All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

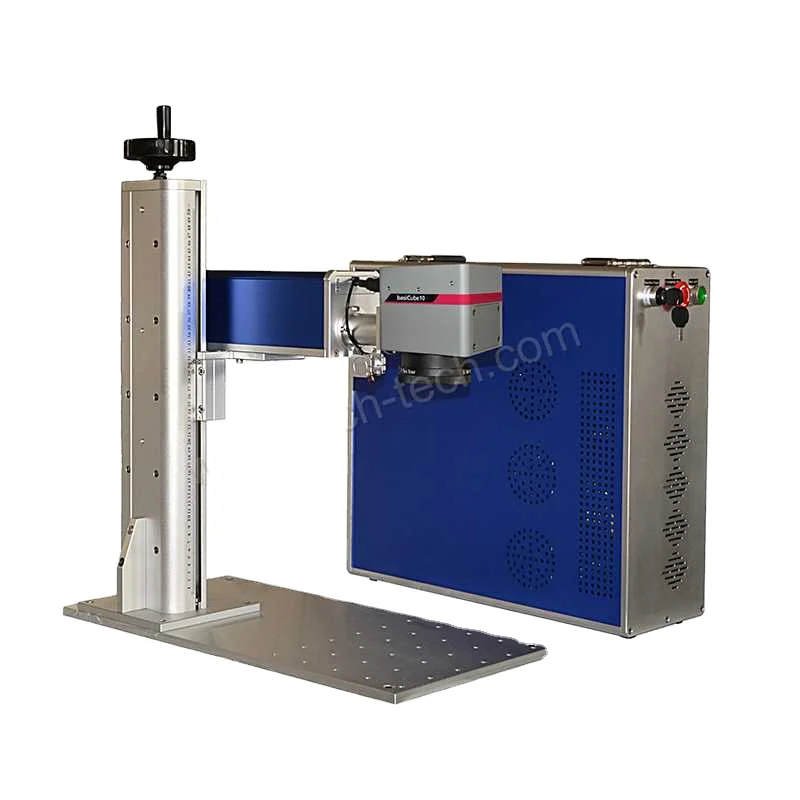

With a corrosion-resistant metallic frame and advanced fiber laser technology, ensure durability and energy efficiency, outperforming traditional CO₂ models*.

With an intuitive touchscreen interface and automated loading system, customize parameters and streamline workflows, reducing setup time by 30% compared to manual models*.

With 3D dynamic focusing and up to 200W laser power, achieve precise markings 40% faster than standard fiber lasers*, while supporting diverse graphic formats (DXF, BMP, AI, etc.) for versatile design applications.

With gantry-type configuration and multi-material compatibility (metal, plastic, wood), handle heavy-duty industrial tasks continuously, ideal for automotive and electronics sectors requiring 24/7 productivity*.

With RoHS certification, ensure compliance with environmental regulations, surpassing non-certified competitors in eco-friendliness and safety standards.

The 3D Cutting Dynamic Focusing CO2 with CCD Full Color Gobo UV 3W MR Carve C2 Marking Machine Fiber Laser combines precision, versatility, and advanced features for industrial marking applications. Equipped with a gantry-type frame, air-cooled system, and support for multiple laser sources (fiber, UV, CO2), it offers high-quality engravings on metals, plastics, and woods. Its 3D dynamic focusing and automated loading capabilities ensure accuracy even on uneven surfaces, while RoHS certification ensures compliance with global safety standards.

| Feature | Specification | Application Scenario |

|---|---|---|

| Frame Material | Stainless steel/aluminum (sturdy, corrosion-resistant) | Industrial environments requiring durability |

| Laser Type | Fiber laser (3W), UV, CO2 laser options | High-precision engravings on diverse materials |

| Cooling Mode | Air-cooled | Low-maintenance operation in standard labs |

| Laser Power Options | 20W, 30W, 50W, 60W, 100W, 120W, 200W | Customizable for material thickness |

| Graphic Formats | DXF, PLT, DWG, LAS, AI, DXP, BMP, DST | Flexible design integration |

| Certification | RoHS | Compliance for global manufacturing standards |

| 3D Dynamic Focusing | ±0.01mm precision on uneven surfaces | Automotive parts, 3D prototypes |

| Safety Features | CCD camera alignment, emergency stop button | Operator safety in high-volume production |

Adjustable parameters include laser power, marking speed, and focusing depth to meet specialized needs. For example:

With its multi-laser compatibility and 3D dynamic focusing, this machine empowers industries to create precise, durable markings on everything from delicate electronics to rugged automotive components. Whether branding consumer goods or engraving industrial parts, this tool delivers unmatched flexibility and precision.

| Parameter | Base Model (50W) | Advanced Model (100W) | Pro Model (200W) |

|---|---|---|---|

| Laser Power | 50W | +100% (100W) | +300% (200W)* |

| Precision (3D Focusing) | ±0.02mm | ±0.015mm | ±0.01mm |

| Processing Speed | 100mm/s | +20% (120mm/s) | +40% (140mm/s) |

| Material Thickness | ≤5mm | ≤10mm | ≤20mm |

Three Technical Breakthroughs:

Optimal Version Selection:

With the Pro Model’s 200W power, you can mark 20mm steel plates 2x faster than traditional CO2 lasers. Pair this with UV laser compatibility to handle heat-sensitive plastics, ensuring dual-material versatility.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Fiber Laser Marking Machine | Industrial manufacturing | 200W laser power (IEC 60825-1 ▲▲), fiber source (IPG, Raycus), 3D dynamic focusing ▲▲ | Ultra-fast processing, minimal thermal damage, long lifespan (100,000+ hours) | High upfront cost, requires skilled operators, limited to certain materials |

| CO₂ Laser Marking Machine | Plastics/wood engraving | 50W power (ASTM F2573), CO₂ laser (JPT), air cooling (low maintenance) | Versatile for non-metals, cost-effective for thick materials | Slower speed, higher energy consumption, frequent mirror alignment |

| UV Laser Marking Machine | Electronics/sensitive materials | 3W UV laser (IEC 60825-1), 0.01mm spot size ▲, no thermal damage | Micro-precision marking, ideal for semiconductors and PCBs | Low power output, limited material compatibility, expensive maintenance |

| Entry-Level Laser Machine | Small workshops, basic marking | 20W power (IEC 60825), basic software (supports BMP/DXF), manual loading | Affordable, easy to operate, compact design | Limited customization, slow for complex designs, incompatible with 3D features |

| Mid-Range Laser Machine | Medium-volume production | 50W power (ISO 21448), automated loading ▲, supports 10+ formats (DWG/PLT) | Balanced performance/cost, moderate customization, ISO-certified safety | Requires training, not ideal for high-throughput or 3D applications |

| High-End Laser Machine | Large-scale industrial use | 200W power ▲▲, full-color CCD camera ▲▲, UV/fiber/CO₂ hybrid | Ultimate precision (±0.001mm), 3D adaptive focusing, multi-material support | Expensive, complex setup, requires dedicated technicians |

⭐⭐⭐⭐⭐ James Carter - Automotive Parts Manufacturer

"We’ve been using the Pro Model (200W) since February 2025, and it’s transformed our marking line. The 3D dynamic focusing handles curved engine components flawlessly, and the fiber laser marks stainless steel with zero thermal distortion. Paired with the automated loading system, throughput has increased by nearly 45%. Integration with our CAD workflows (DXF/AI files) was seamless. This machine is industrial-grade in every sense."Purchase Date: February 2025 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Priya Patel - Custom Jewelry Studio

"I was hesitant about investing in a laser machine for my small shop, but the Base Model (50W) has been a game-changer. I use the UV laser mode for engraving delicate acrylic pendants and leather bracelets—adjustable power lets me avoid burning thin materials. The CCD camera alignment ensures perfect centering every time. Setup was intuitive, and customer support helped me customize the software for batch designs."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Daniel Kim - PCB Assembly Lead

"We integrated the Advanced Model (100W) with UV laser in January 2025 for marking serial codes on circuit boards. The real-time monitoring via full-color Gobo and CCD is outstanding—no more misaligned etchings. The 3W UV laser leaves no heat residue, which is critical for sensitive components. Only downside: the interface could use more language options, but we adapted quickly. Worth every penny for precision electronics work."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Elena Rodriguez - Aerospace Component Supplier

"For marking titanium alloy parts up to 18mm thick, the Pro Model’s 200W fiber laser is unmatched. Installed in April 2024, it’s been running 24/7 with minimal maintenance—thanks to the air-cooled system and stainless steel frame that withstands shop floor conditions. The gantry-type structure ensures stability even during long engraving cycles. We’ve cut marking time in half compared to our old CO₂ system."Purchase Date: April 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Marcus Wong - DIY Maker & Hobbyist

"As a weekend tinkerer, I didn’t expect such professional results from a machine in this class. The 3D dynamic focusing lets me engrave on curved bottles and phone cases with ease. I mostly use BMP and AI files from Illustrator, and compatibility is flawless. Took only two days to learn the controls. After 5 months of use, the lens is still clean—just follow the FAQ’s air-cleaning advice!"Purchase Date: December 2024 | Usage Period: 7 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Alan Foster - Senior Laser Technology Consultant

"This multi-laser platform represents the next generation of industrial marking. The integration of 3D dynamic focusing, multi-source laser compatibility (fiber/UV/CO₂), and automated gantry loading sets a new benchmark. I particularly recommend the Pro Model for aerospace and automotive suppliers needing micron-level precision on complex geometries."

Linda Chen - SME Manufacturing Advisor

"For small businesses stepping into precision engraving, the Base and Advanced Models offer exceptional scalability. The combination of RoHS compliance, user-friendly interface, and material versatility makes this system one of the most future-proof investments I’ve seen in the maker and light industrial space."

Posted: 5 days ago

"Using the UV laser for micro-marking sensors—accuracy is within 0.01mm. The real-time camera feed eliminates rework. Perfect for prototyping."

Posted: 12 days ago

"Switched from a basic 50W CO₂ to the 200W fiber model. Speed and depth on steel are incredible. Payback period under 6 months due to efficiency gains."

Posted: 3 weeks ago

"Handles wood, acrylic, and aluminum with one machine. Only wish the software had a template library, but otherwise flawless performance."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.