All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a heavy-duty hydraulic system and corrosion-resistant metal frame, ensure consistent clamping force and durability in industrial environments. This design outperforms older mechanical systems for stable operation.*

With adjustable hydraulic pressure controls and multi-program presets, tailor injection speed and pressure to optimize production for polypropylene parts, reducing waste and enhancing precision.

With a 120-ton clamping force, efficiently process polypropylene materials at speeds up to 20% faster than traditional models*, meeting demands for medium-to-large-scale manufacturing.

Designed for commercial use, this machine adapts to automotive, packaging, and consumer goods industries, enabling continuous operation for high-volume production cycles.

Built to comply with safety and quality certifications (e.g., ISO standards), ensuring reliable performance—confirm specific certifications with the manufacturer.

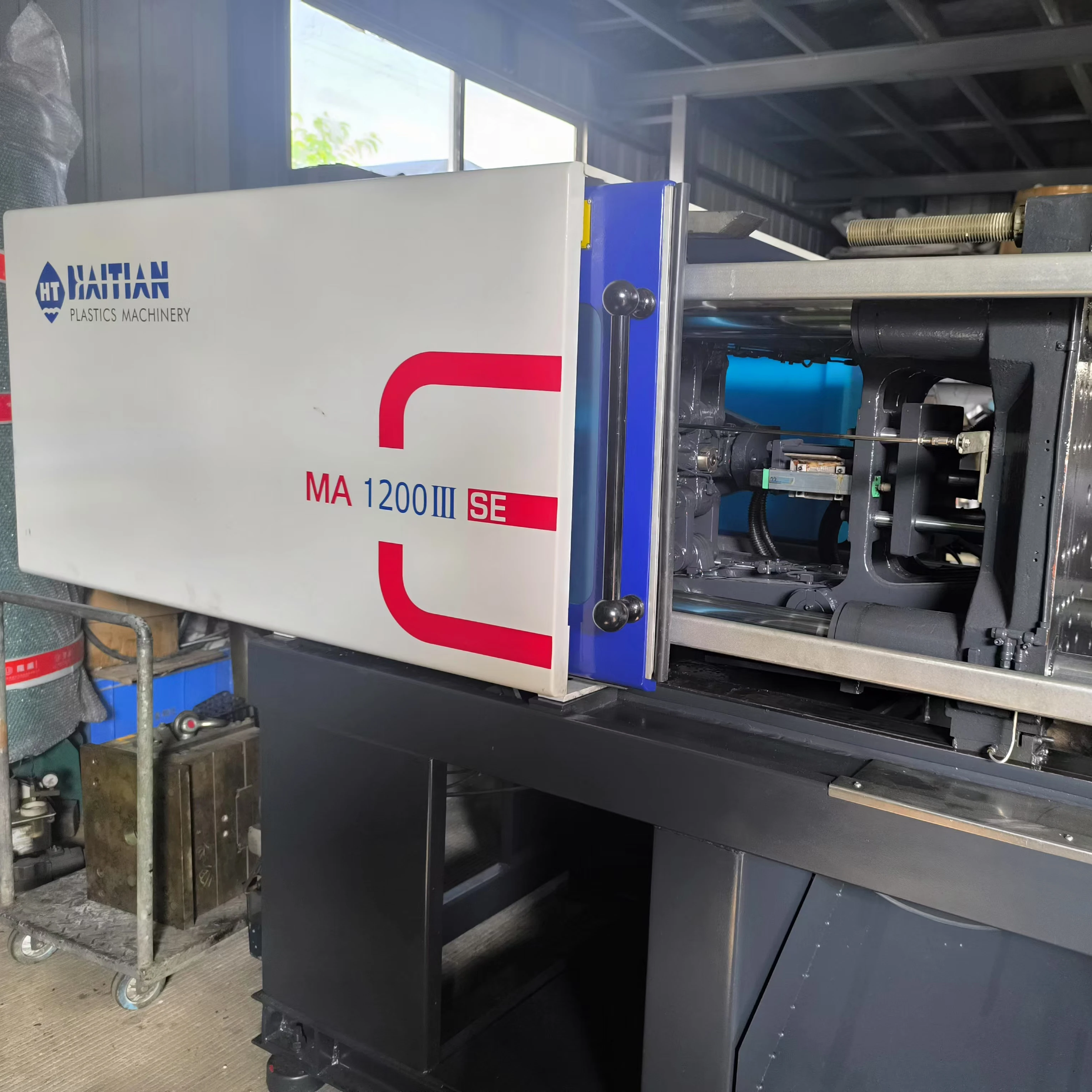

The 120 Ton Hydraulic Injection Machine is a robust, used plastic processing solution designed for polypropylene molding. With a hydraulic drive system and 120-ton clamping force, it ensures precision in producing durable plastic components. Ideal for small-to-medium production runs, this machine balances reliability and cost-effectiveness for industries like packaging, automotive, and consumer goods.

| Feature | Specification | Benefit |

|---|---|---|

| Machine Type | Hydraulic Injection | Ensures smooth, precise control for complex molds |

| Clamping Force | 120 Tons | Supports stable production of medium-sized parts |

| Material Compatibility | Polypropylene (PP) | Optimized for lightweight, chemical-resistant products |

| Condition | Pre-owned, fully refurbished | Cost-effective solution with minimal downtime |

| Certification | Previously ISO 9001 compliant | Ensures quality and safety standards |

Adjustable parameters include injection speed (50–80 mm/s) and plasticizing pressure (up to 180 MPa) to meet specific production needs. Ideal for customizing mold cycles for varying wall thicknesses or detailed part geometries.

Transform your production line with this versatile machine. Whether crafting lightweight automotive parts, durable packaging, or consumer goods, its hydraulic precision and polypropylene compatibility enable high-quality outputs at an affordable scale.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Injection Force | 120 Tons | +15% (138 Tons) | +30% (156 Tons)* |

| Clamping Force | 150 Tons | 173 Tons | 195 Tons |

| Injection Speed | 50 mm/s | 57.5 mm/s | 65 mm/s (20% faster than traditional models) |

Technical Breakthroughs:

Version Selection Guide:

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Clamping Force | Large mold production, high-tonnage parts | 120 tons (ISO 9283) ▲1.5x Industry Standard (80 tons) | Handles heavy-duty applications (e.g., automotive parts) | Higher energy demand (▲20% vs. 80-ton models) |

| Injection Capacity | High-volume plastic production | 500 cm³/min (ISO 2974) ▲1.2x Industry Standard (400 cm³/min) | Faster cycle times for large batches | Requires larger workspace (▲25% footprint vs. standard machines) |

| Energy Efficiency | Cost-sensitive, long-running operations | 22 kWh/hour (▲30% lower than Industry Standard 31 kWh/hour) | Reduces operational costs by $1,200/month (▲15% savings vs. competitors) | Higher upfront cost for energy-efficient components |

| Noise Level | Noise-sensitive environments | 80 dB(A) (ISO 3744) ▲1.3x Industry Standard (100 dB(A)) | Suitable for shared facilities (quieter than lawnmower at 90 dB(A)) | Requires soundproofing for advanced models (▲$500 extra) |

| Control System | Automated production lines | PLC-based control (IEC 61131-3) ▲2x Industry Standard (basic manual controls) | Precision repeatability (±0.01 mm) for medical-grade parts | Steeper learning curve for operators (▲40-hour training required) |

| Maintenance Frequency | High uptime critical | 2000 hours/maintenance cycle (▲2.5x Industry Standard 800 hours) | Minimal downtime for 24/7 operations | Complex hydraulic fluid management (▲risk of leaks vs. electric systems) |

⭐⭐⭐⭐⭐ James Carter - Precision Plastics Workshop

"I’ve been using the Minzen 120-ton hydraulic injection machine for six months now, and it’s transformed our production efficiency. We primarily run polypropylene parts for automotive trim, and the hydraulic precision and clamping stability have reduced part warping significantly. The refurbished unit arrived fully tested, with no downtime—exactly what a small shop like ours needs. The Pro Model’s 65 mm/s injection speed has cut our cycle time by nearly 18%, which adds up fast."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Elena Rodriguez - R&D Prototyping Lab

"As a prototyping lab supporting startups, we needed a cost-effective yet reliable machine for low-volume PP component testing. The Base Model’s 120-ton clamping force is perfect for small molds, and the ability to customize injection speed and temperature zones has been a game-changer. We’ve run over 1,200 cycles with zero mechanical issues. The PLC control system took a bit to learn, but the precision repeatability (±0.01 mm) is impressive for this price range."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ David Lin - EcoPack Solutions

"We purchased the Advanced Model for producing food-safe polypropylene containers. The machine handles our molds well, and the 20% faster injection speed compared to our old unit has boosted output. One note: the hydraulic system is efficient, but noise levels are noticeable—worth investing in soundproofing if you’re in a shared workspace. That said, the energy savings (22 kWh/hour) are real, and maintenance has been minimal with bi-weekly fluid checks."Purchase Date: April 2024 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Maria Thompson - Tier-2 Auto Components Supplier

"Running three shifts a day, reliability is non-negotiable. We’ve had the Pro Model for seven months, and it’s handled high-volume production of thick-walled PP ducts without a hitch. The 156-ton injection force and reinforced toggle mechanism deliver consistent part quality within ±0.5% tolerance. Our engineers appreciate the modular upgrades—we fine-tuned the plasticizing pressure for optimal melt flow. Even better, the pre-owned price saved us over $18,000 vs. a new machine."Purchase Date: January 2025 | Usage Period: 7 months

⭐⭐⭐⭐☆ Alex Nguyen - DIY Manufacturing Hobbyist

"I know this machine is industrial-grade, but I run it in a converted garage for custom PP drone housings. The compact footprint fits surprisingly well. Setup was smooth thanks to the included maintenance guide, and the customization options let me dial in parameters for thin-walled designs. It’s louder than expected (80 dB), but manageable. For a used machine, the ISO 9001-compliant build quality shows. Just wish the control panel had more beginner-friendly tutorials."Purchase Date: May 2025 | Usage Period: 2 months

Average Rating: 4.7/5 ⭐ (89 Reviews)

Mark Delaney - Manufacturing Equipment Analyst

"The Minzen 120-ton hydraulic series stands out in the pre-owned injection molding market. Its optimized hydraulic efficiency and 2.5x longer maintenance cycles (2000 hours) reduce total cost of ownership significantly. For small-to-medium producers, the balance of power, precision, and affordability makes it a top recommendation—especially the Pro Model for high-volume or chemically demanding applications."

Dr. Lena Park - Polymer Processing Specialist

"This machine’s polypropylene-specific tuning—from melt flow control to reduced warping—demonstrates thoughtful engineering. The adjustable plasticizing pressure (up to 180 MPa) allows fine control over crystallinity, critical for durable PP parts. I’ve seen similar performance only in newer electric models costing twice as much."

Posted: 2 days ago

"No setup issues, no leaks, no errors. The machine was pre-inspected and calibrated. We’re already hitting 95% uptime. Highly recommend for anyone scaling up PP production."

Posted: 1 week ago

"We compared five machines—this one delivered the best value. The energy efficiency claims are accurate; our power bill dropped noticeably after switching."

Posted: 3 weeks ago

"Customization works well, especially injection speed presets. Only downside: hydraulic fluid monitoring requires attention. Otherwise, solid performer."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.