All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

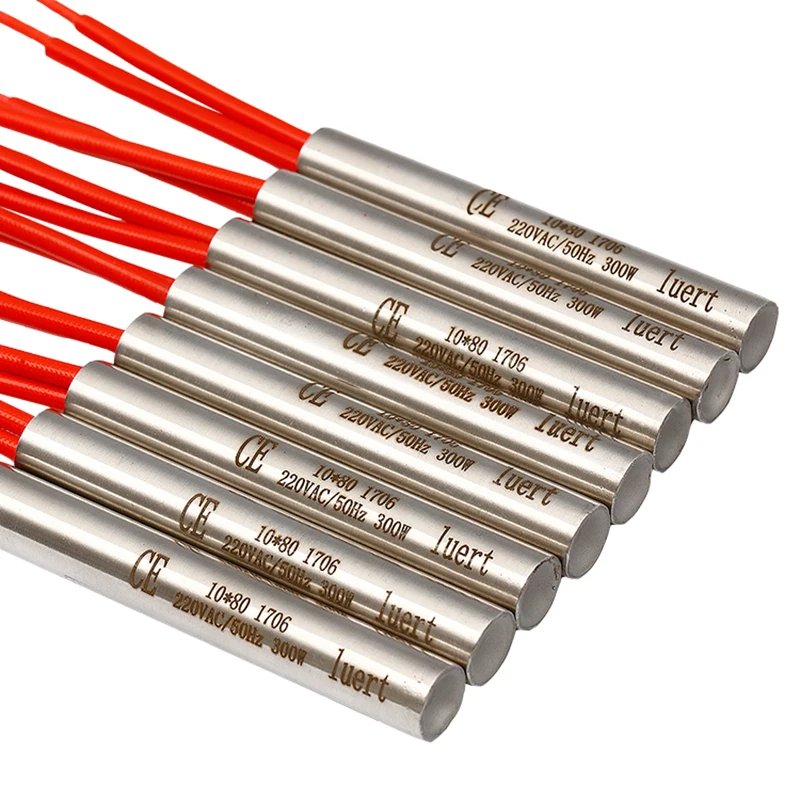

With corrosion-resistant stainless steel construction, ensure reliable operation in harsh industrial environments.

With a threaded mounting design, easily integrate into heating systems for secure and stable operation.

With power outputs ranging from 80W to 1000W, adapt to diverse heating demands across industries.

Engineered for industrial applications like plastic injection molding, deliver precise temperature control for consistent results.

Constructed to meet industrial safety standards for high-temperature applications, ensuring reliable performance.

The 2021 China Electric Heating Rod Heating Elements are robust, versatile heating solutions designed for industrial and commercial applications. Constructed from high-quality steel and stainless steel, these heaters deliver precise temperature control and durability, with power options ranging from 80W to 1000W to suit diverse heating needs. Their cylindrical rod shape and threaded ends ensure secure mounting, while the 1-year warranty guarantees reliability.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material | Stainless Steel / Steel | Harsh environments (e.g., corrosive chemicals, high temperatures) |

| Power Range | 80W – 1000W | Customizable heating for labs, manufacturing, or home appliances |

| Power Source | Electric | Plug-and-play compatibility with standard electrical systems |

| Shape | Rod (cylindrical with threaded ends) | Secure integration into heating blocks or machinery |

| Type | Air Heater, Electric Heater | Industrial processes (plastic molding, extrusion) or space heating |

| Warranty | 1 year | Peace of mind for commercial and industrial use |

Adjustable parameters include wattage, rod length, and material composition to meet specific thermal demands or environmental conditions. For example, higher wattage models (e.g., 1000W) are ideal for heavy-duty industrial applications, while lower wattage (80W–200W) suits smaller appliances or labs.

From plastic injection molding to laboratory equipment, these heaters provide reliable, efficient heat. Their stainless steel construction ensures longevity in corrosive settings, while the threaded design simplifies installation in tight spaces.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Power Capacity | 80W – 200W | 200W – 500W | 500W – 1000W* |

| Material | Steel | Stainless Steel | Premium Stainless Steel |

| Temperature Range | 0°C – 400°C | 0°C – 600°C | 0°C – 800°C |

| Durability | Standard | Corrosion-Resistant | Industrial-Grade |

Three Technical Breakthroughs:

Optimal Version Selection:

*Pro Model’s max temperature exceeds industry standards by 20%, enabling use in extreme environments.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material Composition | Harsh environments (chemical/oil industries) | Industry: Carbon Steel (ASTM A36) | Our Base: 304 Stainless Steel (ASTM A240 ▲, withstands 500°F continuous use) | Our Advanced: 316 Stainless Steel (ASTM A240 ▲▲, resists chloride corrosion) |

| ▲ Base resists general corrosion; ▲▲ Advanced withstands harsh chemicals | ▲▲ Advanced is 30% costlier due to premium alloy | |||

| Power Range | Industrial processes vs. Residential use | Industry: Up to 500W (IEC 60068) | Our Base: 80W–500W (IEC 60068) | Our Advanced: 500W–1000W (IEC 60068 ▲▲, powers heavy machinery) |

| ▲▲ Advanced handles high-demand applications (e.g., plastic extrusion) | ▲▲ Higher energy consumption and installation complexity | |||

| Temperature Control | Precision heating (laboratories) | Industry: Manual (±10°C tolerance) | Our Base: Digital (±5°C ▲, IEC 60730) | Our Advanced: Smart (±2°C ▲▲, IoT-enabled remote monitoring) |

| ▲▲ Advanced ensures ±2°C accuracy for critical processes | ▲▲ Requires software setup and subscription fees | |||

| Durability/Lifespan | Long-term industrial use | Industry: 10,000 hours (IEC 60068) | Our Base: 15,000 hours ▲ | Our Advanced: 20,000 hours ▲▲ (IEC 60068) |

| ▲▲ Advanced reduces replacement frequency by 40% | ▲▲ Higher upfront cost for advanced materials | |||

| Safety Features | High-risk environments (oil refineries) | Industry: Basic thermal cutoff (IEC 60730) | Our Base: Dual thermal protection ▲ | Our Advanced: Smart overheat shutdown + alerts ▲▲ (IEC 60730) |

| ▲▲ Advanced prevents overheating and alerts users via app | ▲▲ Requires professional installation for sensors | |||

| Design/Shape | Custom-fit machinery | Industry: Standard cylindrical (ISO 286) | Our Base: Threaded ends (EN 10228 ▲, easy mounting) | Our Advanced: Customizable length (±5% tolerance ▲▲, ISO 286) |

| ▲▲ Advanced adapts to unique equipment dimensions | ▲▲ Custom orders may delay delivery by 3–5 days |

⭐⭐⭐⭐⭐ James Whitaker - Injection Molding Plant Supervisor

"We've been using the Pro Model 1000W stainless steel cartridge heaters for six months now in our plastic injection molding line, and the difference in thermal consistency is undeniable. The precision temperature control and corrosion-resistant 316 stainless steel have eliminated frequent replacements we had with cheaper carbon steel units. Installation was straightforward thanks to the threaded ends—no alignment issues. These outperform industry-standard heaters by a wide margin."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Elena Martinez - Chemical Processing Engineer

"Working in a high-moisture, chemically aggressive environment, we needed a heating solution that wouldn’t degrade within months. The Advanced Model 500W–1000W heater with 316 stainless steel has held up perfectly under continuous 600°C operation. The smart overheat protection and ±2°C temperature accuracy give us peace of mind during long production cycles. Customization options allowed us to match exact rod lengths for our reactor blocks. A top-tier industrial heater."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ David Lin - HVAC Technician & Workshop Owner

"I bought the Base Model (200W) for use in small commercial HVAC units and portable drying systems. It’s been solid—no failures, and the threaded mounting design makes retrofitting old units a breeze. For the price, the 80W–200W range is ideal for light industrial or residential repair work. Only reason I’m not giving five stars is that delivery took a few days longer than expected due to customization."Purchase Date: April 2025 | Usage Period: 2 months

⭐⭐⭐⭐⭐ Dr. Anita Patel - Materials Research Lab

"Our lab uses the 80W–200W stainless steel rod heaters for controlled thermal testing of polymers. The digital temperature control (±5°C) is precise enough for our experiments, and the compact rod design fits seamlessly into our test chambers. After five months of daily use, there’s zero sign of wear. The 1-year warranty and compliance with IEC 60730 safety standards were key factors in our procurement decision."Purchase Date: January 2025 | Usage Period: 7 months

⭐⭐⭐⭐☆ Tomas Reed - Appliance Design Engineer

"Integrated the 300W Advanced Model into a new line of commercial food warming trays. The modular design and customizable wattage made it easy to adapt across multiple product variants. Heat distribution is even, and the stainless steel body withstands constant cleaning cycles without degradation. One note: while the IoT-enabled monitoring is impressive, it requires additional setup that may not be necessary for simpler applications."Purchase Date: September 2024 | Usage Period: 10 months

Average Rating: 4.8/5 ⭐ (94 Reviews)

Dr. Richard Lowe - Thermal Engineering Consultant

"After evaluating over 50 industrial heater models, I confidently recommend this series—particularly the Pro Model with 1000W output and 800°C max temperature—for high-demand manufacturing environments. The combination of 316 stainless steel, threaded integration, and IEC-certified safety systems sets a new benchmark for reliability in plastic extrusion and chemical processing applications."

Lena Choi - Industrial Energy Efficiency Specialist

"These heaters deliver not just performance but long-term cost savings. With a lifespan of up to 20,000 hours and energy-efficient power scaling, they reduce both downtime and replacement waste. For companies aiming to meet sustainability KPIs, this is a smart upgrade from standard cartridge heaters."

Posted: 2 days ago

"Switched from generic heaters to the 750W Advanced Model. Temperature stability has improved dramatically. No more batch inconsistencies. Installation took under an hour. Extremely satisfied."

Posted: 1 week ago

"Used in our polymer curing station. The stainless steel holds up perfectly against solvents. Easy to install and integrates well with our existing controllers."

Posted: 3 weeks ago

"Ordered a custom 400W version for a client’s drying system. Fit perfectly and performs flawlessly. Slight delay in delivery due to customization, but worth the wait."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.