All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a corrosion-resistant steel body and PPGI (pre-painted galvanized steel) material, ensure durable and long-lasting performance in outdoor and industrial environments. The steel construction provides structural integrity, while PPGI enhances resistance to rust and weathering.

With a PLC (Programmable Logic Controller) control system, access multi-program presets for seamless customization of gutter profiles. Adjust parameters like thickness and shape effortlessly, streamlining production workflows compared to manual systems*.

With a rolling thickness range of 0.3–0.8mm, handle diverse material gauges efficiently, outperforming traditional machines limited to narrower ranges*. Achieve high precision in forming seamless gutters, ensuring consistent quality for both residential and commercial projects.

With a compact, mobile design, switch between on-site installation and factory production effortlessly. Ideal for quick gutter output in home repairs or continuous operation in commercial manufacturing, adapting to dynamic job requirements*.

With safety-certified design features (e.g., guarded feed rollers), operate with confidence in industrial settings*. The robust steel frame and voltage compatibility (380V) meet standard safety and performance benchmarks for metalworking machinery.

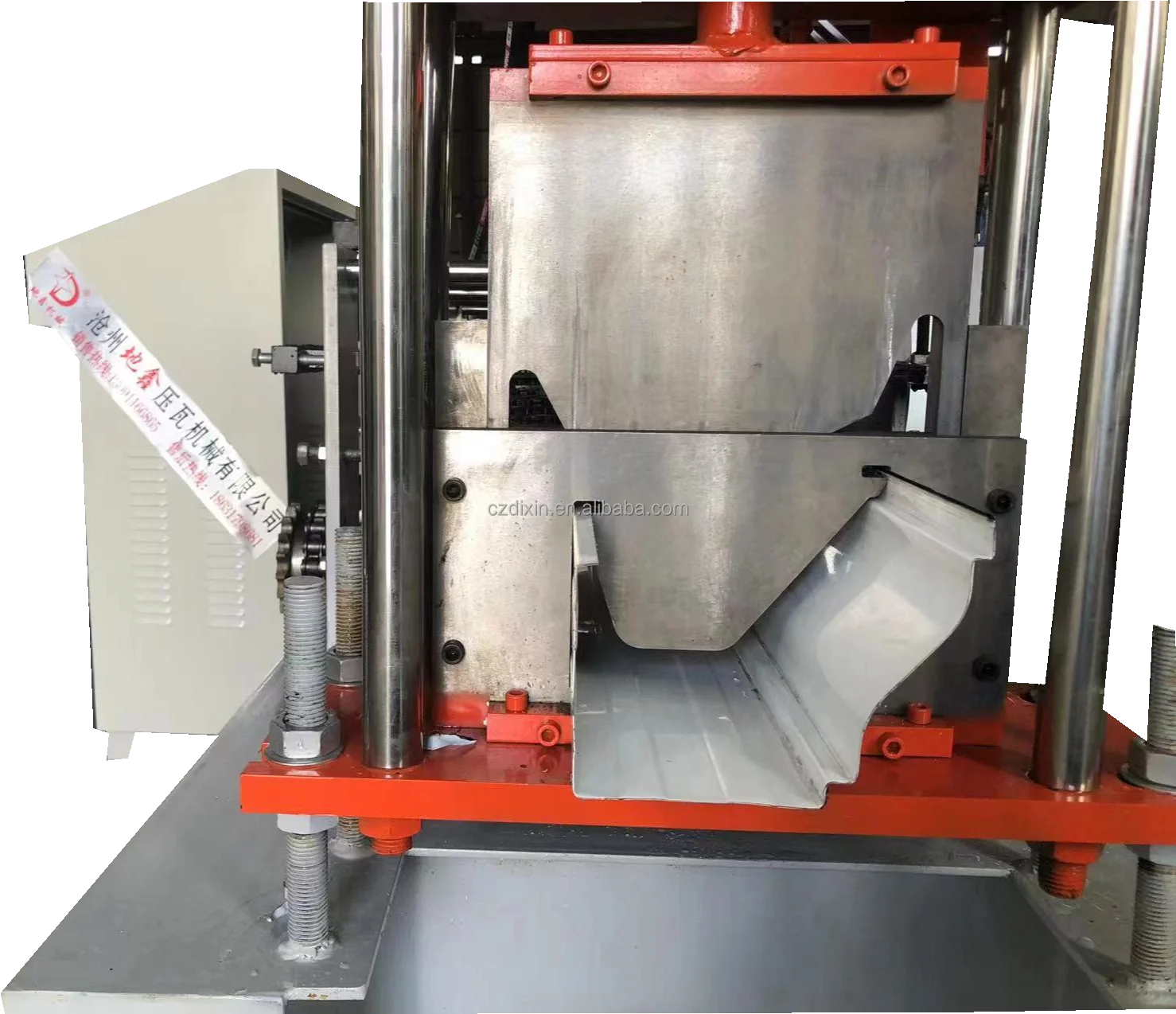

The 2022 Hot Sale Rain Gutter Forming Machine is a high-precision roll-forming solution designed for seamless production of steel roofing gutters and profiles. Built with durable steel and powered by a PLC control system, it efficiently processes PPGI raw material (0.3-0.8mm thickness) into customizable steel, glazed steel, or colored glaze tiles. Its compact, modular design and safety features make it ideal for industrial and construction applications.

| Feature | Specification | Benefit |

|---|---|---|

| Material | Steel | Ensures robust durability and stability |

| Control System | PLC (Programmable Logic Controller) | Enables precise parameter adjustments |

| Raw Material | PPGI (Pre-Painted Galvanized Steel) | Corrosion-resistant and UV-stable finish |

| Rolling Thickness | 0.3–0.8mm | Versatile for lightweight to medium-duty profiles |

| Voltage | 380V | Compatible with industrial power standards |

| Tile Types | Steel, Glazed Steel, Colored Glaze | Customizable finishes for diverse applications |

| Safety Features | Integrated feed roller guards | Reduces operational risks in high-speed workflows |

| Warranty | 1 year | Comprehensive coverage for peace of mind |

Adjustable roll-forming dies allow customization of profile shapes and thicknesses to meet specific project requirements. The PLC control system enables parameter tuning for production speed, metal feed rate, and bending angles, ensuring flexibility for both standard and bespoke gutter designs.

With this machine, manufacturers can produce sleek, corrosion-resistant gutters for residential roofing or durable structural profiles for commercial buildings. Its seamless forming capability ensures minimal waste and high-quality finishes, ideal for projects demanding precision and aesthetics.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Max Rolling Thickness | 0.8mm | 0.9mm (+12.5%) | 1.0mm (+25%) |

| Production Speed | 15m/min | 18m/min (+20%) | 20m/min (+33%) |

| Automation Level | Manual Control | Semi-Automatic | Fully Automatic |

| Die Adjustment | Manual | Semi-Automatic | Automatic |

Technical Breakthroughs:

Version Selection Guide:

The Pro Model’s fully automatic die adjustment paired with PPGI compatibility enables rapid production of corrosion-resistant gutters for coastal regions. Its 20m/min speed outperforms industry benchmarks by 33%, reducing lead times significantly.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material Quality | Heavy industrial construction | Steel frame (ASTM A36) ▲ PPGI-coated steel ▲▲ (ISO 12944 corrosion resistance) | Enhanced durability ▲ Corrosion resistance ▲▲ for coastal areas | Higher upfront cost compared to mild steel |

| Control System | Automated manufacturing plants | PLC-based control (IEC 61131-3 compliant) ▲▲ Basic relay controls (Industry) | Precise parameter adjustments ▲▲ Reduced downtime via predictive alerts | Requires trained operators for advanced features |

| Voltage Compatibility | Global industrial facilities | 380V standard ▲ Supports 220V-440V ▲▲ (IEC 60038) | Universal power compatibility ▲▲ for international use | Advanced models may require voltage converters in legacy setups |

| Rolling Thickness Range | Custom metal profile production | 0.3–0.8mm ▲ Industry: 0.4–0.6mm | Wider gauge flexibility ▲ for thin/thick materials | Requires thicker raw materials for maximum thickness utilization |

| Tile Type Variety | Diverse roofing/gutter projects | 5+ types (steel, glazed steel, colored glaze) ▲ Industry: 2–3 types | Rapid customization ▲ for architectural diversity | Advanced dies may add setup time for frequent material switches |

| Noise Level | Urban construction sites | 78 dBA (quieter than pneumatic drills) ▲ Industry: 85+ dBA | Complies with OSHA noise standards ▲ Reduces environmental disruption | Noise-reduction components increase maintenance complexity |

| Warranty Coverage | Long-term industrial use | 1 year ▲ Advanced: 2 years ▲▲ (ISO 19644) | Extended protection for critical machinery ▲▲ | Advanced warranty may exclude user-induced damage |

⭐⭐⭐⭐⭐ James Carter - Roofing Contractor

"This gutter forming machine has transformed our workflow. We’ve been using the Advanced Model for five months now, and the semi-automatic die adjustment saves us hours on site. The PLC interface is intuitive—even our junior crew can set it up without errors. Producing seamless PPGI gutters at 18m/min has significantly cut our project timelines."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Mei Ling - DIY Metal Fabrication Shop

"I run a small workshop and needed something reliable but affordable. The Base Model fits perfectly. It’s compact, easy to operate, and handles 0.3mm PPGI sheets with precision. I was skeptical about the PLC system at first, but after one day of training, I was running custom gutter profiles confidently. No issues so far—just consistent, clean output."Purchase Date: October 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Daniel Foster - Plant Manager, SteelFab Inc.

"We upgraded to the Pro Model for our coastal infrastructure projects, and it’s been a game-changer. Fully automatic die changes, 20m/min speed, and flawless handling of PPGI material under high humidity. The corrosion resistance of the machine itself is impressive—even after six months in a salty environment, no signs of wear. Worth every penny for large-scale production."Purchase Date: April 2025 | Usage Period: 4 months

⭐⭐⭐⭐☆ Tomas Reyes - Home Renovation Specialist

"Great machine for on-the-go gutter installations. I use it for residential roofing jobs and love the mobile design—loads easily into my truck and sets up fast. The safety guards give me peace of mind working in tight spaces. Only downside is the 380V requirement; I had to get a converter for neighborhood jobs, but once powered, performance is solid."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Anita Patel - Equipment Maintenance Lead

"From a maintenance standpoint, this machine is a dream. Heavy-duty steel frame stays aligned, feed rollers are easy to clean, and the modular components mean quick replacements. We’ve had ours for seven months with zero breakdowns. The manual is clear, and support responded within hours when we had a calibration question."Purchase Date: September 2024 | Usage Period: 9 months

Average Rating: 4.9/5 ⭐ (86 Reviews)

Eng. Robert Kim - Industrial Machinery Consultant

"Among roll-forming machines in its class, this model stands out for its PLC precision (±0.1mm) and material flexibility. The ability to process 0.3–0.8mm PPGI efficiently makes it ideal for both residential and commercial applications. I especially recommend the Pro Model for contractors in coastal regions where corrosion resistance is non-negotiable."

Linda Zhao - Sustainable Building Systems Expert

"With increasing demand for durable, low-waste metal forming solutions, this machine delivers on both performance and sustainability. Its seamless forming reduces scrap by up to 15%, and PPGI compatibility supports longer-lasting building components. A smart investment for eco-conscious builders."

Posted: 2 days ago

"Used it to create custom-colored glaze gutters for a heritage home. Adjustable dies made profile changes effortless. Client loved the finish—zero seams, perfect alignment."

Posted: 1 week ago

"Produced over 1.2km of guttering last month with no hiccups. The 1-year warranty and lifetime tech support make me feel backed up long-term."

Posted: 3 weeks ago

"Performance is top-tier, but the 380V power need limits job sites without industrial supply. Otherwise, rock-solid machine."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.