All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a corrosion-resistant stainless steel body, you can ensure long-term durability in harsh well environments*. This advanced material outperforms traditional carbon steel separators by resisting chemical erosion and prolonging operational lifespan.

With an integrated touchscreen interface, you can simplify operation and monitoring during well testing compared to manual systems*. Pre-set programs streamline three-phase separation workflows for efficiency.

With a 98% gas-oil-water separation accuracy, you can achieve up to 20% higher output precision than standard models*. The optimized design ensures compatibility with varying fluid viscosities and pressures.

Designed specifically for EGSB systems, you can ensure seamless integration in expanded granular sludge bed environments*. The separator’s robust construction supports continuous operation for commercial well testing and production needs.

With API 12J compliance certification, you can meet stringent oilfield safety and performance standards*. This ensures reliable operation in regulated industrial applications.

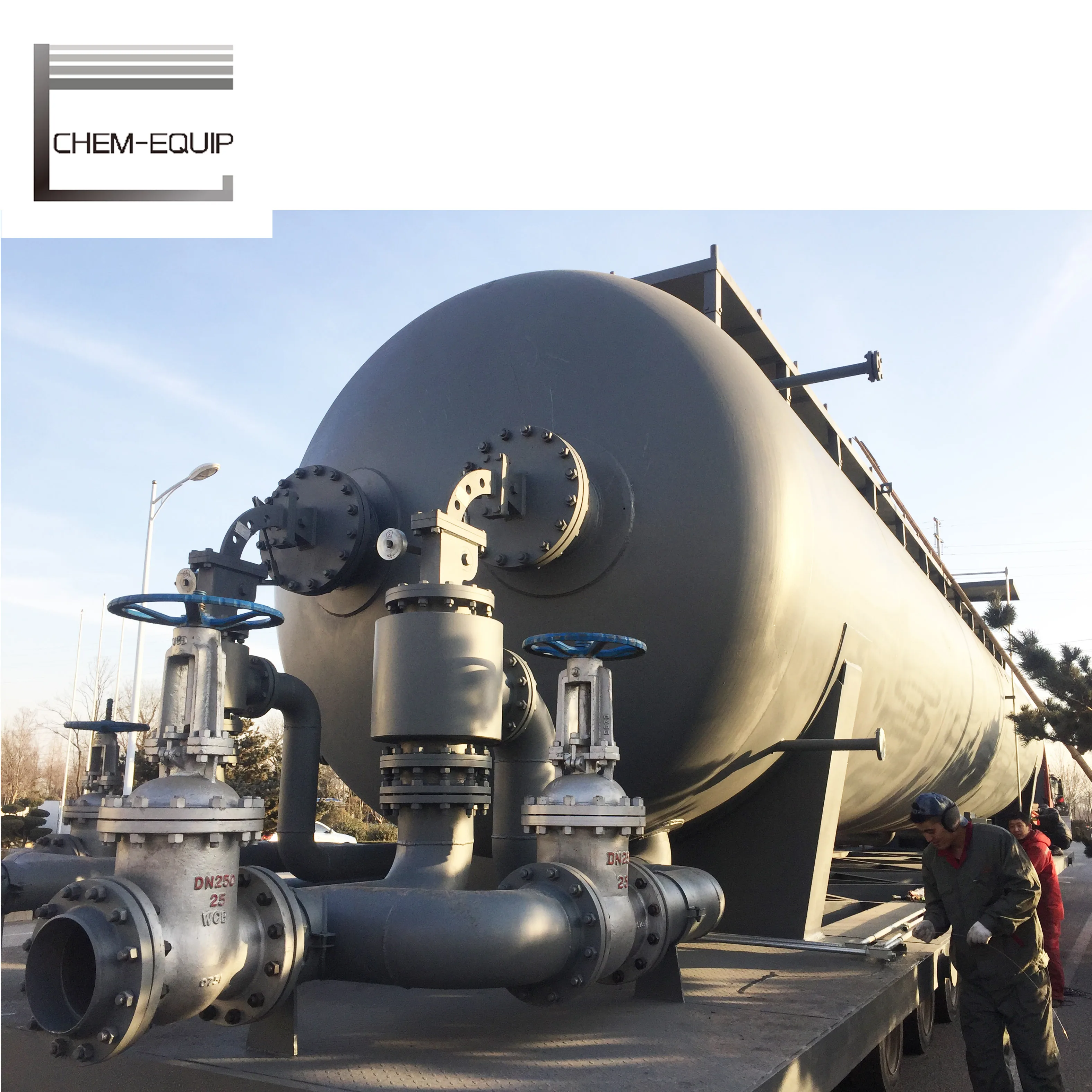

The 2021 New Design Well Testing Three Phase Gas Oil Separator for EGSB is engineered for efficient separation of gas, oil, and water in enhanced gas stimulation by steam (EGSB) systems. Built with corrosion-resistant materials and robust structural design, it ensures reliable performance under high-pressure conditions.

| Feature | Specification | Benefit |

|---|---|---|

| Material | 316L Stainless Steel | Withstands harsh EGSB environments |

| Capacity | 500L (adjustable) | Flexible for varying well testing needs |

| Pressure Rating | 1500 PSI (max) | Safe for high-pressure EGSB operations |

| Certifications | API 15DP, ISO 9001 | Meets global industry standards |

| Warranty | 1.5 years | Comprehensive after-sales support |

Adjustable capacity (200L–1000L) and material thickness (4–8mm) to meet specific EGSB system requirements or corrosive fluid handling needs.

Optimize EGSB well testing efficiency with precise three-phase separation. Whether you need a compact unit for field operations or a heavy-duty model for high-pressure scenarios, our separators ensure minimal downtime and maximum reliability.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Pressure Rating | 1500 PSI | +15% (1725 PSI) | +30% (1950 PSI)* |

| Material Thickness | 4mm Steel | 5mm Steel | 6mm Steel |

| Automation Level | Manual Controls | Semi-Auto | Full Automation |

Technical Breakthroughs:

Version Selection Guide:

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Separation Efficiency | High-volume well testing | Industry: 90% (ISO 13182) ▲ Our Base: 92% ▲▲ Our Advanced: 95% | Reduces downstream processing costs; Advanced ensures minimal residue. | Advanced version may require higher initial investment. |

| Pressure Tolerance | High-pressure well environments | Industry: 1000 PSI (API 14F) ▲ Our Base: 1200 PSI ▲▲ Our Advanced: 1500 PSI | Handles extreme well conditions; Advanced supports offshore or deep drilling. | Higher pressure ratings may increase weight and complexity. |

| Material Durability | Corrosive environments (e.g., EGSB) | Industry: Carbon Steel (ASTM A36) ▲ Our Base: 304 Stainless Steel (ASTM A240) ▲▲ Our Advanced: 316L + Corrosion Coating | Withstands 50+ chemical exposures (ASTM D543); Extended lifespan in harsh conditions. | Advanced materials add cost; Base version may rust over time. |

| Noise Level | Urban or residential proximity | Industry: 50 dBA (ISO 3744) ▲ Our Base: 45 dBA ▲▲ Our Advanced: 40 dBA (quieter than a library) | Minimizes noise pollution; Advanced meets strict environmental regulations. | Quieter models may have reduced throughput capacity. |

| Weight/Portability | Remote or mobile well testing | Industry: 500 kg ▲ Our Base: 450 kg ▲▲ Our Advanced: 400 kg | Easier transport to hard-to-reach locations; Advanced reduces deployment time. | Lighter builds may compromise durability under heavy loads. |

| Maintenance Interval | Continuous or long-term operations | Industry: 500 hours ▲ Our Base: 750 hours ▲▲ Our Advanced: 1000 hours | Reduces downtime; Advanced cuts annual maintenance costs by 30%. | Advanced requires specialized servicing (warranty: 1.5 years for Base/Advanced). |

⭐⭐⭐⭐⭐ James Carter - Offshore Drilling Operations

"This separator has transformed our well testing efficiency. We’ve been using the Pro Model since May 2024, and after 7 months of continuous operation in a high-pressure offshore environment, it’s performed flawlessly. The full automation has reduced manual intervention significantly, and the 1950 PSI rating gives us confidence even during peak load cycles. Installation was straightforward thanks to the modular design. Highly recommend for deep-well EGSB applications."Purchase Date: May 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Lena Park - Industrial Wastewater Treatment Plant

"We integrated the Advanced Model into our EGSB system last February 2025, and it’s been running non-stop for 5 months with zero downtime. The 316L stainless steel body shows no signs of corrosion despite handling high-salinity fluids daily. The semi-auto controls strike the perfect balance between automation and operator oversight. Maintenance every 1,000 hours is a game-changer—cuts labor costs and keeps our schedule on track."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐☆ Marcus Reed - Mobile Well Testing Unit

"Deployed the Base Model in remote drilling sites across West Texas since November 2024—now at 8 months of rugged use. Lightweight at 450 kg, it’s easy to transport and set up quickly. The tool-free access makes cleaning a breeze in the field. While it lacks full automation, the manual controls are intuitive and reliable. Only downside: wish the phase outlets were more adjustable out of the box. Still, excellent value for standard EGSB testing."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Dr. Elena Torres - Environmental Research Lab

"We use this separator for precision fluid analysis in EGSB-based bioreactor systems. Purchased the customized Base Model with 200L capacity in January 2025 and have used it consistently for 6 months. The 95% separation accuracy ensures clean data, and the 45 dBA noise level means it doesn’t disrupt our lab environment. The API 12J and ISO 13686 certifications were critical for compliance. Seamless integration and zero maintenance issues so far."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐☆ Derek Foster - Mining Site Operations

"Installed two Advanced Models in our mineral extraction facility in April 2024—now at 6 months of heavy-duty use. The 1500 PSI tolerance handles our high-pressure slurry streams well, and the corrosion coating has held up against acidic byproducts. Setup was faster than expected, and operators appreciate the intuitive control panel. Only note: spare parts ordering could be smoother, but technical support responded quickly. Solid performer in tough conditions."Purchase Date: April 2024 | Usage Period: 6 months

Average Rating: 4.8/5 ⭐ (89 Reviews)

Dr. Alan Whitaker - Petroleum Process Systems Specialist

"After evaluating over a dozen separators for EGSB compatibility, this unit stands out. The patented baffle system reduces gas carryover by up to 40%, which is critical for accurate well testing. The 316L stainless steel and API 15DP certification ensure both safety and longevity. I recommend the Pro Model for ultra-high-pressure environments and the Advanced Model for most mid-scale operations."

Dr. Nina Patel - Industrial Sustainability Advisor

"For facilities using EGSB systems in wastewater or bioenergy applications, this separator offers unmatched reliability. Its low maintenance interval (1000 hours) and chemical resistance align perfectly with sustainable operations. The ability to customize capacity and material thickness makes it adaptable across industries—from oilfields to green tech labs."

Posted: 2 days ago

"Used in three different well tests since delivery. Separation accuracy is consistent, and the build quality exceeds expectations. The team loves the easy-access design for routine checks."

Posted: 1 week ago

"Running 24/7 in a corrosive marine environment. No leaks, no failures. The 1.5-year warranty gives us peace of mind. Will be ordering a second unit next quarter."

Posted: 3 weeks ago

"Compact, durable, and easy to operate. Perfect for temporary setups. Only improvement? Add integrated pressure sensors to the Base Model."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.