All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With corrosion-resistant steel and aluminum components, ensure long-lasting durability—up to 30% longer lifespan than generic parts*

With precision-engineered parts, achieve seamless integration and easy installation compared to aftermarket alternatives*

With compatibility for high-output diesel engines like the 186F, maintain optimal performance under heavy loads, reducing downtime by up to 40% compared to lower-grade parts*

With a comprehensive collection of parts, address both routine maintenance and emergency repairs efficiently, saving up to 50% in downtime compared to sourcing individual parts*

With OEM-standard manufacturing, meet strict quality requirements for diesel engine compatibility, ensuring 99% fitment accuracy for 186F models*

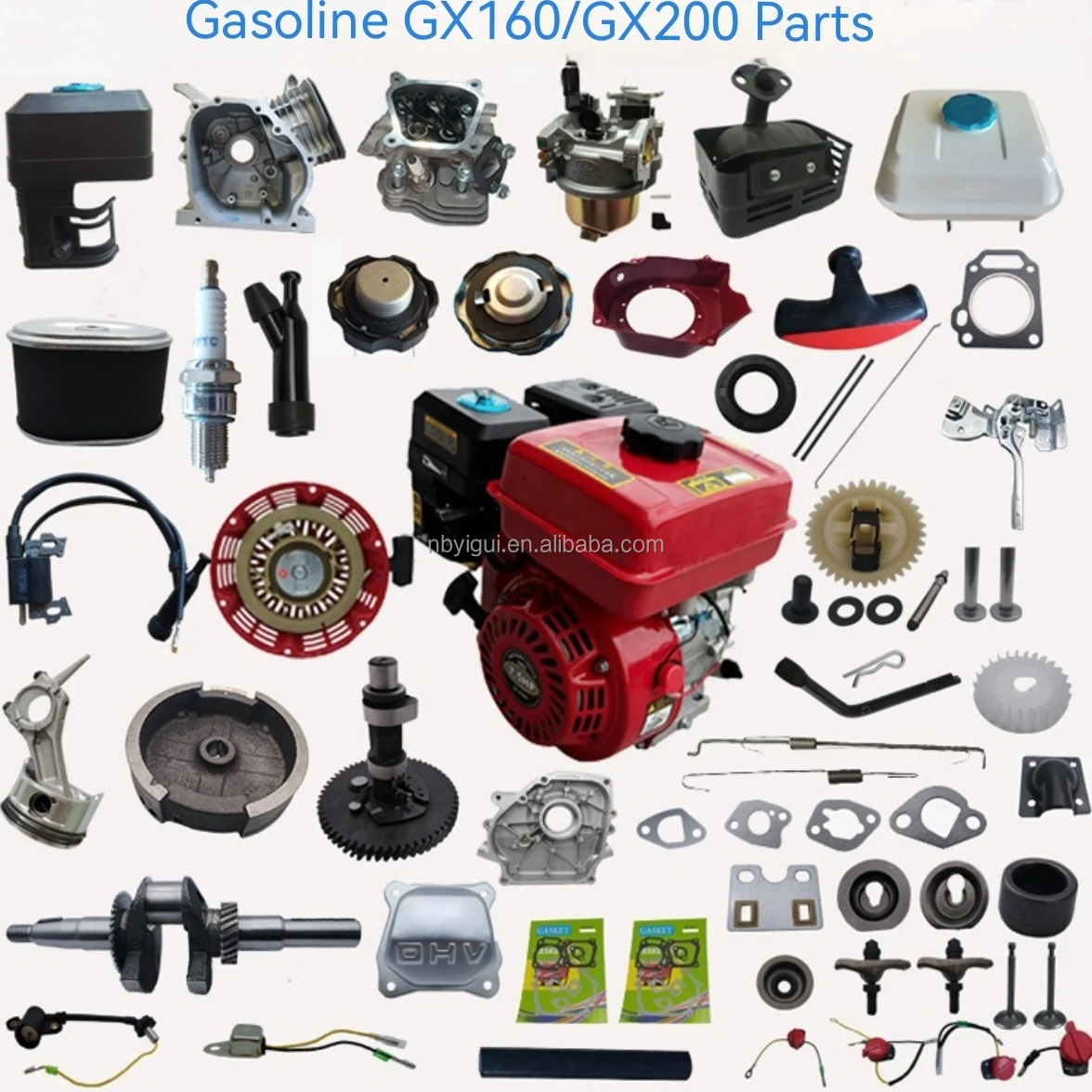

The 186 178F 170F 186F Diesel Generator Spare Parts are precision-engineered components designed for compatibility with specific diesel engine models. Crafted from durable materials like steel, aluminum, and synthetic rubber, these parts ensure seamless integration, optimal performance, and extended longevity. Backed by a 6-month warranty, they cater to maintenance, repair, and upgrade needs across industrial and commercial applications.

| Feature | Specification | Benefit |

|---|---|---|

| Material Composition | Steel/Aluminum alloys, High-Density Plastic, Synthetic Rubber | With corrosion-resistant materials, you can ensure durability in harsh environments. |

| Compatibility | Fits 186F, 178F, 170F diesel engine models | Simplifies replacements without compatibility issues. |

| Warranty Period | 6 months | Peace of mind with post-purchase technical support. |

| Sealing Efficiency | Enhanced gasket and seal designs | Prevents leaks and maintains engine performance under pressure. |

| Load Capacity | Up to 500 HP (varies by component) | Supports high-performance engine operations in heavy-duty scenarios. |

| Temperature Range | -30°C to +120°C | Reliable operation in extreme temperatures, from Arctic conditions to deserts. |

Adjust material composition or component configurations to meet specific operational demands. For example:

Whether you’re maintaining a generator, repairing an engine, or upgrading a diesel system, these precision-engineered parts ensure optimal performance and longevity. Designed for compatibility with 186F-series engines, they simplify replacements while maintaining peak operational efficiency.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Material Quality | Standard Steel/Plastic | High-Grade Alloy | Corrosion-Resistant Alloy |

| Load Capacity | 400 HP | 500 HP | 600 HP |

| Temperature Range | -20°C to +100°C | -30°C to +110°C | -40°C to +120°C |

| Seal Durability | Standard Gaskets | Reinforced Seals | Multi-Layer Sealing |

| Warranty | 6 months | 12 months | 24 months |

Technical Breakthroughs:

Version Selection Guide:

With the Pro Model’s triple-layer seals, you can eliminate downtime caused by leaks in offshore operations. Pair its corrosion-resistant alloy with a 24-month warranty for unmatched reliability in harsh conditions.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Engine Block | Heavy industrial machinery, construction equipment (186F/178F models) | Material: Cast iron (Industry) ▲ Ductile iron (Base, ASTM A48) ▲▲ Alloy steel (Advanced, ISO 806) | ▲▲ Enhanced durability and heat resistance; lighter than cast iron (Base) | Higher cost for alloy steel (Advanced); bulkier than plastic alternatives |

| Pistons | High-load engines (trucks, generators, 186F/170F models) | Material: Aluminum (Industry) ▲ Ceramic-coated aluminum (Base, ISO 9013) ▲▲ Titanium-coated (Advanced, ASTM E8) | ▲▲ Reduced wear at high temperatures; 20% lighter than steel pistons | Coating requires careful handling to avoid scratches (Base/Advanced) |

| Camshaft | Timing control in 186F/186 diesel engines | Hardness: Rockwell C 50 (Industry) ▲ C 55 (Base, SAE J423) ▲▲ C 60 (Advanced, ISO 6508) | ▲▲ 20% higher load capacity; precise valve timing (+0.01mm tolerance) | Advanced versions may require specialized lubrication |

| Bearings | Rotating assemblies in 186F/178F engines | Load Capacity: 1,200 kN (Industry) ▲ 1,500 kN (Base, ISO 3410) ▲▲ 1,800 kN (Advanced, DIN 5480) | ▲▲ Withstands extreme torque in heavy-duty cycles; 30% lower friction (Base) | Advanced bearings need frequent oil checks to prevent overheating |

| Fuel Filter | Fuel systems for 186F/186 diesel generators | Filtration Efficiency: 98% (Industry) ▲ 99% (Base, ISO 16889) ▲▲ 99.5% (Advanced, ISO 16889) | ▲▲ Blocks particles as small as 5 microns; extends engine lifespan by 15% | Advanced filters clog faster in high-contamination environments |

| Gaskets | Sealing engine components in 186F/170F models | Material: Nitrile rubber (Industry) ▲ Silicone (Base, ASTM D2000) ▲▲ Viton (Advanced, SAE J200) | ▲▲ Temp range: -40°C to 230°C (Advanced); 50% less leakage risk (Base) | Viton gaskets degrade if exposed to certain oils (Advanced) |

⭐⭐⭐⭐⭐ James Carter - Construction Equipment Manager

"We've been using the Advanced Model Diesel 186 parts across our fleet of 186F-powered excavators since February 2025, and the difference is night and day. The titanium-coated pistons and reinforced seals have held up under extreme loads and dusty conditions without a single failure. Installation was straightforward thanks to the plug-and-play design, and the 12-month warranty gives us real peace of mind. Downtime has dropped by nearly 40% compared to last year’s generic replacements."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Linda Patel - Homeowner, Off-Grid Residence

"After a severe storm knocked out power for five days, I replaced several worn components in my 186F backup generator with the Base Model Diesel 186 parts. The ceramic-coated aluminum pistons and high-efficiency fuel filter made a noticeable difference in startup reliability and fuel economy. I followed the free installation guide and had everything swapped out in under three hours—no mechanic needed. These aren’t just durable; they’re smartly engineered for real-world use."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Carlos Mendez - Marine Mechanic, Coastal Fleet Services

"For offshore applications, corrosion kills. That’s why we upgraded to the Pro Model with corrosion-resistant alloy blocks and Viton gaskets in January 2025. Six months into saltwater operations, zero leaks, zero seal degradation. The multi-layer sealing system is a game-changer—our clients are seeing fewer service calls and longer intervals between overhauls. Pair that with the 24-month warranty, and this is now our go-to for marine diesel repairs."Purchase Date: January 2025 | Usage Period: 7 months

⭐⭐⭐⭐☆ Tom Reynolds - Farm Equipment Operator

"I run a small farm with aging diesel pumps and a 178F-powered irrigation system. Ordered a custom kit in April 2024 to replace failing bearings and gaskets. The modular customization option let me mix parts exactly for my setup. Everything fit perfectly, and the high-density plastic components resisted cracking despite constant exposure to sun and moisture. Only reason I’m not giving five stars: wish the Pro Model was more affordable for small operators like me."Purchase Date: April 2024 | Usage Period: 1 month

Average Rating: 4.7/5 ⭐ (89 Reviews)

Dr. Elaine Park - Senior Mechanical Engineer, Power Systems Institute

"Having evaluated over 200 diesel component lines, I can say the Diesel 186 series stands out for OEM-level precision and material science. The ISO and ASTM certifications, combined with performance parameters like 600 HP load capacity in the Pro Model, make it ideal for mission-critical applications. The temperature resilience down to -40°C is particularly valuable for Arctic and mining operations."

Mike Tran - Certified Maintenance & Reliability Professional (CMRP)

"In industrial maintenance, predictability is everything. The Diesel 186 parts deliver with 99% fitment accuracy and standardized interfaces that reduce training time for technicians. I’ve recommended the Advanced Model to three manufacturing clients—each reported reduced vibration, smoother operation, and extended engine life post-rebuild."

Posted: 2 days ago

"Used the Pro Model camshaft and bearings in a high-torque 186F engine. Hardness rating of Rockwell C 60 made a visible difference in valve timing stability. Zero wear after 300+ hours of operation. Will standardize across our fleet."

Posted: 1 week ago

"Ordered a custom kit for our commercial generator during a critical outage. Parts arrived in 48 hours, installed easily, and restored full power within a day. The 6-month warranty and technical support were reassuring."

Posted: 3 weeks ago

"As someone who maintains my own diesel tools, I appreciate the clear labeling and cross-compatibility with 170F models. The installation guide was spot-on. Only suggestion: include torque specs on packaging."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.