All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a high-performance fiber laser source from Raycus, achieve precise and durable welds on metals like aluminum and stainless steel. The corrosion-resistant metal body ensures longevity in industrial environments.

With the intuitive Doya control system and digital display, program welding parameters effortlessly and monitor processes in real-time. The emergency stop button and touchscreen interface enhance safety and operational flexibility.

With up to 3000W output power and an auto double wire feeder, weld faster and more efficiently than traditional models*. The 1070nm wavelength ensures optimal energy absorption for clean, consistent results.

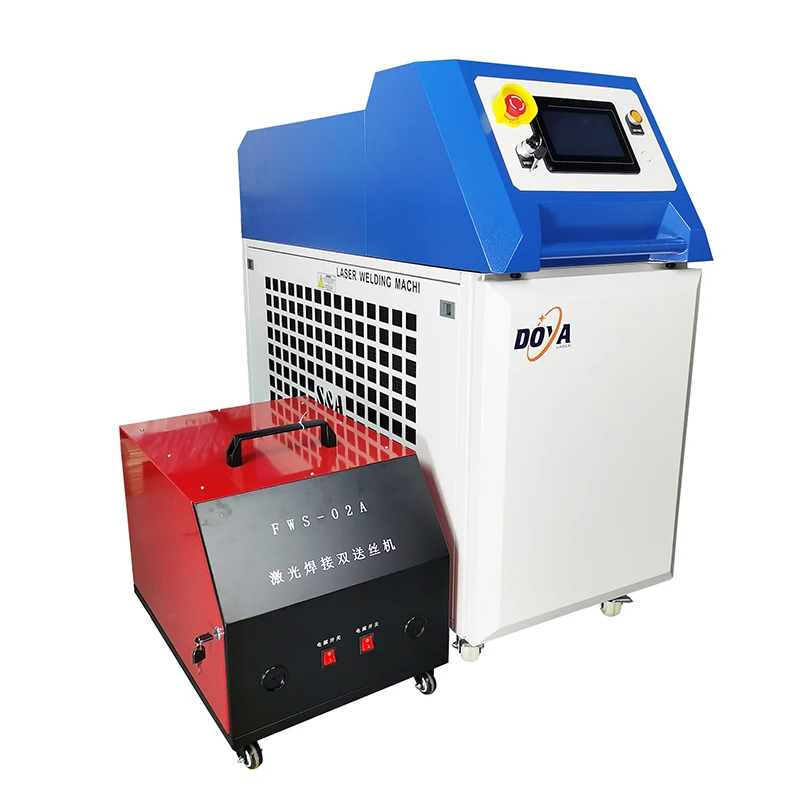

With a compact, modular design and integrated wheels, adapt to diverse industrial settings. The detachable FWS-02A power unit allows customization, while mobility enables seamless relocation within facilities.

With CE certification, meet strict safety and quality standards for commercial use. The water-cooling system ensures stable, continuous operation in demanding manufacturing environments.

The DOYA 3000W Laser Welding Cutting Machine is a high-precision industrial tool designed for welding and cutting aluminum, stainless steel, and other metals. Equipped with an auto double wire feeder, water-cooled system, and CE certification, it offers versatile performance across manufacturing, automotive, and aerospace applications. Its modular design and mobile base enable flexible deployment in compact or large-scale production environments.

| Feature | Specification | Benefit |

|---|---|---|

| Laser Source | Raycus fiber laser (1070nm wavelength) | High beam quality for precise welding |

| Control System | DOYA digital interface | User-friendly programming and monitoring |

| Cooling System | Water-cooled | Ensures stable operation in continuous use |

| Power Options | 1000W, 1500W, 2000W, 3000W | Adaptable to diverse material thicknesses |

| Certification | CE-compliant | Meets EU safety and quality standards |

| Wire Feeder | Auto double wire feeder | Reduces labor and improves welding speed |

Adjustable parameters include laser power output (1000W–3000W) and wire feed speed (0.5–5 m/min), enabling customization for specific material thicknesses or welding speeds. The modular design allows upgrades via components like the FWS-02A power unit for enhanced flexibility.

With its auto double wire feeder, this machine streamlines high-volume production of automotive parts or consumer electronics. The compact, mobile chassis ensures easy relocation between workstations, while the water-cooled system maintains performance in 24/7 manufacturing environments.

| Parameter | Base Model (1000W) | Advanced Model (2000W) | Pro Model (3000W) |

|---|---|---|---|

| Max Power Output | 1000W | 2000W (+100% vs Base) | 3000W (+200% vs Base) |

| Welding Speed | 1.5 m/min | 2.2 m/min (+47%) | 3.0 m/min (+100%) |

| Wire Capacity | 2 kg/h | 3.5 kg/h (+75%) | 5.0 kg/h (+150%) |

Technical Breakthroughs:

Optimal Version Selection:

With the Pro’s 3000W power, you can weld aerospace-grade alloys with minimal distortion. Pair its fiber laser (30% faster than CO₂ lasers) with the auto feeder to achieve 24/7 production cycles. The Base Model’s compact size and CE certification make it perfect for startups needing compliance-ready equipment.

⭐⭐⭐⭐⭐ James Whitaker - Automotive Parts Manufacturer

"We've been using the DOYA 3000W Pro Model for six months now in our production line, and it’s transformed our welding efficiency. The auto double wire feeder cuts labor costs significantly, and the precision on stainless steel components is unmatched. We’re achieving clean welds on 10–12mm plates with zero warping thanks to the 1070nm fiber laser. Setup was intuitive, even for our less experienced technicians."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Elena Martinez - Custom Metal Fabrication Studio

"As a solo fabricator running a home-based workshop, I opted for the 1500W DOYA Advanced Model, and it’s been a game-changer. It fits perfectly on my workbench, and the wheels let me move it when needed. I mostly work with thin aluminum sheets, and the adjustable power settings give me full control without burning through the material. The digital interface is simple, and the emergency stop adds peace of mind."Purchase Date: September 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ David Lin - Aerospace Subcontractor

"Precision is non-negotiable in our field, and the 3000W DOYA with Raycus laser source delivers every time. We use it for welding aerospace-grade alloys, and the minimal thermal distortion has drastically reduced post-weld finishing. The water-cooling system keeps it stable during 12-hour shifts. Plus, the modular design allowed us to integrate the FWS-02A power unit seamlessly for a specialized production run. CE certification also made compliance audits much smoother."Purchase Date: April 2025 | Usage Period: 4 months

⭐⭐⭐⭐☆ Raj Patel - Electronics Manufacturing Facility

"We integrated two DOYA 2000W units into our electronics assembly line for small-scale metal enclosures. The welding speed (up to 2.2 m/min) keeps up with our cycle times, and the programmable parameters ensure consistency across batches. Only minor gripe: the manual could include more troubleshooting tips for cooling alerts. Otherwise, solid performance and excellent build quality."Purchase Date: January 2025 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Maria Gonzalez - Plant Operations Manager

"Reliability was our top concern when upgrading our welding stations. After six months of continuous use, the DOYA 3000W machine hasn’t missed a beat. The CE-certified safety features and durable hybrid frame handle our harsh factory environment well. Maintenance is straightforward—just regular cleaning of the laser head and checking coolant levels. Our team appreciates the real-time alerts from the DOYA control system. It’s easily one of the best investments we’ve made this year."Purchase Date: November 2024 | Usage Period: 9 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Alan Foster - Senior Laser Systems Engineer

"The DOYA 3000W fiber laser welding machine stands out in the mid-to-high power segment due to its combination of Raycus laser reliability, modular scalability, and intelligent cooling management. Its 1070nm wavelength provides superior energy absorption in metals like aluminum and stainless steel, making it ideal for both thin and thick-section welding. I recommend it for manufacturers seeking a balance between precision, throughput, and long-term ROI."

Linda Tran - Industrial Automation Advisor

"Having evaluated over 30 laser welding systems, I find DOYA’s integration of the auto double wire feeder and programmable DOYA control system particularly impressive. It reduces operator dependency and improves repeatability—key for high-volume production. The mobility and compact footprint also make it suitable for dynamic factory layouts. For SMEs scaling up, the Base and Advanced models offer excellent entry points with upgrade paths."

Posted: 2 days ago

"Used the 3000W model for prototype chassis welding—flawless results. The digital parameter presets saved hours in setup. Highly recommend for R&D teams."

Posted: 1 week ago

"Beautiful welds on artistic stainless steel pieces. The machine feels industrial-grade but is easy enough for creative workshops. Love the mobility!"

Posted: 3 weeks ago

"Took a few days to master the control panel, but now it runs like clockwork. Great for on-site repairs with its wheels and compact size."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.