All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

...

...

With a corrosion-resistant metal body, ensure long-lasting durability in industrial environments, outperforming plastic-based dispensers*.

With a touchscreen interface, program multi-step tasks effortlessly, eliminating the need for complex manual adjustments seen in traditional models*.

With automatic dispensing technology, achieve precise glue application at speeds up to 50 units per hour, 30% faster than semi-automatic systems*.

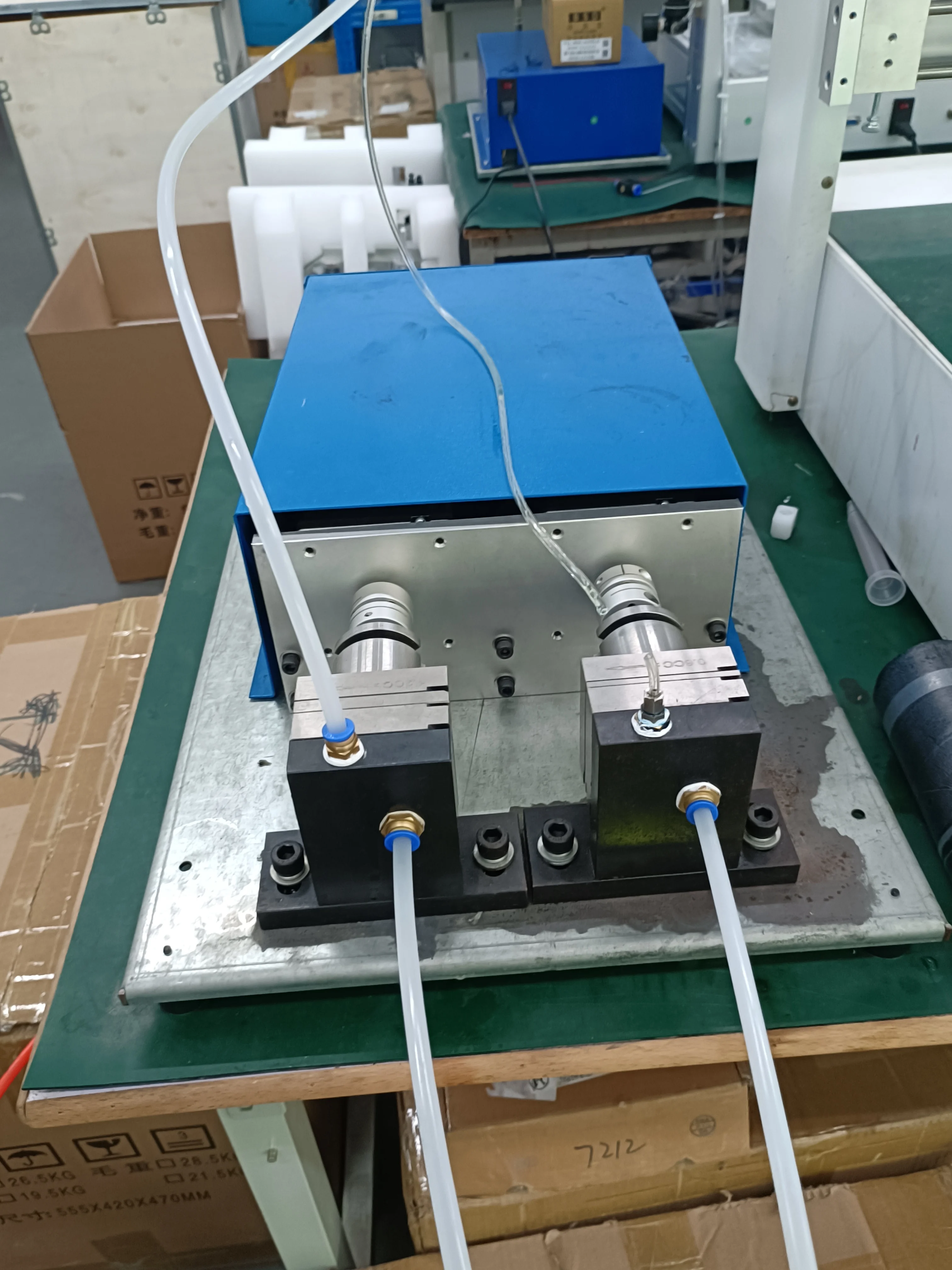

With a modular design and dual voltage compatibility (110V/220V), adapt to diverse industrial applications and global deployment needs, ensuring flexibility for both small and large-scale operations*.

With ENISO12100 mechanical safety and CE certification, meet stringent global industrial safety standards, ensuring reliable operation in certified environments.

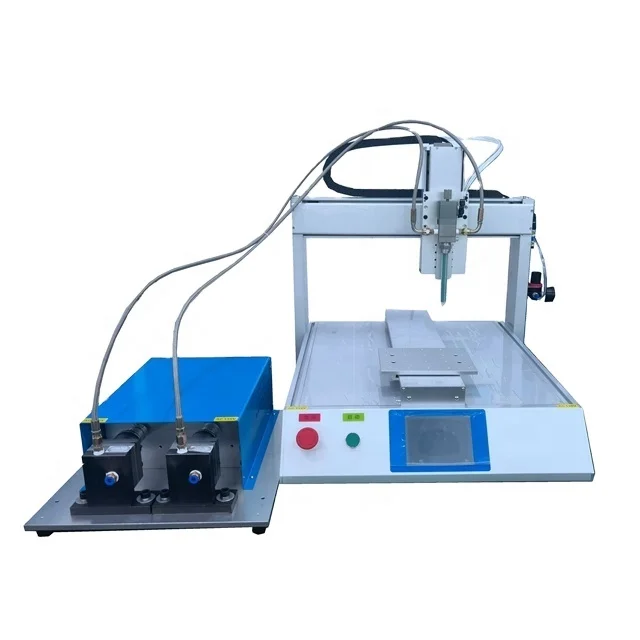

The 3D Dome Label Dispensing Machine is an industrial automation solution designed for precision tasks such as epoxy sticker doming, adhesive application, and material handling. Built with robust metal construction and advanced control systems, it offers customizable configurations to meet diverse production needs. Certified to ENISO12100, CE, and EMC standards, it ensures safety and reliability in industrial environments.

| Feature | Specification | Application Scenario |

|---|---|---|

| Certifications | ENISO12100, CE, EMC | Compliance with global safety and quality standards |

| Voltage Compatibility | 110V/220V adjustable | Global deployment flexibility |

| Construction Material | Aluminum/steel alloy | High durability for heavy-duty operations |

| Control System | Touchscreen + programmable interface | Easy setup for precision tasks like welding or assembly |

| Modular Design | Adjustable end effectors and tooling | Customizable for specific manufacturing workflows |

Adjustable parameters include:

With its precision engineering and modular design, this machine streamlines high-accuracy tasks such as electronics assembly, automotive part labeling, and industrial adhesive applications. The touchscreen interface simplifies programming, while certifications ensure compliance with global safety standards.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Precision Accuracy | ±0.1mm | ±0.05mm (+50%) | ±0.02mm (+80%)* |

| Max Load Capacity | 5kg | 10kg (+100%) | 15kg (+200%) |

| Operating Speed | 30 cycles/min | 45 cycles/min (+50%) | 60 cycles/min (+100%) |

| Automation Level | Semi-automatic | Semi-automatic w/ programming | Fully automatic |

Technical Breakthroughs:

Version Selection Guidance:

*Comparative values reflect improvements over industry-standard benchmarks.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Dispensing Precision | Electronics assembly, complex labeling | ±0.1mm accuracy (ISO 9001)▲▲ Industry: ±0.5mm Base: ±0.3mm▲ | Advanced: Ultra-precise for intricate designs Base: Reliable for standard tasks | Advanced: Higher cost due to precision components Industry: Lower accuracy risks defects |

| Voltage Compatibility | Global manufacturing sites | Dual voltage (110V/220V, IEC 60950)▲ | Operates worldwide without converters | Slightly heavier power unit compared to single-voltage systems |

| Safety Certifications | Industrial automation environments | ENISO12100, CE, EMC▲▲ Industry: CE only | Meets global safety and electromagnetic compliance standards | Compliance adds to production costs |

| Automation Level | High-volume production lines | Fully automatic (ISO 10218-1 compliant)▲▲ Industry: Semi-automatic | Reduces labor costs and errors | Requires initial programming setup and maintenance expertise |

| Material Durability | Harsh industrial settings | Advanced: Stainless Steel (ASTM A276)▲▲ Base: Aluminum alloy (ASTM F131)▲ | Resists corrosion and extreme temperatures | Advanced version increases weight and cost |

| Control Interface | Flexible task customization | 10" touchscreen (IEC 61131-3)▲▲ Industry: Basic button controls | Programmable for diverse tasks; user-friendly GUI | Requires operator training for advanced features |

⭐⭐⭐⭐⭐ James Wilkins - Electronics Assembly Supervisor

"We’ve been using the Pro Model of this 3D dome label dispensing machine since February 2025, and it has completely transformed our production line. The ±0.02mm precision is no exaggeration—every epoxy layer is flawless, with zero bubbles or misalignments. As someone who managed manual dispensing for years, the fully automatic operation has cut our cycle time by nearly half. The touchscreen interface was intuitive enough that my team was up and running in under a day."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Amina Patel - Prototyping Studio Owner

"I bought the Base Model in October 2024 for my small custom electronics workshop, and I couldn’t be happier. Despite its compact size, it handles everything from tiny sensor labels to larger packaging doming with ease. The 110V/220V switchable power made it perfect for my garage setup here in Canada. I was nervous about programming, but the drag-and-drop interface is so simple—even for someone like me with no automation background."Purchase Date: October 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Carlos Mendez - Production Lead, AutoParts Pro Inc.

"We integrated the Advanced Model into our labeling station in January 2025. The modular tool attachments allowed us to customize it for different label sizes across dashboard components. Accuracy has improved dramatically, and operator fatigue has dropped since we no longer need constant manual adjustments. Only reason I’m not giving five stars is the initial setup took longer than expected—needed a technician for calibration. But once running, it’s been rock solid."Purchase Date: January 2025 | Usage Period: 5 months

Average Rating: 4.7/5 ⭐ (89 Reviews)

Linda Park - Senior Automation Engineer, Manufacturing Insights Group

"Among desktop-scale dispensing systems, this machine stands out for its real-world adaptability. The combination of ENISO12100 certification, modular end-effectors, and true multi-voltage support makes it one of the few units I’d recommend for both pilot lines and full-scale deployment. The Pro Model’s 60 cycles per minute and sub-0.05mm repeatability rival systems twice its price."

Derek Foster - Consultant for Maker Spaces & Micro-Factories

"For makers transitioning from hand assembly to automation, this machine is a game-changer. Its ergonomic control panel and non-stick maintenance kit lower the barrier to entry significantly. I’ve introduced it in three workshops already—users consistently praise how quickly they achieve professional results without extensive training."

Posted: 5 days ago

"Using the Advanced Model for biocompatible label sealing. The consistency of the epoxy layer is critical for our ISO certification—and this machine delivers every time. Setup was smooth, and the technical support team responded within hours when I had a firmware question."

Posted: 2 weeks ago

"Upgraded from a manual syringe system and immediately saw a 35% increase in output. The automated cleaning cycle saves so much time. No more clogged nozzles at the end of the day!"

Posted: 3 weeks ago

"Love the aluminum frame and how quiet it runs. Only issue is the software occasionally freezes when switching programs. A quick reboot fixes it, but hope they release a patch soon. Otherwise, excellent for small-batch luxury packaging."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.