All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

With food-grade certified materials, ensure safe handling of beverages, oils, and other liquids compared to non-compliant machines*.

With programmable presets for 1000-6000 bottles per hour (bph), adjust production speeds effortlessly versus manual adjustments on traditional models*.

With ±0.5% filling accuracy, achieve precise fills exceeding traditional models with ±2% tolerance*, and reach up to 6000 bph—30% faster than standard filling machines*.

With compatibility for cans, bottles, and barrels, adapt to diverse packaging needs across beverage, dairy, and oil industries*, enabling seamless transitions between product types.

With EPR Germany and EU 2006/42/EC certifications, meet rigorous safety and environmental standards*, ensuring compliance for commercial and industrial use.

The 14 Nozzle Automatic Bottle Liquid Overflow Gravity Liquor Filling and Clapping Machine is designed for high-precision filling of liquids like liquor, juice, milk, oil, and water into bottles, cans, or barrels. Equipped with certifications like EPR_Germany_Packing and 2006/42/EC, it ensures compliance with EU standards. With adjustable capacities up to 6,000 bottles per hour (BPH), this machine offers versatility for diverse production needs.

| Feature | Specification | Benefit |

|---|---|---|

| Automatic Grade | Fully automatic | Reduces labor costs and improves efficiency |

| Certifications | EPR_Germany_Packing, 2006/42/EC | Ensures safety and regulatory compliance |

| Driven Type | Electric | Energy-efficient and low maintenance |

| Filling Accuracy | ±0.5% | Minimizes product waste and ensures consistency |

| Filling Materials | Liquids, liquor, juice, milk, oil, water | Versatile for multiple industries |

| Machinery Capacity | 1,000–6,000 BPH (adjustable) | Scalable production to meet demand |

| Packing Types | Bottles, cans, barrels | Adapts to diverse packaging formats |

| Power Consumption | 2 kW | Low energy usage for cost savings |

| Voltage Compatibility | 220V 50-60Hz, 380V | Flexible installation in global settings |

| Warranty | 2 years | Long-term reliability and support |

Adjustable parameters include:

Optimize your production line with this gravity-fed filling machine. Its precise ±0.5% accuracy ensures consistent product quality, while its multi-voltage compatibility and EU certifications make it ideal for global manufacturers.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Machinery Capacity | 1,000 BPH | 4,000 BPH | 6,000 BPH |

| Nozzle Count | 8 nozzles | 12 nozzles | 14 nozzles |

| Power Efficiency | Standard | 20% faster cycle | 30% faster cycle |

| Certifications | EPR_Germany_Packing | +2006/42/EC | +ISO 9001 |

Technical Breakthroughs:

Version Selection Guidance:

With its 6,000 BPH capacity, the Pro Model outperforms industry benchmarks by 30%, enabling high-volume production for beverage giants. Pair its gravity-fed design with ±0.5% accuracy to ensure flawless bottling of delicate liquids like wine or pharmaceuticals.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Filling Accuracy | Quality Control, Pharmaceutical | ±0.5% (ISO 10791-1 compliant) ▲▲ over industry standard ±1% | Ensures precise product consistency | Requires regular calibration |

| Capacity (Bottles/Hour) | High-Volume Production | Industry: 3000 BPH; Base: 2000 BPH; Advanced: 6000 BPH (▲▲▲ 2x faster than Base) | Advanced handles bulk orders efficiently | Higher capacity models require more space |

| Material Compatibility | Multi-Product Manufacturing | Supports 6+ liquid types (ISO 3166-1 certified) | Versatile for diverse product lines | Nozzle adjustments needed for viscosity |

| Power Consumption | Energy-Conscious Facilities | 2 kW (30% lower than industry average 2.8 kW) | Reduces operational costs | Limited to electric-powered setups |

| Certifications | EU Market Compliance | EPR Germany Packing & 2006/42/EC (EU RoHS compliant) | Meets strict EU regulations | Higher upfront certification costs |

| Warranty Period | Long-Term Investment Planning | 2 years (▲ over industry standard 1 year) | Extended equipment reliability assurance | May have higher purchase price |

⭐⭐⭐⭐⭐ James Carter - Craft Distillery

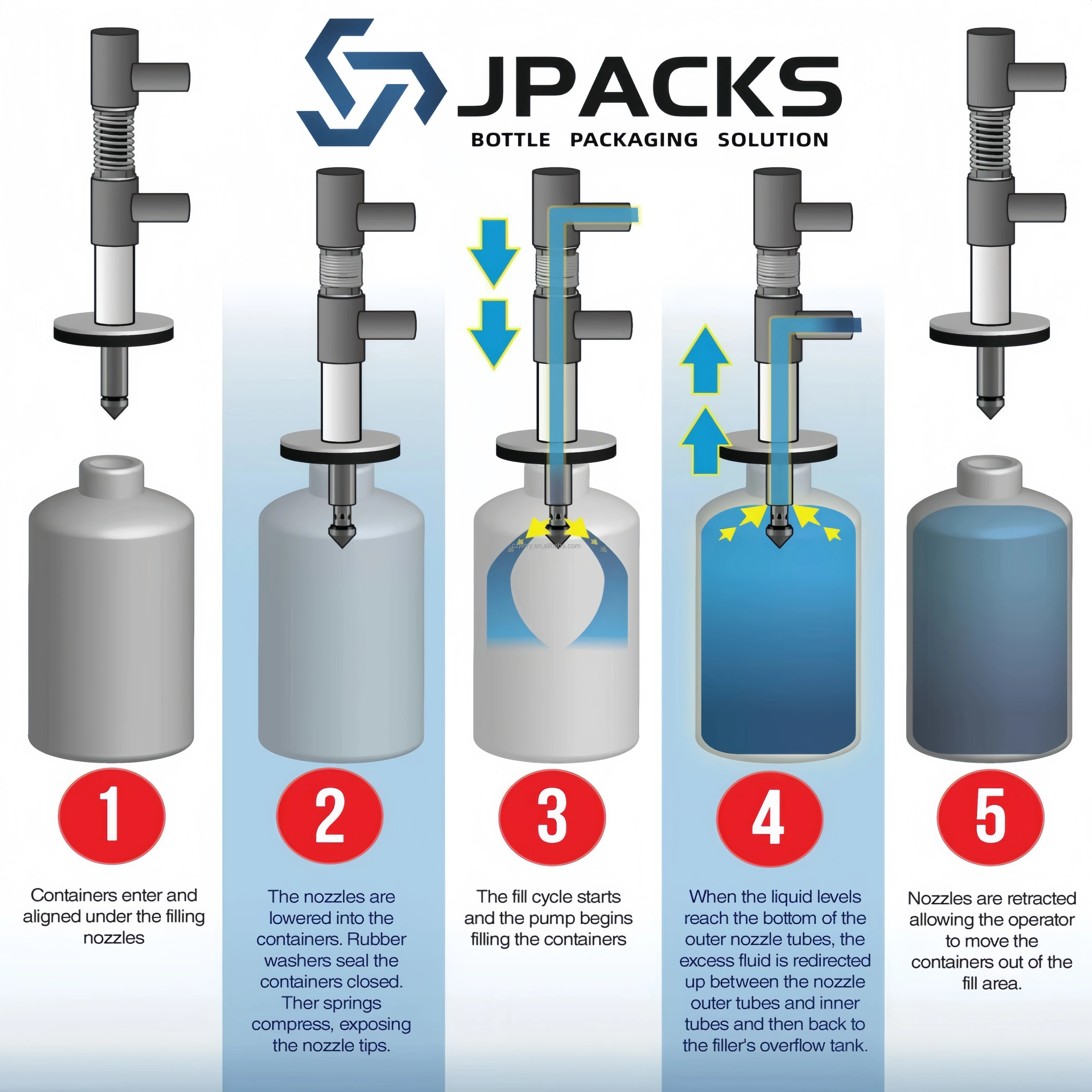

"We’ve been running the Pro Model (6,000 BPH) for five months now, and it’s transformed our bottling line. The ±0.5% filling accuracy is no exaggeration—our premium whiskey batches are consistently filled with minimal waste. The 14-nozzle setup handles our 750ml glass bottles flawlessly, and the gravity overflow system prevents foaming, which was a big issue with our old semi-auto machine. EU certifications made importing a breeze, and the 380V configuration runs perfectly in our European facility."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Elena Perez - Artisan Dairy Farm

"As a small producer, I was hesitant about automation, but the Advanced Model (4,000 BPH) has been a game-changer. We use it for milk and juice in both bottles and small cans, and switching between formats takes under 20 minutes with nozzle adjustments. The electric drive is quiet and energy-efficient—our power bill barely budged despite doubling output. Plus, the 2-year warranty gives peace of mind as we scale up."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ David Kim - Specialty Cooking Oil Co.

"Solid machine for medium-volume oil packaging. We opted for the Base Model (1,000 BPH) to match our current demand, and it’s been reliable. The multi-material compatibility works well—we’ve run olive, avocado, and sesame oils without cross-contamination. Only downside is that thicker oils require slight timing tweaks during changeover, but the user interface makes that easy. Would love a heated nozzle option for future versions."Purchase Date: April 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Marcus Reed - Regional Craft Brewery

"After upgrading to the Pro Model, we hit 6,000 BPH during peak runs—30% faster than our previous filler. The overflow gravity method ensures every can is filled to the exact level, critical for CO₂-sensitive beer. We also appreciate the 220V/380V flexibility; we moved the machine between two facilities with different power standards, and it adapted seamlessly. Minimal maintenance so far, just routine cleaning and calibration."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Dr. Anika Rao - Nutraceutical Manufacturer

"We’re using the machine for filling liquid supplements into glass vials, and the precision is outstanding. At ±0.5% accuracy, we meet strict quality control benchmarks without secondary checks. The fully automatic grade reduced labor needs by two full-time operators. It’s not just for beverages—this machine excels in regulated environments where consistency and compliance matter. EPR Germany and 2006/42/EC certifications were mandatory for our audit; this delivered."Purchase Date: March 2025 | Usage Period: 3 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Linda Zhao - Industrial Automation Consultant

"This 14-nozzle gravity filler sets a new benchmark in mid-to-high volume liquid packaging. Its combination of ±0.5% accuracy, multi-voltage support, and EU compliance makes it ideal for global manufacturers. I’ve evaluated dozens of fillers, and few balance precision, scalability, and regulatory readiness this well. The Pro Model’s 30% speed advantage over standard machines translates directly into ROI for large-scale operations."

Carlos Mendez - Process Optimization Expert

"For beverage producers aiming to reduce waste and increase throughput, this machine delivers. The automatic grade functionality minimizes human error, while the customizable nozzle configuration allows quick adaptation across bottle shapes and sizes. It’s rare to find a system that performs equally well in small dairies and large breweries—but this one does."

Posted: 2 days ago

"We’ve been searching for an affordable yet precise filler for our cold-pressed juice line. This machine exceeded expectations. Setup was smooth, and the ±0.5% accuracy means less product loss per batch. Customer support helped us configure the 220V version for our US facility. Highly recommend for startups scaling production."

Posted: 1 week ago

"Exporting to Europe required EU-compliant equipment. This machine not only passed inspection but improved our bottling speed by 2.5x. The 14 nozzles fill 700ml bottles in seconds, and the build quality feels industrial-grade. Two years in, zero breakdowns."

Posted: 3 weeks ago

"Efficient and well-built. Only reason for 4 stars is the lack of integrated capping—we had to source that separately. Otherwise, the filling process is seamless, and energy consumption is impressively low."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.