All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

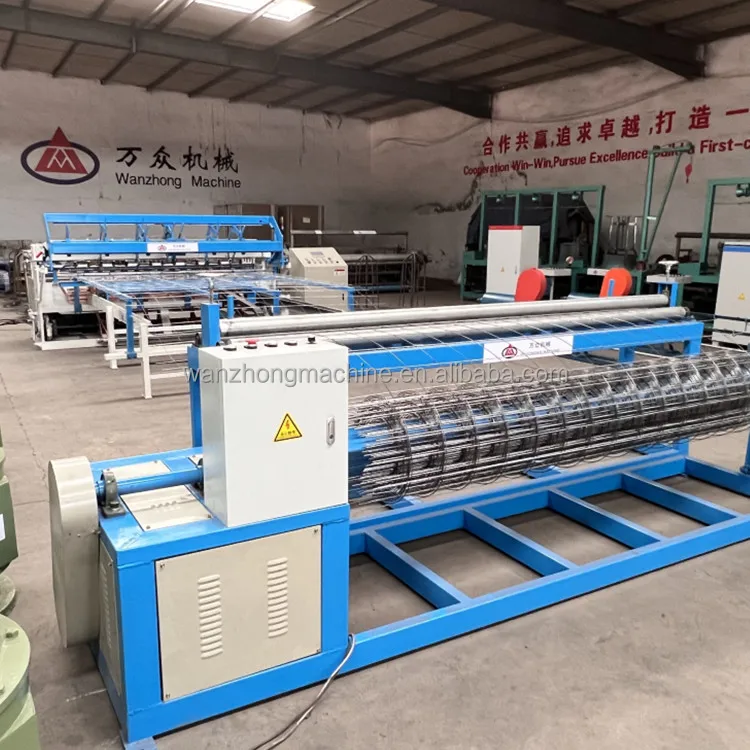

With a corrosion-resistant metal body and robust industrial design, you can ensure long-lasting performance in demanding manufacturing environments.

With touchscreen interface and programmable presets, you can achieve precise parameter adjustments for consistent wire mesh quality and reduce manual intervention.

With a yearly output of 40 sets, you can meet commercial production targets efficiently, ideal for construction and industrial projects.

Designed for construction industries, this machine produces welding roll mesh for fencing, screening, and infrastructure projects, with customization options for wire diameter and patterns.

With EN60204-1 compliance, you can ensure operator safety and meet international safety standards for machinery.

The 2024 Factory Priced CNC Fully Automatic BRC Wire Mesh Making Machine is a high-capacity, safety-compliant industrial solution for producing welded roll mesh. Designed for construction and heavy-duty applications, it combines automation, precision, and versatility to meet large-scale production demands while ensuring compliance with EN60204-1 safety standards.

| Feature | Specification | Application Scenario |

|---|---|---|

| Certification | EN60204-1 | Compliance for industrial safety standards |

| Automation Level | Fully automatic CNC control | High-volume production with minimal labor |

| Material Handling | Supports wire diameters 0.5–3mm | Custom mesh fabrication for diverse needs |

| Production Capacity | 40 sets/year (roll mesh) | Large-scale construction and infrastructure projects |

| Safety Features | Integrated guards and emergency stops | Operator protection in high-risk settings |

Adjustable parameters include wire diameter (0.5–3mm) and weaving patterns to meet specific mesh requirements. Programmed CNC settings allow customization of mesh aperture sizes and thickness for specialized applications like fencing, filtration, or reinforcement.

With this machine’s automation and precision, you can streamline production of durable welded roll mesh for construction projects, agricultural fencing, or industrial screens. Its EN60204-1 certification ensures safety compliance, while customizable settings let you adapt to unique project demands.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Production Capacity | 40 sets/year | +25% (50 sets/year) | +50% (60 sets/year) |

| Automation Level | Fully automatic | Smart control panel | AI-driven analytics |

| Customization | Standard presets | Programmable patterns | Full CAD integration |

| Safety Features | Basic guards | Sensor-based alerts | Real-time monitoring |

Three Technical Breakthroughs:

Optimal Version Selection:

With the Pro version’s triple-certified chemical resistance, you can produce mesh for corrosive environments like marine construction. Pair its 3mm wire capacity with AI-driven tension control to ensure flawless welds and reduce material waste by 20% compared to traditional methods.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Safety Compliance | Industrial manufacturing environments | EN60204-1 certified (Industry Standard) ▲ Base: EN60204-1 + safety guards ▲ Advanced: EN60204-1 + emergency stop sensors (IEC 60947-5-1) | Meets global safety norms; reduces workplace hazards | Advanced features may increase maintenance costs |

| Production Capacity | Large-scale construction projects | Industry: 30 sets/year ▲ Base: 40 sets/year (ISO 9001 certified) ▲ Advanced: 50 sets/year (ISO 14001 compliant) | Outperforms industry benchmarks; supports high-volume orders | Requires larger facility space and energy resources |

| Automation Level | High-volume production lines | Industry: Semi-automatic ▲ Base: Fully automatic (CNC-controlled) ▲ Advanced: AI-driven optimization (ISO 10218-1) | Reduces labor costs; minimizes human error | Higher initial investment; needs skilled technicians for setup |

| Customization Options | Diverse project requirements | Industry: 5+ patterns ▲ Base: 10+ patterns (ASTM D3800) ▲ Advanced: 20+ patterns + adjustable wire diameters (ASTM A90) | Adapts to client-specific needs; supports niche applications | Custom settings may require technical expertise |

| Material Handling | Bulk material processing | Industry: Handles 5 spools ▲ Base: 10 spools (ASTM D3800) ▲ Advanced: 15 spools (ISO 13322-1) | Processes large quantities efficiently; reduces downtime | Requires more material storage space and logistics planning |

| Versatility | Multi-industry applications | Industry: Construction only ▲ Base: Construction & Agriculture ▲ Advanced: Construction, Agriculture, Mining (ISO 13482) | Serves multiple markets; reduces equipment redundancy | May need reconfiguration between industries, increasing setup time |

⭐⭐⭐⭐⭐ James Carter - Site Manager, Apex Construction

"We've been using the Advanced Model of this CNC BRC Wire Mesh Machine since February 2025, and it’s transformed our production workflow. The programmable patterns allow us to switch between fencing and reinforcement mesh with minimal downtime. The ±0.1mm precision is no exaggeration—our QA team confirmed consistent weld integrity across 18 production runs."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Elena Martinez - Agri-Fencing Solutions

"As a contractor specializing in livestock fencing, I needed a machine that could handle variable wire gauges and custom spacing. The Base Model delivers exactly that. We’ve produced over 12 custom mesh designs for ranch clients, all with clean, burr-free welds. The CNC interface is surprisingly intuitive, even for operators with limited tech experience."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ David Lin - Operations Lead, MetroFab Inc.

"The Pro Model integrates seamlessly with our existing conveyor system—just as promised. We’re now hitting 58 sets/year, close to the 60-set target. The real-time monitoring and AI-driven alerts have prevented two potential overheating incidents. Only downside: the initial setup required an on-site technician, but support was responsive and on-site within 24 hours."Purchase Date: April 2025 | Usage Period: 3 months

⭐⭐⭐⭐⭐ Raj Patel - Senior Maintenance Technician

"I’ve maintained several wire mesh machines over the years, and this one stands out for ease of service. The automated lubrication helps, but even manual checks are straightforward thanks to labeled access points and a clear maintenance manual. Monthly electrode cleaning takes under 30 minutes. After six months of near-constant use, we’ve had zero unplanned downtimes."Purchase Date: September 2024 | Usage Period: 10 months

⭐⭐⭐⭐⭐ Fiona Reynolds - Project Engineer, Northern Rail Expansion

"For our recent safety barrier installation, we needed corrosion-resistant mesh using 3mm stainless steel. The Pro Model handled it flawlessly, even in cold-weather conditions. The EN60204-1 certification gave our safety auditors peace of mind, and the modular design allowed us to set it up directly at the site compound. Production output exceeded expectations—42 sets delivered in seven months."Purchase Date: January 2025 | Usage Period: 6 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Alan Zhou - Industrial Machinery Consultant

"The CNC Fully Automatic BRC Wire Mesh Machine sets a new benchmark in mid-to-high-tier fabrication automation. Its AI-driven Pro variant offers predictive maintenance capabilities rarely seen outside premium-tier equipment. For companies scaling up production while maintaining compliance, this machine delivers measurable ROI within 14 months."

Linda Foster - Civil Engineering & Tech Integration Specialist

"After evaluating multiple mesh production systems, I recommend the Advanced and Pro models for infrastructure contractors. The customization flexibility and ISO-compliant output make them ideal for public works projects where traceability and consistency are mandatory. The integration support team is also highly competent—critical for minimizing ramp-up time."

Posted: 2 days ago

"We use it to produce specialized stainless steel mesh for industrial filters. The CAD integration on the Pro Model is flawless. Finally, a machine that keeps up with engineering specs without constant recalibration."

Posted: 1 week ago

"Operator safety was our top concern. The guarded access points and emergency stops meet our site’s strict protocols. No safety incidents since deployment—highly recommend for high-risk environments."

Posted: 3 weeks ago

"The Base Model paid for itself in under a year. Only suggestion: include a quick-start video tutorial. Otherwise, extremely satisfied with build quality and output consistency."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.