By aligning optical physics with practical technique, it unlocks the true resolving power of high-magnification lenses. Whether you're analyzing bacterial cultures, studying cell division, or diagnosing disease, skipping oil immersion means accepting blurred, incomplete data. The extra few seconds required to apply oil and clean afterward are a minimal investment for vastly superior results.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?