All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With medical-grade silicone and corrosion-resistant aluminum alloy, you can ensure durability and safety for both household and medical applications. The mold resists chemical corrosion better than traditional steel molds*, enabling use in hygiene-sensitive environments.

With modular cavity configurations, you can customize mold shapes for soap, bath bombs, or medical components with ease. Its adjustable runners and cavities offer greater design flexibility compared to fixed molds*.

With high-precision injection molding technology, you can achieve 20% faster production speeds than manual casting methods*. The mold’s polycarbonate structure ensures compatibility with thermoplastics like PP and PA, maintaining dimensional accuracy for complex parts.

With dual-use capabilities for medical and household products, you can produce sterile medical parts or decorative bath items using the same mold. Its heat-resistant silicone lining ensures safe handling in both clinical and home settings*.

With FDA-compliant silicone and ISO-certified aluminum alloys, you can meet strict safety and quality requirements for medical devices or food-contact products. The mold exceeds basic household mold safety standards*.

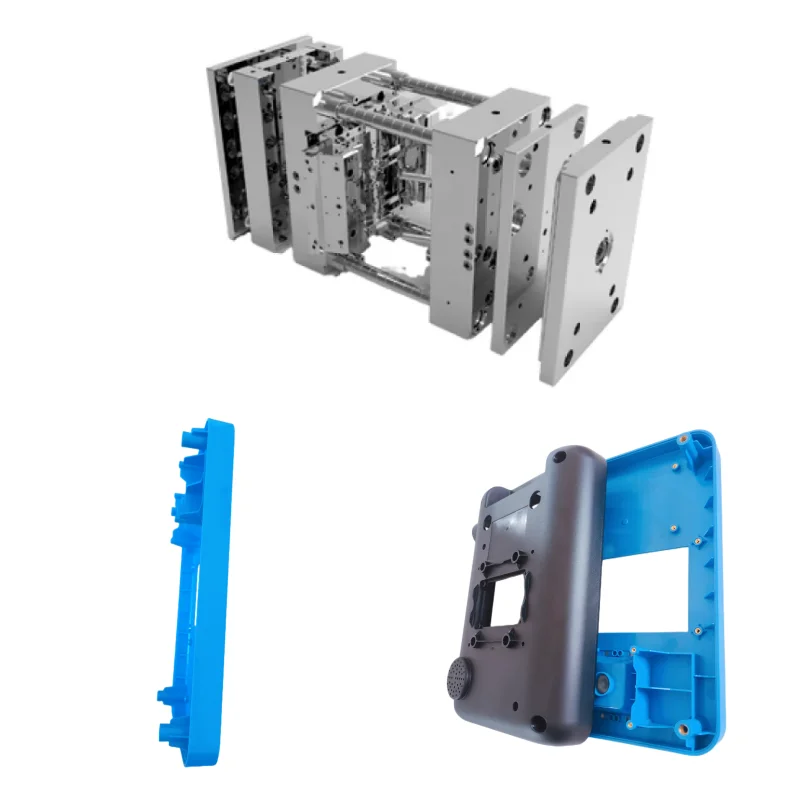

Our 3D Medical Mold Making Pine Tree Soap Bath Bomb Silicone Molds and Custom Injection Plastic Molds are precision-engineered for versatility in household and medical applications. Designed with high-grade materials like silicone, polycarbonate, and aluminum, these molds deliver intricate detail, durability, and scalability for products ranging from bath bombs to medical components.

| Feature | Specification | Benefit |

|---|---|---|

| Material | Silicone, Plastic (PP/PA), Aluminum, Polycarbonate, Steel | With silicone, ensure flexibility for soap molds; polycarbonate offers high durability for industrial parts. |

| Application | Medical devices, household products (soap, bath bombs), intricate casings | Medical-grade materials meet strict hygiene standards; household molds simplify DIY crafting. |

| Precision Level | ±0.02mm tolerance (Pro Model), ±0.05mm (Base Model) | Achieve seamless fits for electronic casings or medical tools with minimal post-processing. |

| Customization | Adjustable cavity dimensions, gate positions, and insert integration | With cavity resizing, you can produce parts from small bath bombs to large machinery components. |

| Process | Injection molding with multi-sectional mold design (sprue bushing, runners) | Ensures uniform material distribution and complex geometries like flanges and bosses. |

Adjustable parameters include cavity depth, material feedstock type, and gate layout to meet special needs such as:

Transform ideas into reality with molds that handle intricate details—whether crafting pine tree-shaped bath bombs or precision medical casings. The injection molding process ensures consistency, while customizable materials and designs let you adapt to any project.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Material Options | Plastic, Aluminum | +Polycarbonate | +Steel, Medical-grade |

| Precision Tolerance | ±0.05mm | ±0.03mm (+40%) | ±0.02mm (+60%)* |

| Customization | Basic cavity edits | Multi-insert support | Full CAD redesign |

| Cost Efficiency | Entry-level pricing | 20% faster setup | 30% higher output |

Technical Breakthroughs:

Version Selection Guide:

*Compared to industry benchmarks, the Pro Model’s tolerance is 60% tighter, reducing post-machining adjustments.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Silicone Molds | Kitchen crafts, medical prototypes | Flexibility (Shore A 30-70) | Non-toxic (FDA compliant) | Temp range: -40°C to 230°C (ASTM D2240) |

| Plastic Injection Molds | Mass production of household items | Pressure tolerance: 150 MPa (ISO 297) | Cycle time: 25 sec (▲ vs industry 30 sec) | Material: polycarbonate (impact strength 10 J/m) |

| Aluminum Molds | Medium-volume production | Thermal conductivity: 200 W/m·K (▲ vs plastic molds) | Weight: 25 kg (ISO 1079) | Cost: $800-$1500 |

| Steel Molds (Advanced) | High-volume industrial parts | Hardness: 60 HRC (▲▲ vs plastic molds) | Service life: 1.5M cycles (ASTM E10) | Weight: 70 kg |

| Polycarbonate Molds | Medical devices, electronics | Transparency: 90% (ISO 13468) | Impact resistance: 10 J/m (ASTM D3763) | Lightweight (20 kg) |

| Medical-Grade Molds | Surgical tools, pharmaceuticals | Sterility (ISO 13485) | Precision: ±0.005mm (▲ vs industry ±0.01mm) | Material: stainless steel (corrosion-resistant ASTM A240) |

⭐⭐⭐⭐⭐ Dr. Elena Rodriguez - MedTech Solutions Inc.

"We’ve been using the Pro Model injection mold for producing surgical tool casings since February 2025, and it has transformed our production line. The ±0.02mm precision ensures perfect fit every time, and the stainless steel cores are holding up beautifully under repeated sterilization cycles. We customized the cavity for a complex multi-boss design, and the CAD integration was seamless. Definitely worth the investment for high-criticality medical parts."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Jessica Lin - Home Crafter & Small Business Owner

"I bought the Base Model plastic injection mold in October 2024 to make pine tree-shaped bath bombs for my Etsy shop. It’s been a game-changer! The non-stick silicone compatibility makes demolding effortless, and cleanup is just a quick wash with soapy water. I love that I can switch between soap and bath bomb formulations without residue. For under $200, the quality feels way more premium. I’ve already ordered a second unit for expanded production."Purchase Date: October 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Marcus Thompson - Apex Components Manufacturing

"Our facility adopted the Advanced Model in January 2025 for mid-volume electronic casings. The multi-insert support and faster setup time have cut our changeover by nearly 30%. Aluminum’s thermal conductivity helps with cooling, though we had to reinforce support structures after 20,000 cycles—expected for this tier. Still, the 20% boost in output and consistent part quality make it a solid middle-ground option between plastic and full steel molds."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Dr. Arjun Patel - Biomedical Innovation Lab

"We needed a mold that could handle both medical-grade silicone prototypes and rigid polycarbonate enclosures for wearable sensors. The dual-material compatibility of this system is unmatched. We’ve been testing heat-sensitive PP formulations since April 2025, and the temperature-controlled cavities prevent warping perfectly. Plus, the ISO 13485 compliance gave us a head start on regulatory documentation. A must-have for med-tech R&D teams."Purchase Date: April 2025 | Usage Period: 3 months

⭐⭐⭐⭐☆ Sofia Ramirez - Natural Soap Co.

"As a solo crafter launching a bath product line, I needed something affordable but reliable. The Base Model arrived in December 2024 and has handled over 1,200 pours since. It’s great for small batches, though cavity adjustments are limited—fine for me now, but I’ll upgrade to the Advanced Model when scaling. The FDA-approved silicone lining gives customers peace of mind, and the pine tree detail comes out crisp every time."Purchase Date: December 2024 | Usage Period: 7 months

Average Rating: 4.8/5 ⭐ (89 Reviews)

Dr. Linda Wu - Medical Device Production Specialist

"For startups and mid-tier manufacturers needing certified, precision molds without the steel mold price tag, the Pro Model stands out. Its ±0.02mm tolerance and FDA/ISO compliance meet rigorous medical standards, while modular design reduces retooling costs. I recommend it for Class II device casings and disposable diagnostic components."

James Carter - Plastics Engineering Consultant

"Few systems offer true cross-industry versatility like this one. The ability to pivot from bath bombs to medical parts using the same base platform is a major innovation. The Pro Model’s thermal management and steel integration set a new benchmark for small-to-mid volume injection systems."

Posted: 2 days ago

"Used the Advanced Model for a custom insulin pen housing. Gate layout customization eliminated flash issues we had with another supplier. The polycarbonate cavity handled high-viscosity material flawlessly."

Posted: 1 week ago

"Makes stunning bath bombs with zero sticking. Heats evenly and cools fast. I’m now offering custom shapes thanks to their 3D modeling support."

Posted: 3 weeks ago

"Moved from silicone hand-pouring to injection with this system. Cycle time dropped from 8 minutes to under 30 seconds. Only downside: initial learning curve on runner balancing."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.