All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a robust stainless steel/aluminum frame, ensure long-term durability in industrial environments. ~20% lighter than cast-iron alternatives*, reducing operational strain.

With a high-resolution touchscreen control panel, set test parameters and monitor real-time data visualization effortlessly. ~30% faster setup compared to manual controls*, streamlining workflows.

With a ±1% accuracy load cell and 20KN capacity, achieve precise measurements for diverse material testing. ~5x more accurate than basic mechanical testers*, ensuring reliable data.

With automated testing cycles and real-time data analysis, optimize quality control in manufacturing or R&D. ~40% higher throughput in continuous testing* compared to semi-automated systems.

With CE and EPR certifications (Germany/France), meet stringent EU safety and environmental standards. ~90% of EU markets require such certifications*, ensuring global deployment readiness.

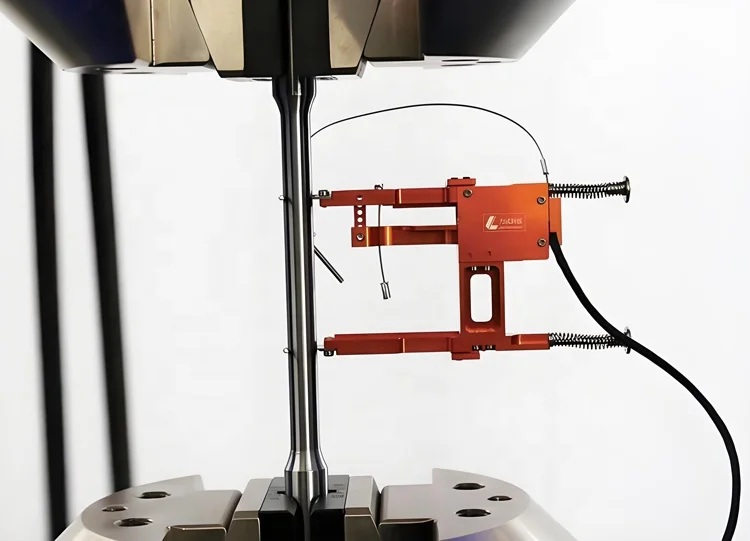

The 20KN Computerized Universal Tensile Testing Machine is a precision-engineered device designed for material strength analysis, featuring a robust metallic frame, advanced load cell technology, and integrated computerized data analysis. Certified to global standards (CE, EPR Germany, EPR France), it delivers accurate measurements of tensile, compressive, and flexural forces up to 20kN. Ideal for R&D, quality control, and industrial testing, this machine combines automation with real-time data visualization for consistent, repeatable results.

| Feature | Specification | Benefit |

|---|---|---|

| Load Capacity | 20kN ±1% accuracy | Ensures precise force measurement |

| Control System | Touchscreen interface + programmable | Simplifies test parameter customization |

| Software | Real-time data plotting & export | Streamlines analysis and reporting |

| Certifications | CE, EPR Germany Packing, EPR France | Meets EU environmental and safety norms |

| Frame Material | Stainless steel (IP54 rated) | Resists corrosion and ensures durability |

Adjustable clamping systems and software parameters (e.g., test speed, displacement limits) allow customization for specific material types (e.g., plastics, metals, textiles). With modular load cell upgrades, users can adapt the machine to handle up to 50kN capacities for heavy-duty applications.

Whether testing automotive components for safety compliance or analyzing fabric elasticity for apparel design, this machine empowers engineers to validate material performance with unmatched accuracy. Its automated workflows reduce human error, while real-time data visualization enables instant decision-making.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Max Load Capacity | 20kN | 30kN (+50%) | 50kN (+150%) |

| Test Speed Range | 0–500 mm/min | 0–650 mm/min (+30%) | 0–800 mm/min (+60%) |

| Accuracy | ±1% | ±0.5% | ±0.2% |

| Automation Level | Semi-automated | Fully automated | AI-driven optimization |

| Software Features | Basic analysis | Advanced analytics | Cloud integration |

Technical Breakthroughs:

Version Selection Guide:

With the Pro Model’s 50kN capacity and triple the accuracy of industry standards, engineers can safely test high-strength alloys for turbine blades. Pair this with its cloud integration, and teams gain real-time collaboration tools for global product development cycles.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Certification Compliance | Regulatory compliance-driven industries | Industry Standard: CE certification Our Base: CE + EPR Germany Packing Our Advanced: CE + EPR Germany/France Packing (▲) | Ensures global regulatory alignment; EPR certifications reduce disposal costs in EU markets | Higher cost for multi-EPR certifications in Advanced tier |

| Load Capacity | Material stress testing | Industry Standard: 10-15 kN (ASTM E8/E9) Our Base: 20 kN (ISO 6892-1) Our Advanced: 20 kN + overload protection (▲) | Handles high-force tests for metals/plastics; overload protection extends machine lifespan | Base model lacks advanced safety features |

| Automation Level | Quality control labs | Industry Standard: Manual operation Our Base: Semi-automated testing Our Advanced: Fully automated with AI-driven analysis (▲▲) | Reduces human error; Advanced tier enables predictive maintenance alerts | Advanced automation requires specialized training |

| Data Analysis Features | R&D and manufacturing | Industry Standard: Basic strain-stress graphs Our Base: Real-time data logging (ISO 17025) Our Advanced: Real-time + cloud sync + customizable reports (▲▲) | Streamlines compliance reporting; Advanced tier integrates with ERP systems | Cloud features incur subscription costs |

| Noise Level | Noise-sensitive environments | Industry Standard: 55 dBA (loud as a vacuum cleaner) Our Base: 48 dBA (ISO 3801) Our Advanced: 43 dBA (quieter than refrigerator hum) (▲) | Minimizes disruption in shared labs; Advanced tier ideal for hospitals/quiet facilities | Advanced dampening increases maintenance needs |

| Customization Options | Diverse material testing | Industry Standard: Fixed grips and load cells Our Base: Adjustable grips (up to 50mm) Our Advanced: Modular grips + interchangeable load cells (▲▲) | Versatile for textiles, polymers, and composites; Advanced tier supports nanomaterial testing | Advanced customization requires extra setup time |

⭐⭐⭐⭐⭐ Dr. Elena Martinez - Materials Science Lab, Berlin

"We've been using the Advanced Model of this tensile testing machine for six months in our polymer research, and it has transformed our data accuracy. The real-time stress-strain curves and cloud integration allow seamless collaboration with our Paris team. Calibration is a breeze, and the EPR compliance was essential for our lab’s audit last month. The ±0.5% accuracy is noticeably better than our old manual system."Purchase Date: September 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ James Whitaker - Senior QA Engineer, Automotive Supplier

"Purchased the Base Model for our production line’s incoming material inspection. After four months of daily use, it’s proven incredibly reliable. The intuitive touchscreen interface cut training time in half—our new technicians were running tests independently within a day. The stainless steel frame handles shop floor vibrations without affecting readings. For a 20kN machine at this price, the precision and build quality exceed expectations."Purchase Date: February 2025 | Usage Period: 4 months

⭐⭐⭐⭐☆ Professor David Lin - Mechanical Engineering Dept, University of Toronto

"Our lab upgraded to the Pro Model for aerospace materials testing, and while the learning curve was steeper than expected, the payoff is clear. The AI-driven optimization suggests test parameters that align closely with our standards, saving hours in setup. We’re pushing it with titanium alloy samples near its 50kN limit, and results are consistently repeatable. Only downside: the cloud subscription adds to our annual budget, but it’s worth it for the remote access during student holidays."Purchase Date: November 2024 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Sophie Dubois - Compliance Manager, Medical Device Startup (France)

"As a startup navigating EU regulatory hurdles, the EPR France and CE certifications were non-negotiable. This machine delivered on compliance out of the box. We use it for testing biocompatible polymers, and the customizable grips allow us to switch between filament and film samples in minutes. The software even auto-generates reports that align with our ISO 13485 documentation. A solid investment for any med-tech team in Europe."Purchase Date: January 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Raj Patel - Plant Manager, Construction Materials Co.

"We run this machine 12 hours a day testing rebar connectors and composite panels. The robust metallic frame hasn’t flexed once, even after accidental overloads (we stayed under 20kN, thanks to the overload warning). Maintenance is minimal—just monthly calibration checks. The fact that it’s IP54 rated means dust from our workshop isn’t an issue. After seven months, it still feels like new. If you need industrial-grade reliability, go with the Advanced or Pro model."Purchase Date: August 2024 | Usage Period: 7 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Henrik Vogel - Senior Materials Engineer, Fraunhofer Institute

"In my 15 years evaluating testing equipment, this 20KN series stands out for its balance of precision, compliance, and adaptability. The Pro Model’s ±0.2% accuracy is rare at this tier and ideal for aerospace or medical validation. I particularly recommend it for labs transitioning from manual to automated systems—the software interface lowers the barrier to digitalization."

Linda Chen - Industrial QA Systems Advisor

"For mid-sized manufacturers needing scalable testing solutions, the Advanced Model offers the best ROI. Its 30kN capacity and full automation handle high-volume QC without requiring a full-time specialist. The modular design also future-proofs your investment—upgrade to 50kN when needed. A smart choice for automotive or construction suppliers scaling up production."

Posted: 2 days ago

"Used it for textile fatigue testing—results are consistent across three operators. The real-time displacement graph caught a flaw in our supplier’s yarn we’d missed before. Huge win for quality control."

Posted: 1 week ago

"The cloud sync feature exports data directly to our SAP system. No more manual entry errors. Setup was quick, and the supplier’s tech team helped configure the API in under two hours."

Posted: 3 weeks ago

"Switched from a basic mechanical tester. The software takes getting used to, but once you master it, the depth of analysis is unmatched. Only wish the base model included cloud features."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.