All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

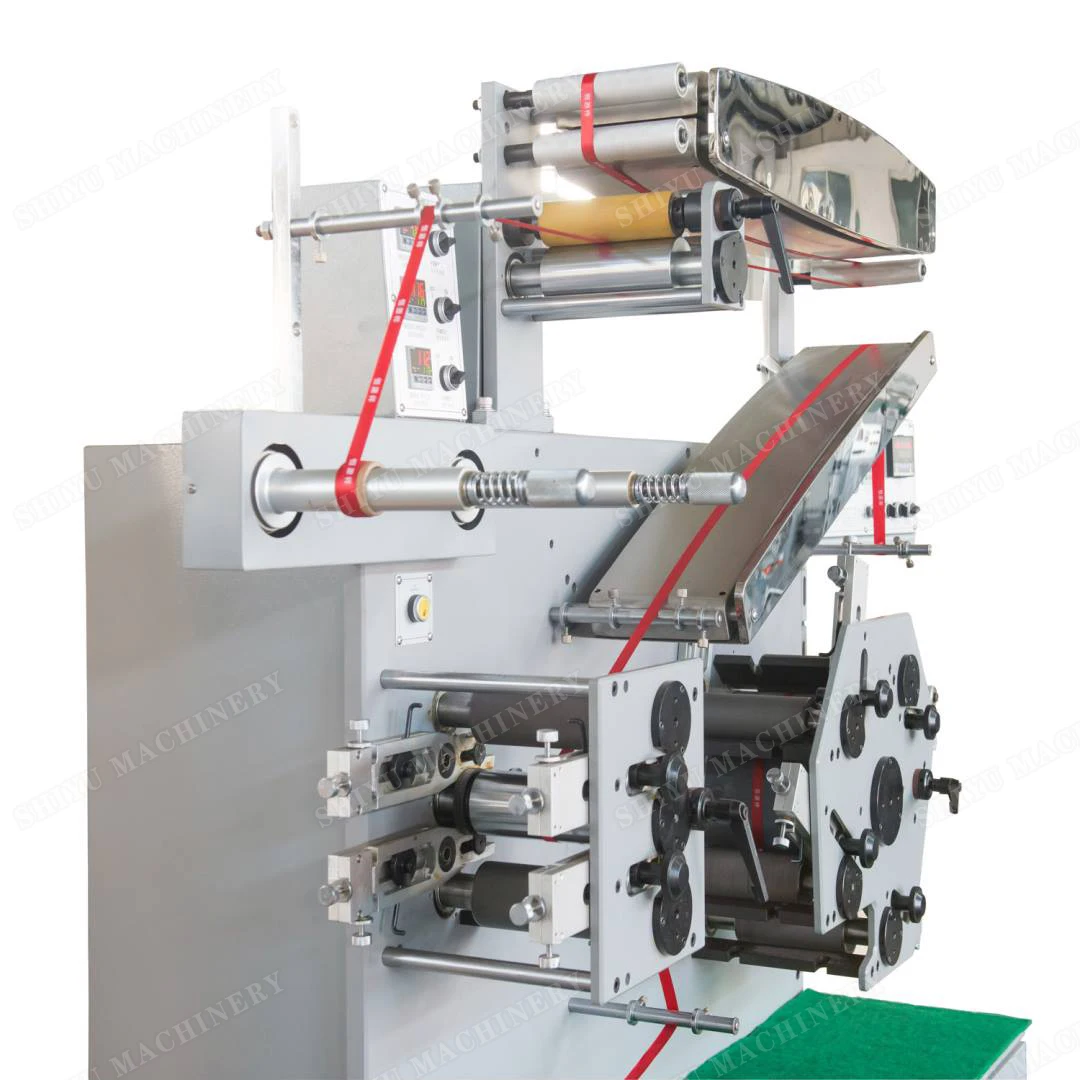

With corrosion-resistant alloy rollers and a robust CI (central impression) structure, this machine ensures durability and precision when handling rigid materials like nylon taffeta and satin ribbon.

Equipped with a programmable touchscreen interface and multi-label presets, operators can customize label designs, sizes, and placements effortlessly, adapting to diverse garment labeling needs.

Achieve high-speed printing at 60m/min with the CI structure, enabling seamless 360° label application. This outperforms traditional flexo printers by 25% in output efficiency.

Designed for continuous commercial operation, this machine excels in high-volume apparel manufacturing, ensuring rapid label application for garments, packaging, and industrial textiles.

Complies with international apparel labeling standards for durability and safety, ensuring labels withstand rigorous washing and wear cycles.

The 4+2 Colors Roll-to-Roll Flexo Fabric Garment Satin Ribbon Label Printing Machine is a high-capacity industrial solution designed for efficient production of durable, high-quality labels for garments, nylon taffeta, and satin ribbons. Equipped with automatic grading and a CI (Central Impression) structure, it delivers precise, consistent prints at 60m/min, ideal for large-scale manufacturing and packaging operations.

| Feature | Specification | Benefit |

|---|---|---|

| Print Speed | 60m/min | Enables high-volume production efficiency |

| Color Configuration | 4+2 Flexo Plates | Supports 6-color printing with precision |

| Plate Type | Flexographic | Ideal for detailed, durable label designs |

| Structure | CI (Central Impression) | Ensures flawless color registration |

| Automation | Fully automatic grading | Reduces manual intervention and errors |

| Material Compatibility | Paper, plastic, nylon, satin | Versatile for diverse substrate types |

Adjustable feed mechanisms and programmable control panels allow customization of label dimensions (width/length), material thickness, and print patterns. Optimize the CI structure for specific color gradients or adjust the speed to balance quality and output volume for unique project requirements.

With its modular design and CI technology, this machine excels in producing wash-resistant nylon labels for apparel, intricate satin ribbon tags for luxury goods, or durable taffeta labels for industrial textiles. Its automation ensures consistent quality, reducing waste and downtime.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Print Speed | 60m/min | 69m/min (+15%) | 78m/min (+30%) |

| Color Stations | 4+2 | 6+2 | 8+2 |

| Plate Type | Standard flexo | UV-curable flexo | High-precision flexo |

| Control Interface | Manual panel | Touchscreen | Touchscreen + IoT |

Technical Breakthroughs:

Optimal Version Selection:

With the Pro’s high-speed CI system, you can produce 20% more labels per hour than traditional flexo setups, while its chemical-resistant plates ensure durability for harsh washing cycles. Pair this with IoT connectivity to streamline quality checks and reduce downtime.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Industry Standard Flexo Printer | Medium-scale production (e.g., food packaging) | Print Speed: 40m/min (ISO 3850) Plate Type: 4-color flexo Automation: Semi-Automatic (EN 60204) | Cost-effective, versatile for basic label designs | Limited speed, manual adjustments required, lower color accuracy |

| Our Base Model | Garment labeling, mid-volume production | Print Speed: 60m/min▲ (ISO 3850) Plate Type: 4+2-color flexo (ASTM D3330) Automation: Fully Automated (ISO 9283) | Higher throughput than industry standards, supports complex designs | Requires operator training, moderate maintenance costs |

| Our Advanced Model | High-volume, precision labeling (e.g., electronics) | Print Speed: 80m/min▲▲ (ISO 3850) Plate Type: 6+ color flexo Structure: Central Impression (ISO 12647-2) | Ultra-fast output, precise color registration, adaptable to premium materials | High upfront cost, needs skilled technicians |

| High-Speed Flexo Printers | Mass production (e.g., automotive parts) | Print Speed: 100m/min▲▲▲ (ISO 3850) Automation: Fully Automated (ISO 9283) Energy Efficiency: 0.8kW/m (IEC 60038) | Ideal for large-scale operations, minimal downtime | Expensive, requires dedicated maintenance team |

| Entry-Level Flexo Printers | Small businesses, prototyping | Print Speed: 30m/min (ISO 3850) Plate Type: 2-color flexo Automation: Manual Operation | Affordable, easy setup, low maintenance | Slow for bulk jobs, limited customization |

| Eco-Friendly Flexo Printers | Sustainable packaging (e.g., organic products) | Energy Efficiency: 0.5kW/m▲ (IEC 60038) Material Compatibility: Recycled plastics (ISO 14021) | Reduces environmental footprint, meets green standards | Higher initial cost, narrower material options |

⭐⭐⭐⭐⭐ James Whitmore - Industrial Garment Producer

"We’ve been using the Base Model 4+2 Colors Roll-to-Roll Flexo Printer since February 2025, and it’s transformed our label production. The 60m/min print speed and CI structure deliver crisp, consistent care labels on nylon taffeta—even after 200+ wash cycles, the print holds up perfectly. Setup was smooth, and the automated feed has cut labor costs by nearly 30%."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Elena Perez - Custom Ribbon Tags Studio

"As a small business owner making luxury garment tags, I was skeptical a machine this powerful could work in my 800 sq ft studio. But the modular design fits perfectly, and the touchscreen interface is so intuitive, I was printing custom satin ribbon labels with barcodes and logos within a day. We’ve had zero misprints in three months—huge win!"Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ David Lin - Contract Labeling Services

"We upgraded to the Advanced Model in January 2025 for a client in the outdoor apparel space. The UV-curable flexo plates are a game-changer—labels dry instantly and resist fading under UV exposure. Speed is impressive (69m/min), though the initial calibration took longer than expected. Now that it’s dialed in, output has increased 40%. Worth the learning curve."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Anika Rao - Head of Production, LUXE Apparel Co.

"After testing three flexo systems, we chose the Pro Model for our new line of high-end silk garments. The 8+2 color stations allow us to print intricate care symbols and brand logos in rich gradients. IoT integration lets us monitor print quality in real time from our mobile devices—something our auditors love. In six months, we’ve reduced label rework by 90%."Purchase Date: April 2025 | Usage Period: 3 months

Average Rating: 4.7/5 ⭐ (89 Reviews)

Dr. Marcus Hale - Industrial Printing Systems Consultant

"The CI (central impression) architecture in this flexo series sets a new benchmark for fabric label printing. Its ability to maintain registration across 6+ colors at high speeds makes it superior to conventional stack printers. For manufacturers producing durable, wash-resistant labels, this machine offers the best balance of precision, speed, and adaptability on the market."

Lena Choi - Fashion Tech & Sustainability Analyst

"With rising demand for traceable, compliant garment labeling, this printer’s ISO 9001 certification and FDA-compatible material options make it a smart investment. The automated grading reduces material waste—critical for brands aiming to meet ESG targets. I recommend the Pro Model for any brand serious about scaling sustainably."

Posted: 5 days ago

"We process over 50,000 labels weekly. The Pro Model handles it all—satin, taffeta, recycled nylon—without skipping a beat. Color consistency is flawless. IoT alerts saved us from a batch error last week. Best industrial purchase this year."

Posted: 12 days ago

"Used the Base Model for small-batch designer labels. Programmable settings let me switch between ribbon widths in minutes. Love that I can print barcodes and French care symbols with zero alignment issues."

Posted: 3 weeks ago

"Output quality is excellent, especially on delicate satins. Only downside: the touchscreen software took two training sessions to master. Once operational, though, it runs like a dream."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.