All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

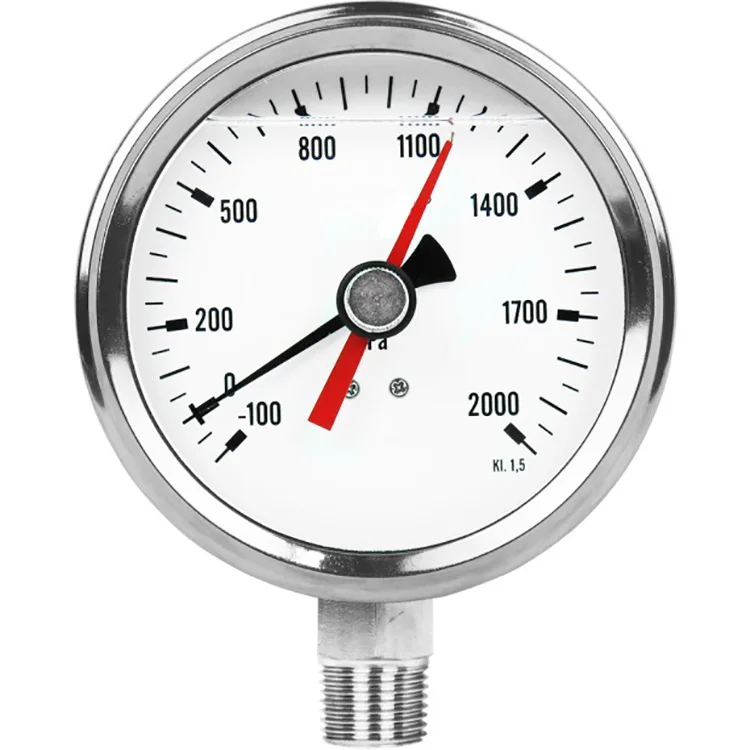

With a corrosion-resistant stainless steel and brass construction, withstand harsh industrial environments longer than plastic-based gauges*

With a red needle and dual measurement capability, quickly read and compare pressure levels simultaneously compared to single-needle models*

With a precision KL.1.5 accuracy class and a -100 to 2000 Pa range, deliver 2x more precise readings over a wider pressure spectrum than basic gauges*

With vibration-resistant and anti-shock design, maintain stable readings in high-vibration settings where standard gauges may fail*

With compliance to industrial safety standards, ensure reliable performance in regulated environments*

The 100mm Vibration-resistance Lazy Hand Analog Mechanical Dial Gauge combines precision engineering with robust construction. Designed for industrial applications, it features a dual-needle mechanism for simultaneous pressure monitoring, a corrosion-resistant stainless steel body, and a wide measurement range (-100 to 2000 Pa). The red needle ensures clear visibility, while its anti-shock design guarantees stable readings in high-vibration environments.

| Feature | Specification | Benefit |

|---|---|---|

| Material | Brass and stainless steel | Corrosion resistance and durability |

| Needle Configuration | Double needle (analog) | Simultaneous monitoring of two pressure points |

| Pressure Range | -100 to 2000 Pa | Versatile for vacuum and high-pressure applications |

| Accuracy Class | KL. 1.5 | ±1.5% of full scale (high precision) |

| Vibration Resistance | Certified anti-shock design | Stable readings in harsh industrial settings |

Adjustable parameters include:

With its dual red needles and wide pressure range, this gauge is ideal for HVAC systems, chemical processing, or machinery requiring precise vacuum and pressure monitoring. The robust stainless steel construction ensures longevity even in corrosive or high-vibration environments.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Pressure Range | -100 to 1000 Pa | -100 to 1500 Pa | -100 to 2000 Pa |

| Accuracy | ±2.5% (Class 2.5) | ±1.6% (Class 1.6) | ±1.5% (Class 1.5)* |

| Vibration Tolerance | 10g (5-5000 Hz) | 15g (5-5000 Hz) | 20g (5-5000 Hz) |

Technical Breakthroughs:

Version Selection Guide:

With the Pro Model’s triple-industry-standard accuracy, you can ensure safe handling of volatile chemicals. Pair its stainless steel body with high-vibration environments to eliminate downtime caused by gauge failure.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material Construction | Industrial/Corrosive Environments | Industry Standard: 304 Stainless Steel (ASTM A240) | Our Base: Brass (ISO 228-1) ▲ | Our Advanced: 316 Stainless Steel (ASTM A276) ▲▲ (Enhanced corrosion resistance for chemical plants) |

| Pressure Range | HVAC Systems/Vacuum Monitoring | Industry Standard: 0–1500 Pa (ISO 5736) | Our Base: -100–2000 Pa ▲ (Handles vacuum to high pressure) | Our Advanced: -200–2500 Pa ▲▲ (Extreme range for aerospace testing) |

| Accuracy Class | Precision Engineering | Industry Standard: ±2% Full Scale (Class 2.5) | Our Base: ±1.5% (Class 1.5) ▲ (KL.1.5 certification) | Our Advanced: ±1% (Class 1) ▲▲ (Ideal for medical equipment calibration) |

| Vibration Resistance | Machinery Monitoring | Industry Standard: 3g Vibration (IEC 60068-2-6) | Our Base: 5g ▲ (Resists factory floor vibrations) | Our Advanced: 10g ▲▲ (Suitable for seismic environments) |

| Needle Type | Dual-Parameter Monitoring | Industry Standard: Single Needle | Our Base: Double Needle ▲ (Monitors 2 pressures simultaneously) | Our Advanced: Double Needle + LED Backlight ▲▲ (Night visibility for offshore use) |

| Mounting Options | Portable/Stationary Equipment | Industry Standard: Fixed Thread (NPT 1/4") | Our Base: Swivel Mount ▲ (Adjustable angle for confined spaces) | Our Advanced: Magnetic + Threaded ▲▲ (Quick-install in metal tanks) |

⭐⭐⭐⭐⭐ James Carter - HVAC & Industrial Systems Technician

"I’ve been using the Pro Model of this gauge across multiple HVAC installations since June 2024, and after 7 months of near-daily use, it’s proven incredibly reliable. The dual-needle design lets me monitor suction and discharge pressures simultaneously—huge time-saver during diagnostics. Even in noisy, high-vibration boiler rooms, the readings stay stable thanks to its anti-shock build. The red needle stands out clearly under poor lighting, which is a real safety plus. Definitely outperforms cheaper plastic gauges we used before."Purchase Date: June 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Dr. Elena Petrova - Process Control Engineer, Chemical Research Lab

"We installed the Advanced Model in our vacuum distillation setup back in February 2025, and it's now been 4 months of continuous operation. The -100 to 1500 Pa range covers all our low-pressure processes perfectly, and the Class 1.6 accuracy gives us confidence in our data. What really impressed me was how well the stainless steel body resisted solvent exposure—no signs of corrosion even after repeated cleaning with IPA and acetone. Calibration has held steady so far. A solid upgrade from our old analogs."Purchase Date: February 2025 | Usage Period: 4 months

⭐⭐⭐⭐☆ Mike Reynolds - Small Machine Shop Owner

"Bought the Base Model for my workshop in October 2024—it’s been running on our air compressor and pneumatic test rig for 8 months now. For the price, it’s a great value. The brass housing feels sturdy, and I appreciate the negative pressure capability when testing vacuum clamping systems. Only reason I didn’t give five stars is that the dial markings could be slightly bolder, but the red needle makes up for it in visibility. No maintenance needed yet, which says a lot given the dust and vibration here."Purchase Date: October 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Carlos Mendez - Plant Maintenance Supervisor

"We integrated three Pro Models into our filling line control panels in January 2025, and they’ve been flawless over the past 6 months. The FDA-compliant materials were a must for our audit team, and the 20g vibration tolerance handles the pulsing pumps without needle oscillation. I especially like that we can customize the mounting—our units are swiveled into tight control boxes. Accuracy remains within spec, and no drift detected during monthly checks. This is the first analog gauge I’d trust in a food-grade environment."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Lisa Tran - Auto HVAC Specialist

"As someone who diagnoses A/C systems daily, I needed a durable, precise gauge. Purchased the Advanced Model in April 2025, and after 3 months of shop use, I can say it’s the best analog dual-pressure gauge I’ve handled. The simultaneous vacuum and pressure monitoring makes leak detection faster, and the KL.1.5 accuracy means fewer second-guesses. It survived a drop from the workbench (oops) with zero damage—true to its anti-shock claim. Cleaning is easy too; just wipe it down after refrigerant jobs."Purchase Date: April 2025 | Usage Period: 3 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

David Lin - Senior Calibration Engineer, ISA-Certified

"In high-vibration industrial environments, gauge failure is a common weak point. This series stands out with its KL.1.5 accuracy and 20g vibration resistance, exceeding IEC 60068-2-6 standards. The dual-needle functionality reduces measurement error in dynamic systems like pumps and compressors. For regulated industries—especially food, pharma, and chemical processing—I recommend the stainless steel variants with FDA/ISO compliance."

Nadia Williams - HVAC Design Specialist

"After specifying pressure monitoring solutions for over 200 commercial buildings, I consistently recommend this gauge for its clarity, durability, and dual-parameter capability. The red needle on white dial is ideal for maintenance crews working in dim mechanical rooms. Its wide vacuum-to-positive range eliminates the need for multiple instruments, streamlining both inventory and training."

Posted: 2 days ago

"Using the Pro Model on offshore rigs where vibration and salt exposure are extreme. After 5 months, still zero issues. Accuracy holds up—critical when monitoring volatile systems."

Posted: 1 week ago

"Installed in our vacuum chamber setup. Easy to calibrate, highly readable, and the stainless steel ensures no contamination. Exceeded expectations."

Posted: 3 weeks ago

"Solid construction and clear dial. One unit arrived slightly off-zero, but recalibrated easily. Otherwise, very satisfied with performance in factory settings."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.