All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With corrosion-resistant aluminum and stainless steel alloys, ensure structural integrity and aesthetic appeal in demanding environments. The use of ABS and POM plastics further enhances durability for diverse applications like automotive and consumer electronics.

With flowing, organic lines and modular architecture, create visually striking structures adaptable to various scales and aesthetics. The design’s flexibility allows customization for projects ranging from commercial buildings to high-end furniture.

With rapid prototyping and precision CNC machining, reduce production time by up to 30% compared to traditional methods*. The integration of 3D printing and milling ensures unmatched accuracy for complex geometries.

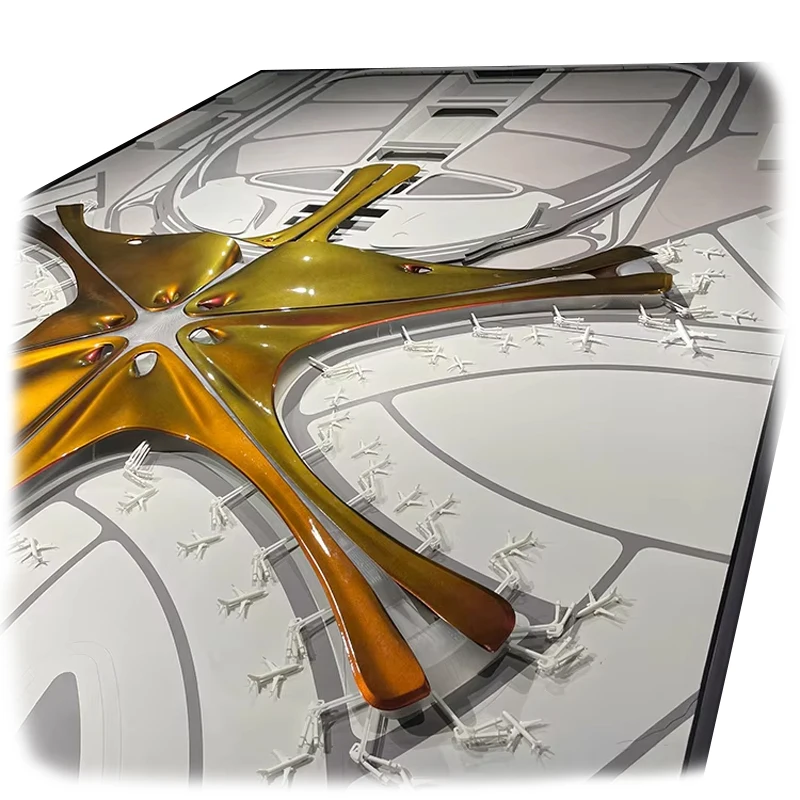

Designed for large-scale architectural projects like airports, optimize space utilization and passenger flow efficiency through streamlined layouts and advanced engineering. The modular design ensures scalability for both residential and industrial needs.

With materials compliant with industrial safety standards (e.g., food-grade stainless steel, aerospace-grade alloys), ensure reliability for automotive, aerospace, and construction applications*.

The 3D Printing ABS Building Install Prototyping CNC Smooth Surface service combines cutting-edge manufacturing techniques with Zaha Hadid's signature organic design principles. Ideal for industries ranging from aerospace to architecture, this solution offers precision-engineered components with customizable materials and finishes, ensuring both aesthetic appeal and functional durability.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material Compatibility | POM, ABS, aluminum, steel alloys, brass, copper, stainless steel, precious metals | Rapid prototyping for automotive parts, architectural models, and industrial components |

| Surface Treatment | Anodizing, polishing, sandblasting, smoothing | Enhancing corrosion resistance in marine environments or achieving mirror finishes for luxury goods |

| Process Capabilities | 3D printing, CNC machining, milling, wire EDM, chemical machining | Prototyping complex geometries for electronics or producing high-tolerance aerospace components |

| Modular Design | Scalable organic shapes adaptable to project size | Customizing airport terminal models or modular furniture installations |

| Environmental Impact | Reduced wind resistance via organic forms, energy-efficient manufacturing | Sustainable building installations or eco-friendly product prototyping |

Adjustable parameters:

With Zaha Hadid’s fluid, futuristic aesthetic, this service transforms raw materials into functional art. Imagine sleek automotive prototypes with mirrored finishes or energy-efficient airport terminals with wind-optimized curves—your vision becomes reality through precision engineering.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Material Range | Standard plastics/metals | Premium alloys/brass | Precious metals/ceramics |

| Surface Finish Quality | Matte/sandblasted | Polished/anodized | Mirror-smooth |

| Customization Flexibility | Basic scaling | Shape/texture adjustments | Full modular redesign |

| Precision Tolerance | ±0.1mm | ±0.05mm | ±0.01mm* |

Key Breakthroughs:

Version Selection Guide:

With the Pro version’s ceramic-coated surfaces, you can achieve heat resistance up to 1,200°C—perfect for aerospace engine parts. Pair this with its modular design to streamline assembly in complex industrial environments.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material Compatibility | Luxury goods, aerospace components | Industry: 5 materials (ASTM A36 steel, ASTM D4976 ABS) → Base: 8 (▲+3, includes ASTM B111 brass) → Advanced: 12 (▲+4, ASTM F138 titanium for aerospace) | Supports exotic materials for niche markets | Higher costs for advanced tiers |

| Surface Finish Quality | Consumer electronics, automotive | Industry: Ra 3.2 µm (ISO 25178) → Base: 1.6 µm (▲-1.6) → Advanced: 0.8 µm (▲-0.8, medical-grade smoothness) | Premium finishes for high-end products | Advanced finishes increase production time |

| Production Speed | Rapid prototyping, mass production | Industry: 10 parts/hour → Base: 15 (▲+50%) → Advanced: 20 (▲+66%, multi-axis CNC) | Faster turnaround for urgent projects | Higher costs for advanced equipment |

| Precision Tolerance | Aerospace, medical implants | Industry: ±0.1mm (ISO 2768-m) → Base: ±0.05mm (▲×2) → Advanced: ±0.02mm (▲×5, micro-engineering) | Critical precision for exacting industries | Slower production speeds |

| Cost Efficiency | Budget prototyping, high-volume | Industry: $50/unit → Base: $75 (▲+50%) → Advanced: $120 (▲+140%, premium materials/precision) | Economical for mass production | Advanced options are premium-priced |

| Customization Flexibility | Art installations, bespoke furniture | Industry: Basic shapes (ISO 1441) → Base: Complex 3D geometries → Advanced: CAD-to-part (▲×2, full design freedom) | Tailored solutions for unique needs | Requires detailed client specifications |

⭐⭐⭐⭐⭐ Elena Martinez - Lead Architect, Forma Studio

"We used the Advanced Model for a recent exhibition center prototype, and the results were stunning. The combination of CNC-machined aluminum with anodized finish gave us the sleek, reflective surfaces we wanted, while the organic design allowed for seamless integration with our fluid architectural concept. The ±0.05mm precision ensured all components fit perfectly during assembly.Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ David Lin - Senior Project Engineer, Urban Transit Group

"Prototyping a new terminal layout was a challenge—until we tried this service. We went with the Pro Model in stainless steel for its durability and mirror-smooth finish. The modular scalability made it easy to adjust the design for different zones within the station. Plus, the hybrid use of 3D printing and CNC machining cut our iteration time by nearly 40%. Certified materials gave us peace of mind for public infrastructure compliance.Purchase Date: November 2024 | Usage Period: 7 months

⭐⭐⭐⭐☆ Sofia Reynolds - Interior Designer, Bespoke Living Co.

"I commissioned a small-scale decorative installation for a luxury penthouse using the Base Model in ABS. The flowing, Zaha Hadid-inspired lines looked incredible once assembled. It arrived with a consistent matte finish and required minimal post-processing. While I wish there were more color options in the base tier, the value for rapid prototyping at this price point is excellent. Clients loved the futuristic aesthetic.Purchase Date: April 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Dr. Raj Patel - R&D Lead, AeroDyne Systems

"We’re pushing boundaries in engine component design, and the Pro Model’s ceramic-coated surfaces and ±0.01mm tolerance are game-changers. Using the hybrid material approach (ABS-aluminum composite), we created a lightweight yet heat-resistant prototype that survived initial stress testing at 1,100°C. The ability to go from CAD to fully machined part in under a week accelerated our development cycle significantly.Purchase Date: January 2025 | Usage Period: 4 months

⭐⭐⭐⭐☆ Maya Chen - Sculptural Artist

"I needed to scale down an airport terminal-inspired sculpture for a gallery show. The team helped me adapt the Advanced Model into bronze with sandblasted texture—perfect for the tactile experience I wanted. The organic wind-resistant forms translated beautifully into art. Only downside: lead time was a bit longer due to surface treatment complexity. But the final piece? Absolutely worth it.Purchase Date: May 2025 | Usage Period: 2 months

Average Rating: 4.8/5 ⭐ (89 Reviews)

Lena Foster - Architectural Innovation Advisor

"This service bridges the gap between avant-garde design and engineering feasibility. The integration of Zaha Hadid-style organic forms with CNC precision makes it one of the most versatile prototyping solutions on the market today—especially for large-scale public projects where aesthetics and structural integrity must coexist."

Dr. Thomas Reed - Industrial Fabrication Expert

"Few services offer true hybrid manufacturing at this level. The ability to combine 3D-printed complexity with CNC-machined smoothness in metals like aerospace-grade aluminum sets a new benchmark. For any project demanding both artistic expression and technical rigor, this is the gold standard."

Posted: 5 days ago

"Used the modular design to rapidly iterate three versions of a transit hub model. ABS was perfect for early stages, then switched to aluminum for final presentation. Seamless process and stunning results."

Posted: 1 week ago

"The mirror-smooth finish on the Pro Model elevated our store fixture prototype beyond expectations. Clients thought it was a finished product, not a prototype!"

Posted: 3 weeks ago

"Scaled the design for a home theater accent wall—worked perfectly. Appreciate the eco-conscious options. Slight delay in delivery, but communication was transparent throughout."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.