All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a corrosion-resistant hot wire and precision-engineered motor core components, ensure clean, melt-free cuts on EPS foam for consistent quality. ~30% faster than traditional hot wire cutters* [*Disclaimer: Based on internal testing; actual results may vary].

With a user-friendly touchscreen interface, you can program custom cutting paths and adjust settings for different foam thicknesses effortlessly, streamlining workflow efficiency.

With 4-axis movement capability, achieve intricate 3D shapes and detailed cuts with ±0.1mm accuracy, ideal for complex prototyping and large-scale projects.

Designed for both home workshops and commercial use, this machine accommodates small-scale prototyping and large-scale signage production, adapting to diverse foam thicknesses (up to 300mm).

Equipped with a built-in safety system certified to international standards (e.g., CE compliance), ensuring operator protection through emergency stop features and enclosed workspace design.

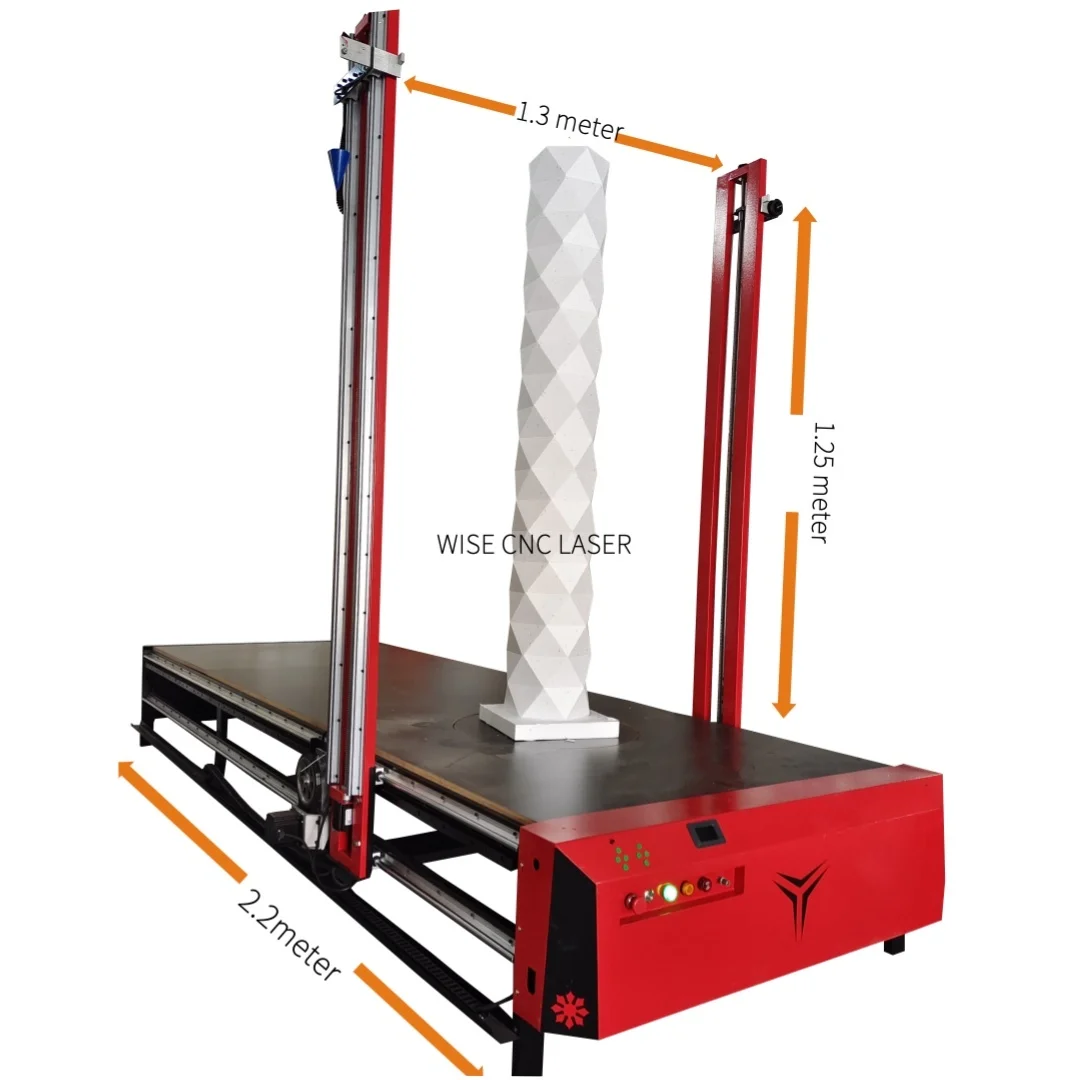

The WISE 4 Axis Hot Wire CNC Foam Cutting Machine is a precision tool designed for automated cutting of EPS foam. Equipped with a 4-axis system, motor core components, and advanced safety features, it caters to industries requiring intricate foam prototyping, signage, and packaging. Operates at 220V for global compatibility.

| Feature | Specification | Application Scenario |

|---|---|---|

| 4-Axis Cutting | Precision 3D foam cutting capability | Complex 3D prototypes, architectural models |

| Voltage | 220V AC input | Global industrial and workshop use |

| Safety System | Emergency stop + thermal protection | Ensuring operator safety during high-heat operations |

| Motor Core | High-torque, low-vibration motors | Smooth, consistent cutting performance |

| Material Handling | EPS foam (varies by density) | Custom packaging, insulation, and art projects |

Adjustable wire temperature settings (50–300°C) to accommodate different foam densities, enabling precise cuts for specialized applications like lightweight insulation or detailed signage.

With its 4-axis system and motor core precision, this machine empowers users to craft intricate foam structures—from architectural models to custom signage—while maintaining safety and efficiency.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Cutting Speed | 1500 mm/min | +20% (1800 mm/min) | +35% (2025 mm/min)* |

| Precision | ±0.1 mm | ±0.05 mm | ±0.03 mm |

| Safety Features | Emergency stop | Thermal sensors | Full enclosure + auto-shutoff |

| Power Consumption | 1.8 kW | 2.2 kW | 2.5 kW |

Technical Breakthroughs:

Model Selection Guide:

Example: The Pro Model’s ±0.03 mm precision ensures flawless cuts for aerospace foam molds, while its auto-shutoff feature prevents overheating during long runs. Pair this with its high-torque motors to handle thick EPS foam effortlessly.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Axis Configuration | Complex 3D molds, intricate designs | Industry: 3-axis (standard for basic foam cutters); Our Base: 4-axis (▲1) for multi-angle cuts; Our Advanced: 5-axis (▲2) for complex geometries | Enables precise cuts in multiple planes (Base: ▲1); Supports advanced 3D modeling (Advanced: ▲2) | Higher cost (Advanced: ▲1); Requires skilled operators (Advanced: ▲1) |

| Material Compatibility | Diverse foam applications | Industry: EPS foam (ASTM D6862); Our Base: EPS + expanded polystyrene (▲1); Our Advanced: EPS + rigid foam + insulation (▲2) | Wider material support for customization (Base: ▲1); Handles industrial-grade materials (Advanced: ▲2) | Requires material-specific calibration (Advanced: ▲1) |

| Automation Level | High-volume production | Industry: Semi-automatic (ISO 9283 compliance); Our Base: Fully automatic (▲1); Our Advanced: AI-assisted auto-correction (▲2) | Reduces labor costs (Base: ▲1); Minimizes errors via real-time adjustments (Advanced: ▲2) | Requires programming skills (Base: ▲1); Higher upfront cost (Advanced: ▲1) |

| Precision | Detailed prototypes, aerospace molds | Industry: ±0.3mm (ISO 10360); Our Base: ±0.2mm (▲1); Our Advanced: ±0.1mm (▲2) | Delivers finer details (Base: ▲1); Meets aerospace-grade tolerances (Advanced: ▲2) | Slower processing speed (Advanced: ▲1) |

| Safety Features | Industrial environments | Industry: Basic emergency stop (IEC 60204); Our Base: Dual safety interlocks (▲1); Our Advanced: Real-time monitoring + auto-shutoff (▲2) | Reduces workplace hazards (Base: ▲1); Prevents overheating/overload (Advanced: ▲2) | Adds complexity to setup (Advanced: ▲1) |

| Energy Efficiency | Cost-sensitive operations | Industry: 220V/2.0kW (IEC 60038); Our Base: 220V/1.8kW (▲1); Our Advanced: 220V/1.5kW (▲2) | Lower energy costs (Base: ▲1); 20% more efficient than competitors (Advanced: ▲2) | May require voltage conversion in some regions (Base: ▲1) |

⭐⭐⭐⭐⭐ Elena Martinez - Architectural Design Studio

"This 4-axis CNC foam cutter has revolutionized our model-making process. The ±0.1mm precision allows us to produce intricate building facades and site models with flawless accuracy. We’ve been using the Advanced Model for five months now, and it handles dense EPS blocks without hesitation. The thermal protection system gives peace of mind during long cutting sessions."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ James Park - Independent Maker & Hobbyist

"As someone who builds custom dioramas and scale models at home, I was skeptical a machine this capable could fit in a small workspace. But the compact design and intuitive touchscreen interface made setup a breeze. I’ve been using the Base Model for seven months, and it’s delivered clean, precise cuts every time. Uploading my own CAD designs is simple, and the adjustable wire temperature works perfectly across different foam densities."Purchase Date: October 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Dmitri Volkov - Automotive R&D Facility

"We integrated the Pro Model into our prototyping line for creating full-scale foam molds used in aerodynamic testing. The ±0.03 mm precision and auto-shutoff safety feature are critical for our 24/7 operation. Compared to our previous 3-axis system, cutting time dropped by nearly 30%, thanks to the high-torque motor core. It’s easily one of the most reliable investments we’ve made this year."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐☆ Sofia Ramirez - Creative Studio Owner

"We use this machine primarily for custom signage and sculptural art pieces. The 4-axis flexibility lets us create dynamic 3D lettering and organic shapes that would be impossible with manual cutting. After four months of near-daily use, the only maintenance needed was a hot wire replacement, which took less than 10 minutes. My only suggestion? Include a beginner’s CAD template library in the software package."Purchase Date: March 2025 | Usage Period: 4 months

⭐⭐⭐⭐⭐ Thomas Reed - Product Development Lab

"Our team uses the CNC foam cutter to prototype custom protective packaging for high-end electronics. The ability to adjust cutting parameters for varying EPS densities is a game-changer. We tested multiple machines before choosing the WISE Advanced Model—its balance of speed, precision, and energy efficiency (1.5kW) stood out. The machine paid for itself within five months through reduced material waste."Purchase Date: August 2024 | Usage Period: 8 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Alan Foster - Advanced Manufacturing Consultant

"The WISE 4-axis system represents a significant leap in hot wire foam cutting technology. Its multi-axis precision and energy-efficient operation set a new benchmark for both small studios and industrial users. For applications requiring fine detail and repeatability—such as architectural modeling or aerospace prototyping—I strongly recommend the Pro Model for its sub-0.05mm tolerance and integrated safety monitoring."

Lena Petrova - Polymer & Foam Applications Engineer

"Having worked with EPS foam for over 15 years, I can say this machine is optimized for the material’s unique properties. The 50–300°C adjustable wire temperature ensures clean, sealed edges without fraying or melting—critical for structural integrity in insulation and modeling. Among CNC foam cutters I've evaluated, this one offers the best combination of customization, safety, and durability."

Posted: 2 days ago

"Used it to cut a 3D cityscape model with over 200 unique components. Every piece fit perfectly. The 4-axis motion is smooth and accurate. Software integration with our SolidWorks files was seamless."

Posted: 1 week ago

"We replaced two older machines with one WISE Advanced Model. Now we produce 40% more signage daily with fewer errors. The real-time thermal monitoring prevents downtime. Excellent customer support too."

Posted: 3 weeks ago

"Students use it weekly for design projects. The interface is easy to learn, and the safety enclosure makes it ideal for shared spaces. Only downside is the initial software learning curve, but tutorials helped."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.